A street trench dredging device for natural gas pipeline laying

A technology for natural gas pipelines and streets, applied in construction, earth movers/excavators, etc., can solve problems such as inability to remove dust in time, achieve the effect of saving manpower and material resources and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

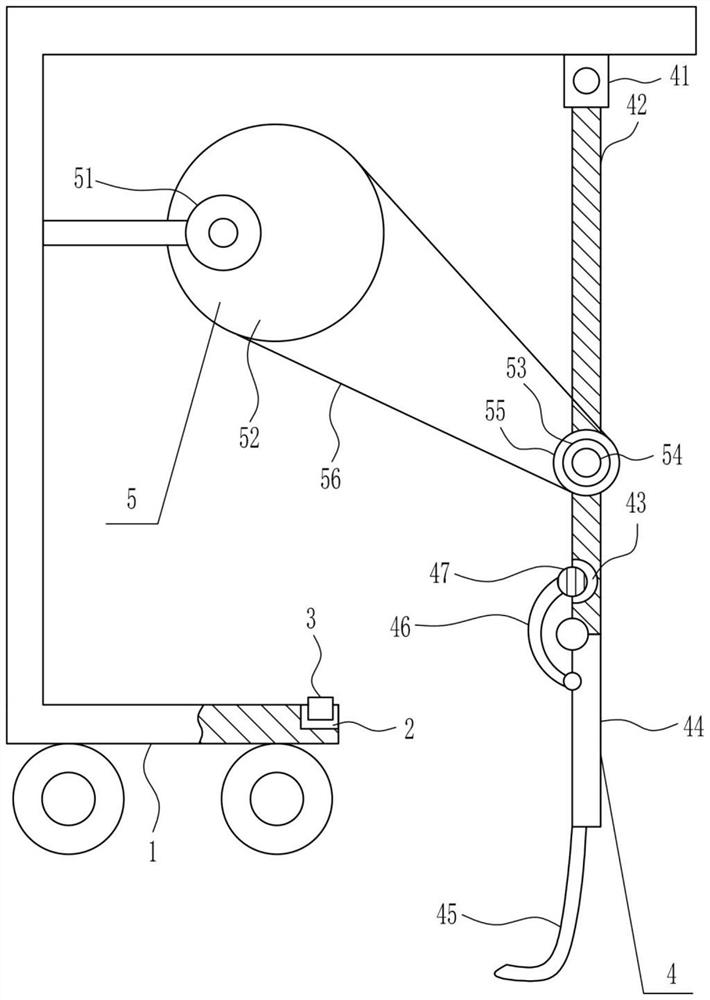

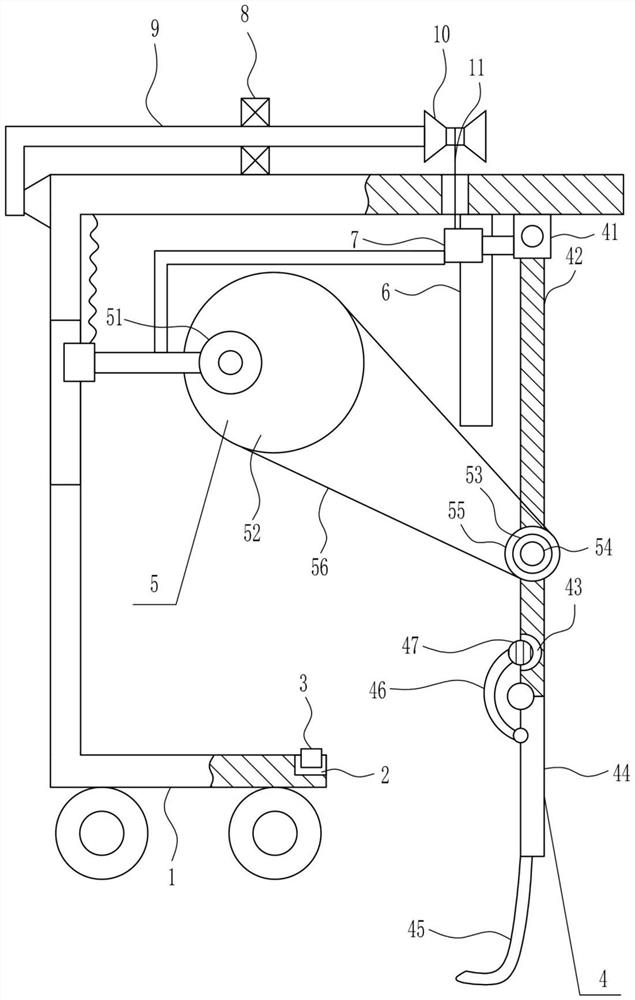

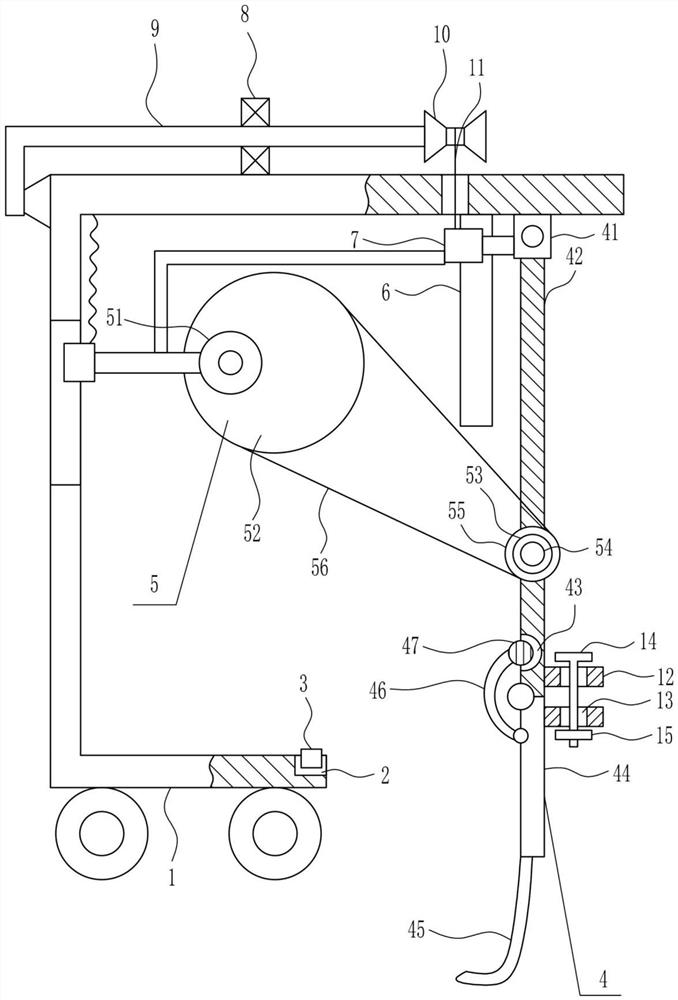

[0032] A street trench dredging device for natural gas pipeline laying, such as Figure 1-5 As shown, it includes a trolley 1, a stopper 3, an excavating mechanism 4 and a drive mechanism 5. There is a chute 2 on the right side of the bottom of the trolley 1, and a stopper 3 is arranged on the chute 2. The chute 2 cooperates with the stopper 3. The right part of the trolley 1 is provided with an excavating mechanism 4, and the top left part of the trolley 1 is provided with a driving mechanism 5, and the driving mechanism 5 cooperates with the excavating mechanism 4.

Embodiment 2

[0034] A street trench dredging device for natural gas pipeline laying, such as Figure 1-5 As shown, it includes a trolley 1, a stopper 3, an excavating mechanism 4 and a drive mechanism 5. There is a chute 2 on the right side of the bottom of the trolley 1, and a stopper 3 is arranged on the chute 2. The chute 2 cooperates with the stopper 3. The right part of the trolley 1 is provided with an excavating mechanism 4, and the top left part of the trolley 1 is provided with a driving mechanism 5, and the driving mechanism 5 cooperates with the excavating mechanism 4.

[0035] The excavating mechanism 4 includes a mounting block 41, a swing rod 42, a connecting rod 44, a shovel 45, a clamp rod 46 and a rubber ball 47. The right side of the top of the trolley 1 is connected with the mounting block 41, and the bottom of the mounting block 41 is connected with a swing rod 42 in a rotating manner. There is a circular groove 43 on the left side of the lower part of the swing rod 42,...

Embodiment 3

[0037] A street trench dredging device for natural gas pipeline laying, such as Figure 1-5 As shown, it includes a trolley 1, a stopper 3, an excavating mechanism 4 and a drive mechanism 5. There is a chute 2 on the right side of the bottom of the trolley 1, and a stopper 3 is arranged on the chute 2. The chute 2 cooperates with the stopper 3. The right part of the trolley 1 is provided with an excavating mechanism 4, and the top left part of the trolley 1 is provided with a driving mechanism 5, and the driving mechanism 5 cooperates with the excavating mechanism 4.

[0038] The excavating mechanism 4 includes a mounting block 41, a swing rod 42, a connecting rod 44, a shovel 45, a clamp rod 46 and a rubber ball 47. The right side of the top of the trolley 1 is connected with the mounting block 41, and the bottom of the mounting block 41 is connected with a swing rod 42 in a rotating manner. There is a circular groove 43 on the left side of the lower part of the swing rod 42,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com