Plug-and-play anti-seismic energy dissipation device suitable for fabricated frame structure

A frame structure, plug-and-play technology, applied in the direction of earthquake resistance, building components, protective buildings/shelters, etc., can solve the problems of immature development, easy damage, weakened mechanical performance of nodes, etc., and reach the level of industrialization High, large lateral stiffness and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, the concrete columns are side columns.

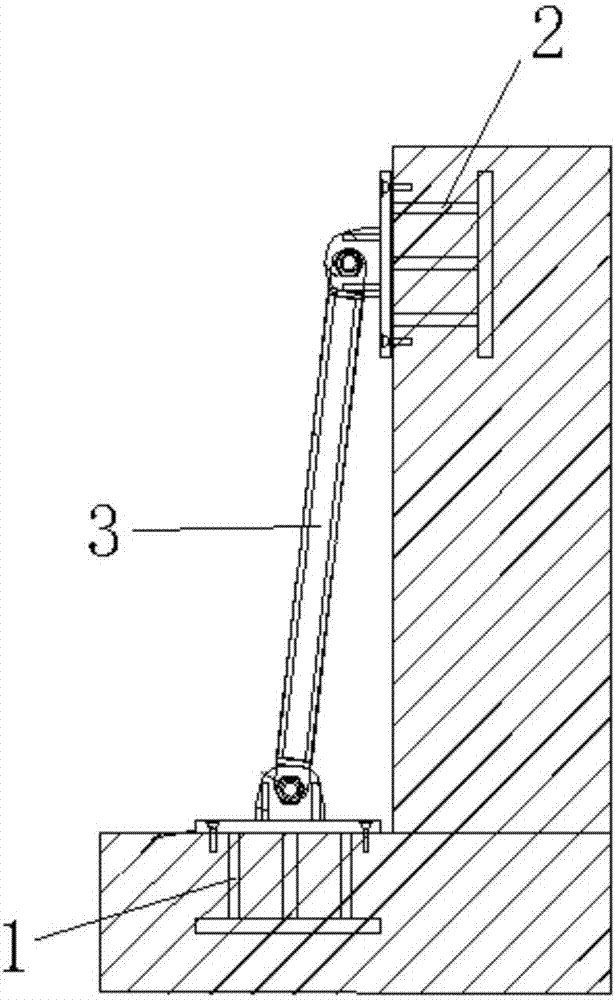

[0027] Such as Figure 1 to Figure 3 As shown, the plug-and-play anti-seismic energy dissipation device of the present invention suitable for prefabricated frame structures includes support seat I1 embedded in the concrete foundation, support seat II2 embedded in the concrete column, and connecting support seat I and The energy dissipation damping device 3 of the support seat II;

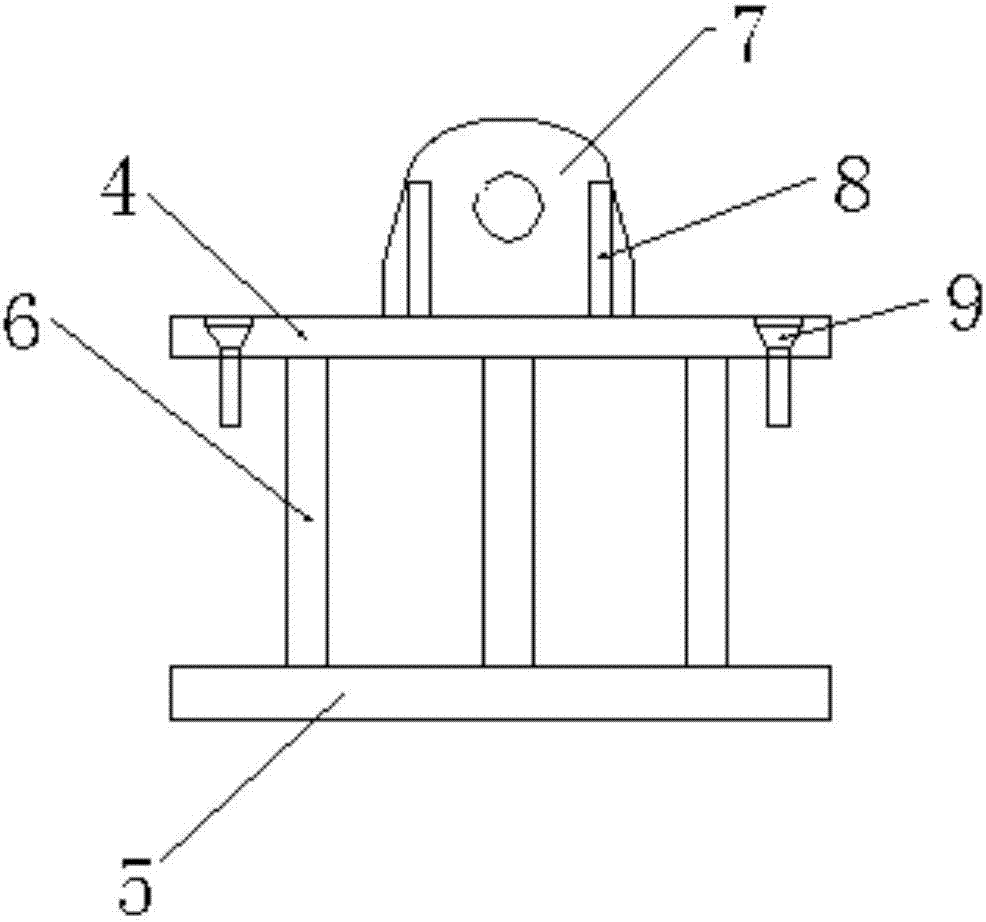

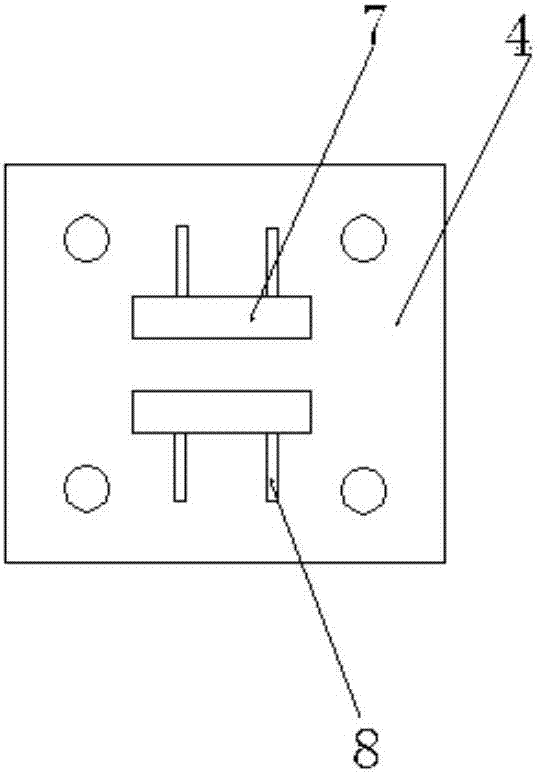

[0028] The support seat I and the support seat II have the same structure, both of which include parallel upper anchor plate 4 and lower anchor plate 5, the upper anchor plate and the lower anchor plate are connected by straight anchor ribs 6, and the upper anchor plate is provided with ear plate I7; The lug I includes two parallel lugs, and the outer sides of the two lugs are provided with stiffening ribs 8 for enhancing the stability and torsional performance of the lugs. Since the diameter of the straight anchor bar is greater ...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that the concrete column is not a side column. In this case, the support seat I in the concrete column should be connected to the support seat II on both sides through the energy dissipation damping device. Two supporting seats I are pre-embedded in the concrete column to realize the connection with the supporting seats II on both sides. In order to simplify the construction steps, the two support bases I can also be combined into one, such as Image 6 As shown, the support base I includes three parallel anchor plates, the anchor plates are connected by straight anchor bars, and the two outer anchor plates are welded with ear plates I, and the ear plate I is connected with the ear plate II.

[0036] Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com