Tail spring device of drum vacuum valve

A technology of vacuum valve and spring device, which is applied in the field of uranium enrichment, can solve the problems of easily damaged welds and hidden dangers of valve reliability, and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

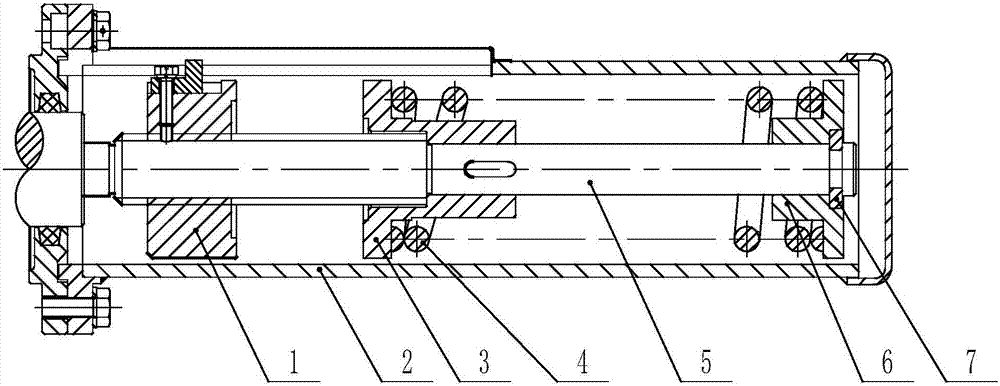

[0019] Such as figure 1 As shown, the tail spring device of a drum vacuum valve in the present invention connects the sleeve assembly to the external system through bolts, including a worm shaft, a nut assembly, a spring assembly and a sleeve assembly;

[0020] The nut assembly consists of a nut and a slider. The slider is an L-shaped plate. The trapezoidal thread part at the end of the worm shaft is connected to the slider through screws and nuts in the length direction of the slider. The slider is stuck on the sleeve in its height direction. In the U-shaped groove of the component to limit the rotational movement of the nut component;

[0021] When the worm shaft rotates, the nut assembly does not rotate with the worm, but slides along the axial direction of the worm shaft, and at the same time slides linearly alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com