Coal seam floor hidden water inrush subsided column dynamic positioning method

A dynamic positioning and coal seam floor technology, applied in the field of geophysical exploration, can solve the problems of small collapsed columns and hidden collapsed columns that are difficult to detect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

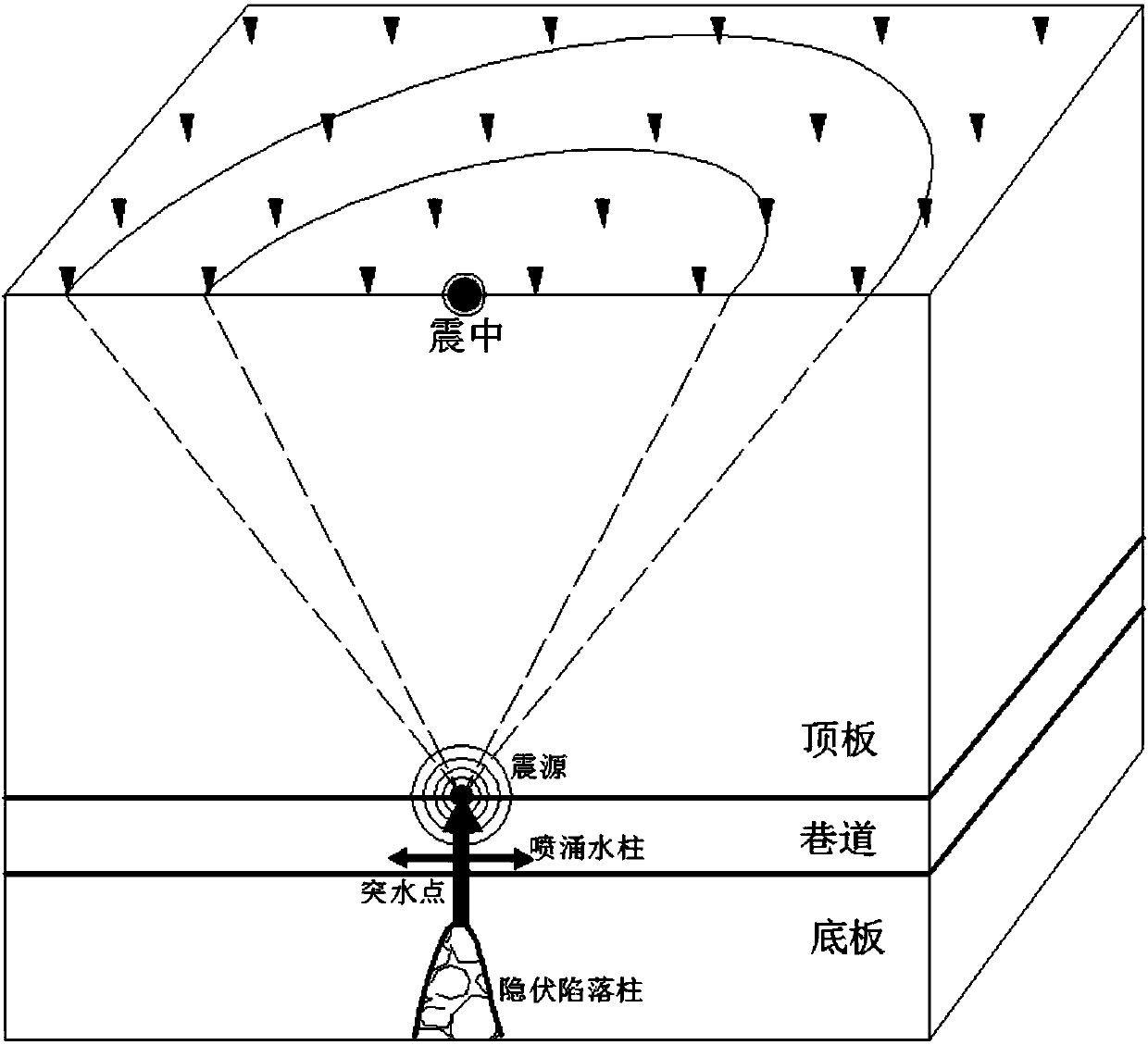

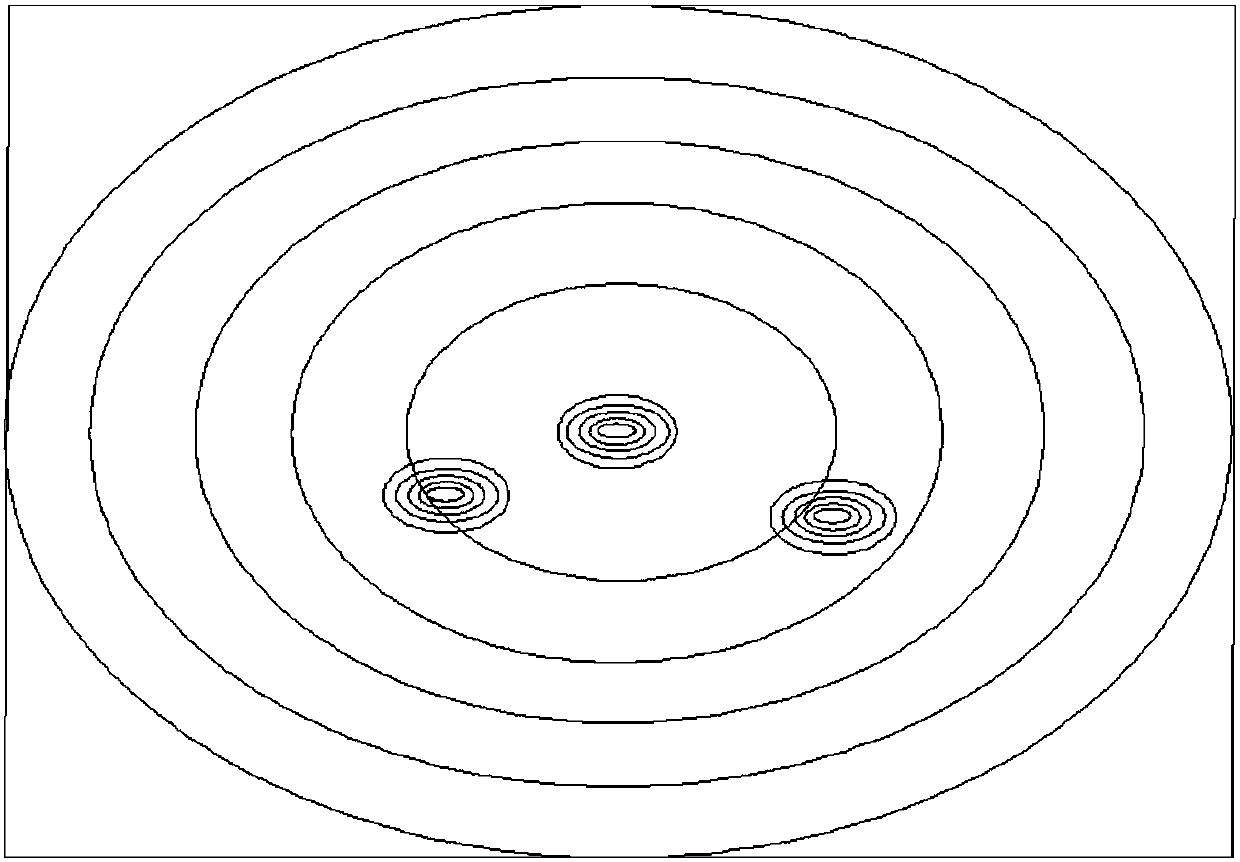

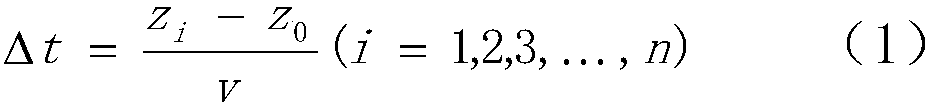

[0053] The water inrush flooded the well in Mine T. Through the hydrological monitoring hole, it was preliminarily determined that the source of the water inrush was Austrian ash water, and it was speculated that the channel of the water inrush was a collapsed column. When the high-pressure Austrian ash water inrushes from the coal seam floor, the water inrush point will hit the roof of the roadway to form a "secondary seismic source". Using ground microseismic monitoring technology, long-term and dynamic microseismic monitoring and rapid positioning are carried out near the water inrush subsidence column to determine There were 2 suspected water inrush points. Through drilling verification, the position of the subsidence column determined by the microseismic is 26m away from the drilling control point, and the water inrush point is a hidden small subsidence column 77m below the coal seam floor, which is 19m×7m.

[0054] This embodiment proposes a method for locating a hidden ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com