High-toughness photosensitive epoxy acrylic resin composition capable of developing in weakly basic water and preparation method of epoxy acrylic resin composition

A technology of epoxy acrylic and resin composition, which is applied in the direction of photosensitive materials for photomechanical equipment, photomechanical equipment, photoplate making process of patterned surface, etc., which can solve the problems of high product cost, poor dispersion and heat resistance. Poor property and alkali resistance, etc., to achieve the effect of electrical insulation balance, enhanced toughness, and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

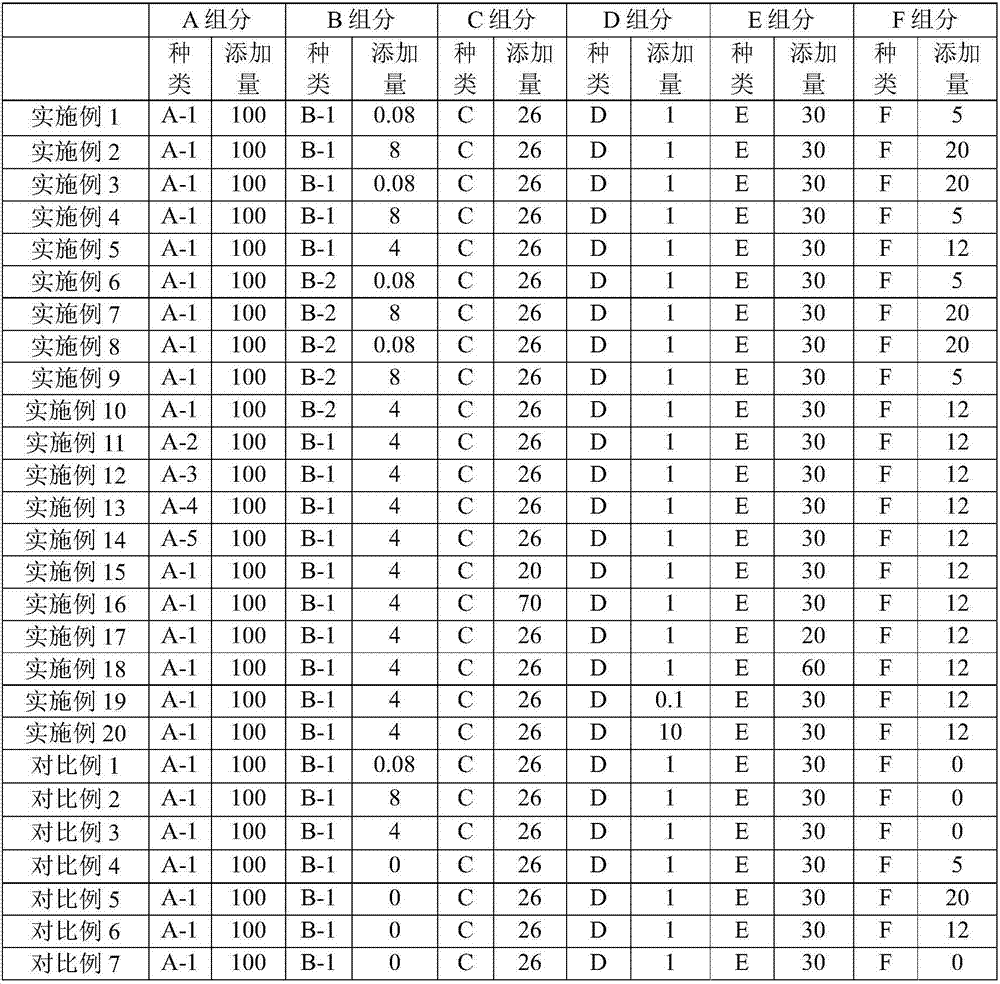

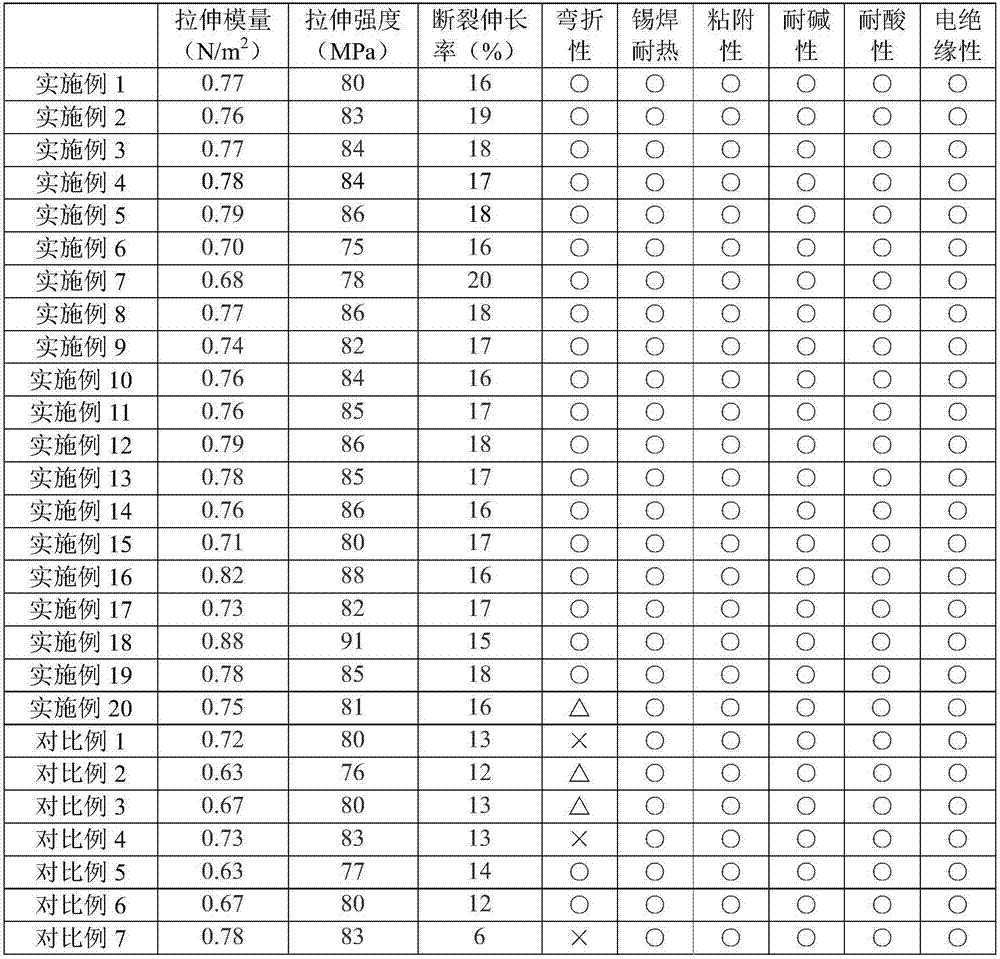

Examples

Embodiment 1

[0028] (1) Preparation of alkali-soluble epoxy acrylic resin

[0029] Under a nitrogen atmosphere, add 0.27 mol of tetrahydrophthalic anhydride, 0.0046 mol of pyridine, and 0.0007 mol of hydroquinone monomethyl ether to 100 parts of epoxy acrylic resin, heat the mixture to 90°C, react for 6 hours and then cool to obtain a solid content of 67 wt. %, acid value 90mgKOH / g alkali-soluble epoxy acrylic resin, denoted as A-1.

[0030] (2) Preparation of photosensitive epoxy acrylic resin composition glue

[0031] Add to 100 parts of alkali-soluble epoxy acrylic resin

[0032] 0.08 part tetrahydrofuran acrylate;

[0033] 26 parts of multifunctional acrylate monomers, which include tripropylene glycol diacrylate, ethoxylated trimethylolpropane triacrylate, and 1,6-hexanediol diacrylate, and the mass ratio of the three is 2: 3:3;

[0034] 1 part of photoinitiator, including photopolymerization initiator 2-methyl-1-[4-(methylthio)phenyl]-2-morpholino-acetone-1, 0.994 parts, photosen...

Embodiment 2

[0039] (1) Alkali-soluble epoxy acrylic resin adopts resin A-1 synthesized in embodiment 1;

[0040] (2) Preparation of photosensitive epoxy acrylic resin composition glue:

[0041] Add to 100 parts of alkali-soluble epoxy acrylic resin

[0042] 8 parts tetrahydrofuran acrylate;

[0043] 26 parts of multifunctional acrylate monomers, including tripropylene glycol diacrylate, ethoxylated trimethylolpropane triacrylate, and 1,6-hexanediol diacrylate, the mass ratio of the three monomers is 2 :3:3;

[0044]1 part of photoinitiator, including photopolymerization initiator 2-methyl-1-[4-(methylthio)phenyl]-2-morpholino-acetone-1, 0.0993 parts, photosensitizer 2-isopropyl 0.0007 part of thioxanthone, the weight ratio of the two is 150:1;

[0045] 30 parts bisphenol A epoxy resin;

[0046] 20 parts of nano core-shell rubber toughened resin;

[0047] Stir at room temperature to promote its dissolution, filter to obtain the glue solution of the photosensitive epoxy acrylic resin ...

Embodiment 3

[0049] (1) Alkali-soluble epoxy acrylic resin adopts resin A-1 synthesized in embodiment 1;

[0050] (2) Preparation of photosensitive epoxy acrylic resin composition glue:

[0051] Add to 100 parts of alkali-soluble epoxy acrylic resin

[0052] 0.08 part tetrahydrofuran acrylate;

[0053] 26 parts of multifunctional acrylate monomers, including tripropylene glycol diacrylate, ethoxylated trimethylolpropane triacrylate, 1,6-hexanediol diacrylate, the mass ratio of the three is 2:3 :3;

[0054] 1 part of photoinitiator, including photopolymerization initiator 2-methyl-1-[4-(methylthio)phenyl]-2-morpholino-acetone-1, 0.0995 parts, photosensitizer 2-isopropyl 0.0005 part of thioxanthone, the weight ratio of the two is 200:1;

[0055] 30 parts bisphenol A epoxy resin;

[0056] 20 parts of nano core-shell rubber toughened resin;

[0057] Stir at room temperature to promote its dissolution, filter to obtain the glue solution of the photosensitive epoxy acrylic resin compositio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com