A track grounding device

A grounding device and track technology, applied in the direction of connecting contact materials, locomotives, etc., can solve the problems of excessive grounding resistance and small grounding current return, and achieve the effects of prolonging service life, reducing high-frequency impedance, and reducing electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

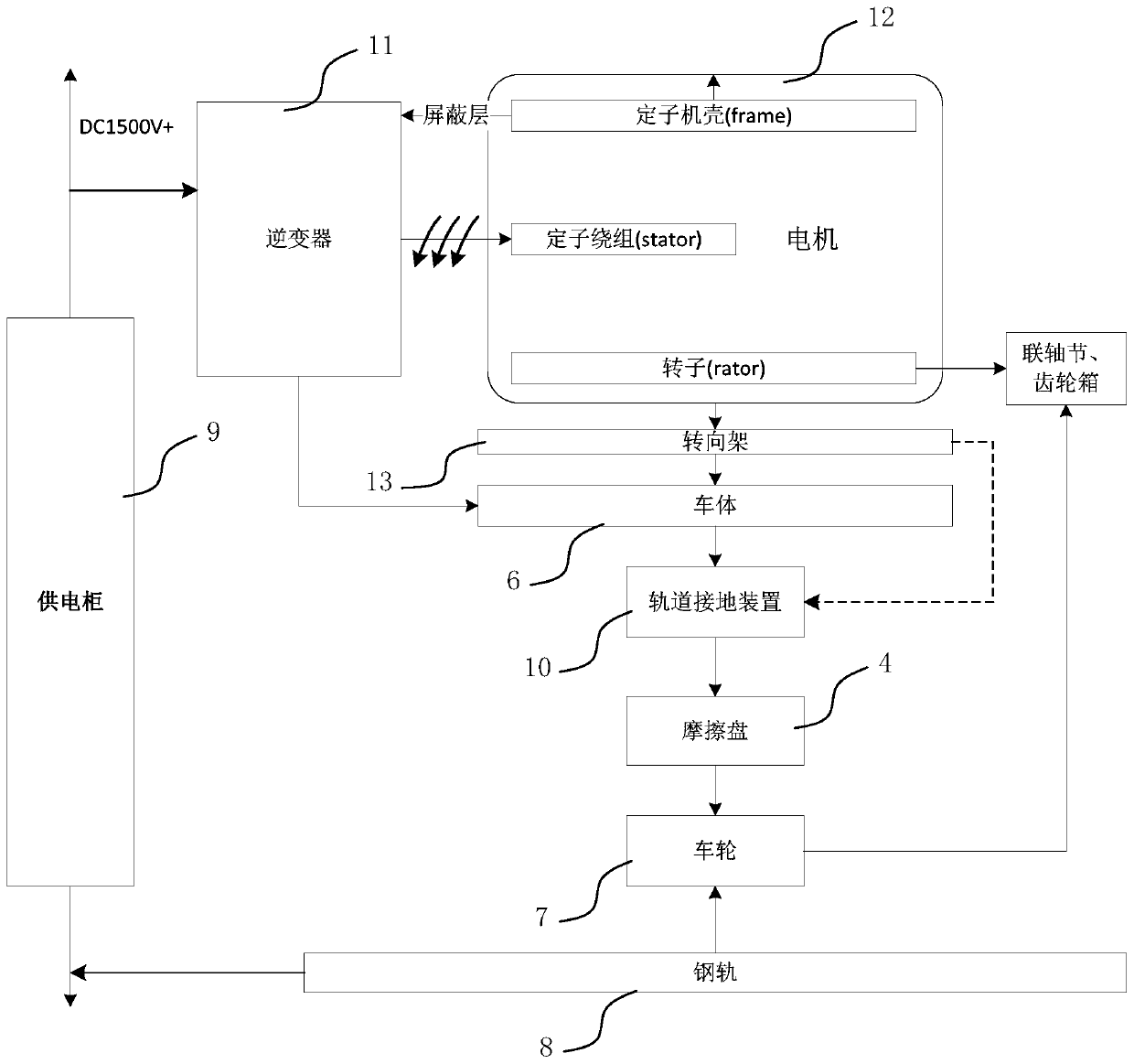

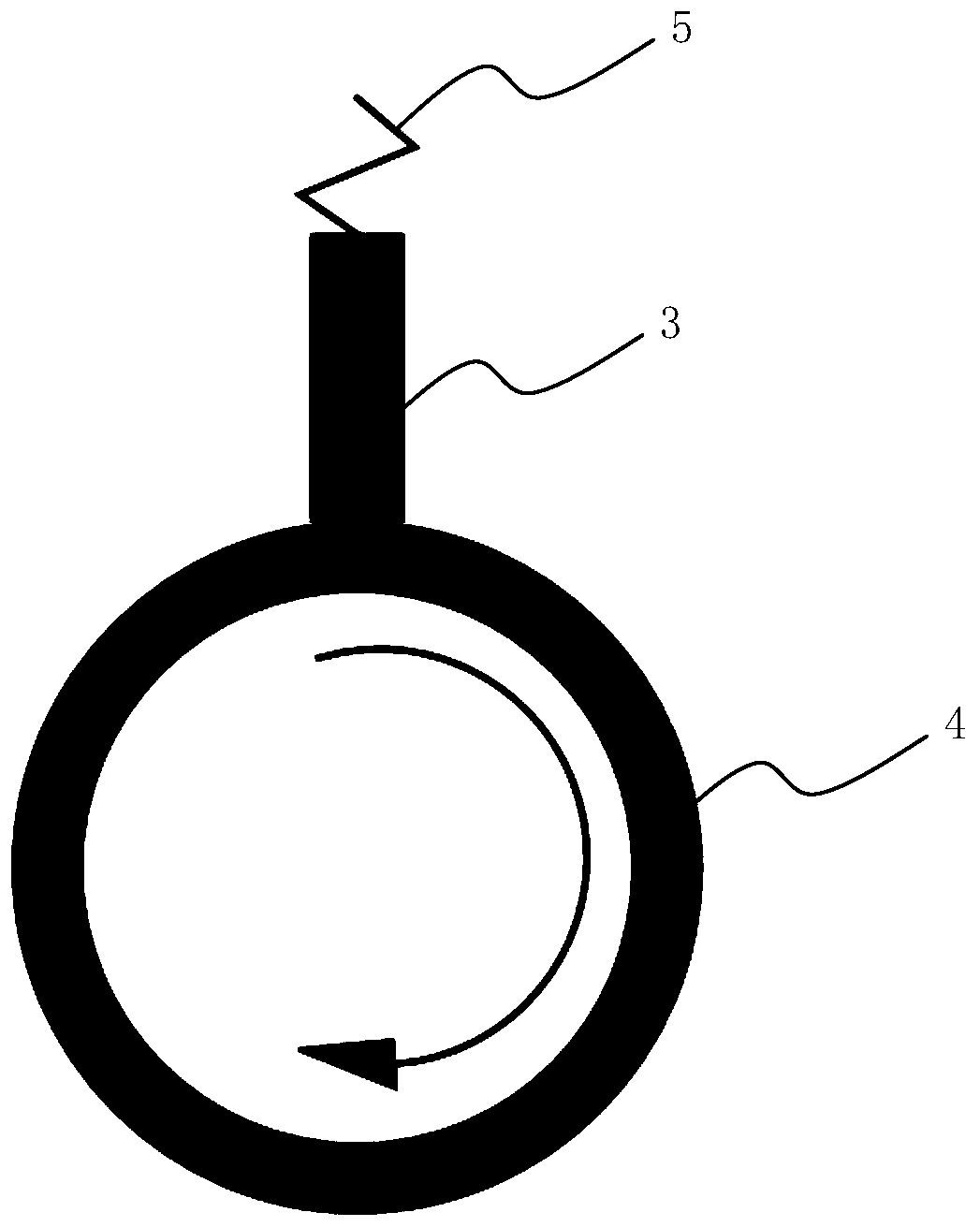

[0051] as attached Figure 4 As shown, a specific embodiment of the track grounding device, the track grounding device 10 is connected between the car body 6 and the friction disc 4, and is used to conduct the electrical connection between the car body 6 and the rail 8 to realize the grounding function. Grounding device 10 includes:

[0052] The rigid brush 3 connected to the car body 6 through the elastic mechanism 5, the rigid brush 3 is in rigid contact with the friction disc 4;

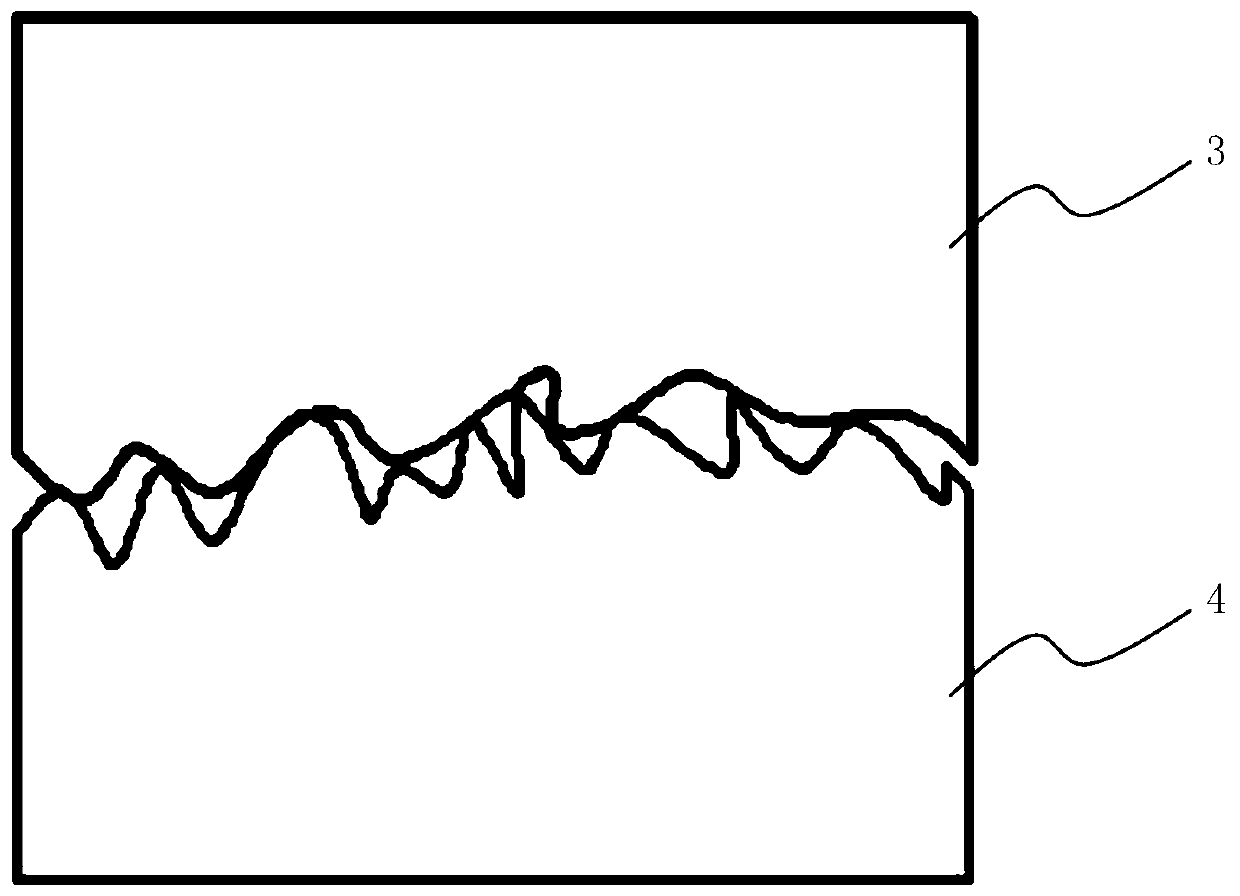

[0053] The flexible brush 1 connected to the rigid brush 3, the flexible brush 1 further includes a base 2 fixedly connected to the rigid brush 3, and a brush wire 20 connected to the base 2, the brush wire 20 is in elastic contact with the friction disc 4 , as attached Figure 6 shown. The base 2 can be reliably connected (including mechanical connection and electrical connection) with the rigid brush 3 by means such as buckle connection, welding, bonding, etc., and at the same time, the flexi...

Embodiment 2

[0066] as attached Figure 5 As shown, a specific embodiment of the track grounding device, the track grounding device 10 is connected between the car body 6 and the friction disc 4, and is used to conduct the electrical connection between the car body 6 and the rail 8 to realize the grounding function. The grounding device 10 includes a flexible brush 1, and the flexible brush 1 further includes:

[0067] connected to the base 2 of the vehicle body 6;

[0068] And the electric brush wire 20 connected to the base 2, the electric brush wire 20 is in elastic contact with the friction disc 4.

[0069] The flexible brush 1 is in contact with the friction surface of the friction disc 4, and the brush wire 20 of the flexible brush 1 goes deep into the gap of the friction surface, forming several small capacitors between the brush wire 20 of the flexible brush 1 and the friction disc 4, By forming a high-frequency current channel in the contact area between the flexible brush 1 and...

Embodiment 3

[0075] On the basis of Embodiment 1, the rigid brush 3 further surrounds the outer side of the flexible brush 1 in a ring-shaped surrounding structure. For the more detailed technical solutions of the remaining parts, please refer to the corresponding description in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com