Manufacturing method of self-aligned metallic silicide with improved electric characteristics on contact surface

A technology of metal silicide and manufacturing method, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of rising resistance value, easy agglomeration of cobalt silicide, and high reaction consumption ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] As far as the known technology is concerned, during the fabrication of cobalt metal silicide, it is easy to produce self-generated or residual oxide or any impurity on the surface of the source / drain region, thereby causing cluster shrinkage and shallow junction leakage. The present invention proposes a preferred process step to improve the electrical characteristics of the junction between the self-aligned metal silicide and the source / drain region.

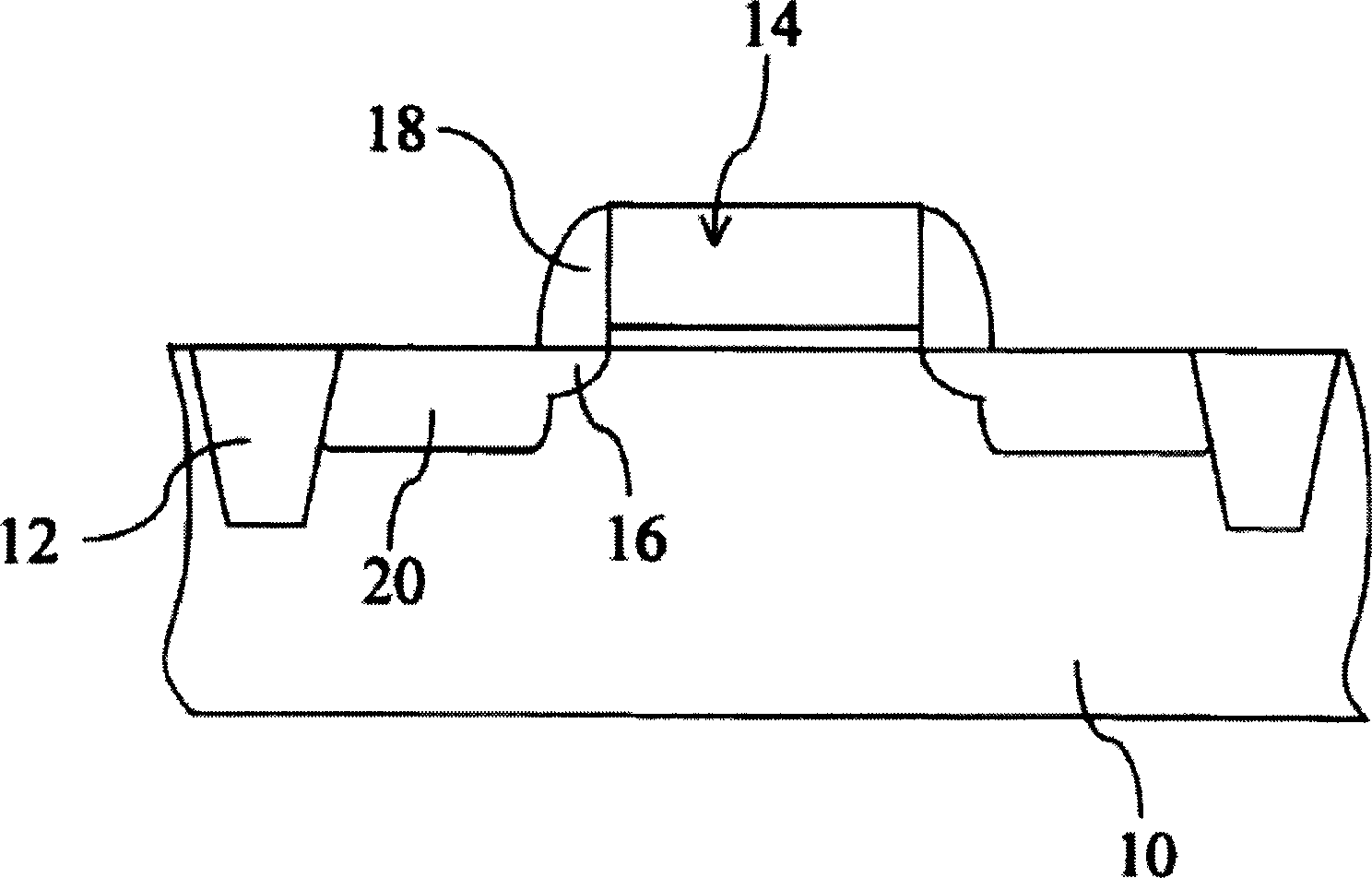

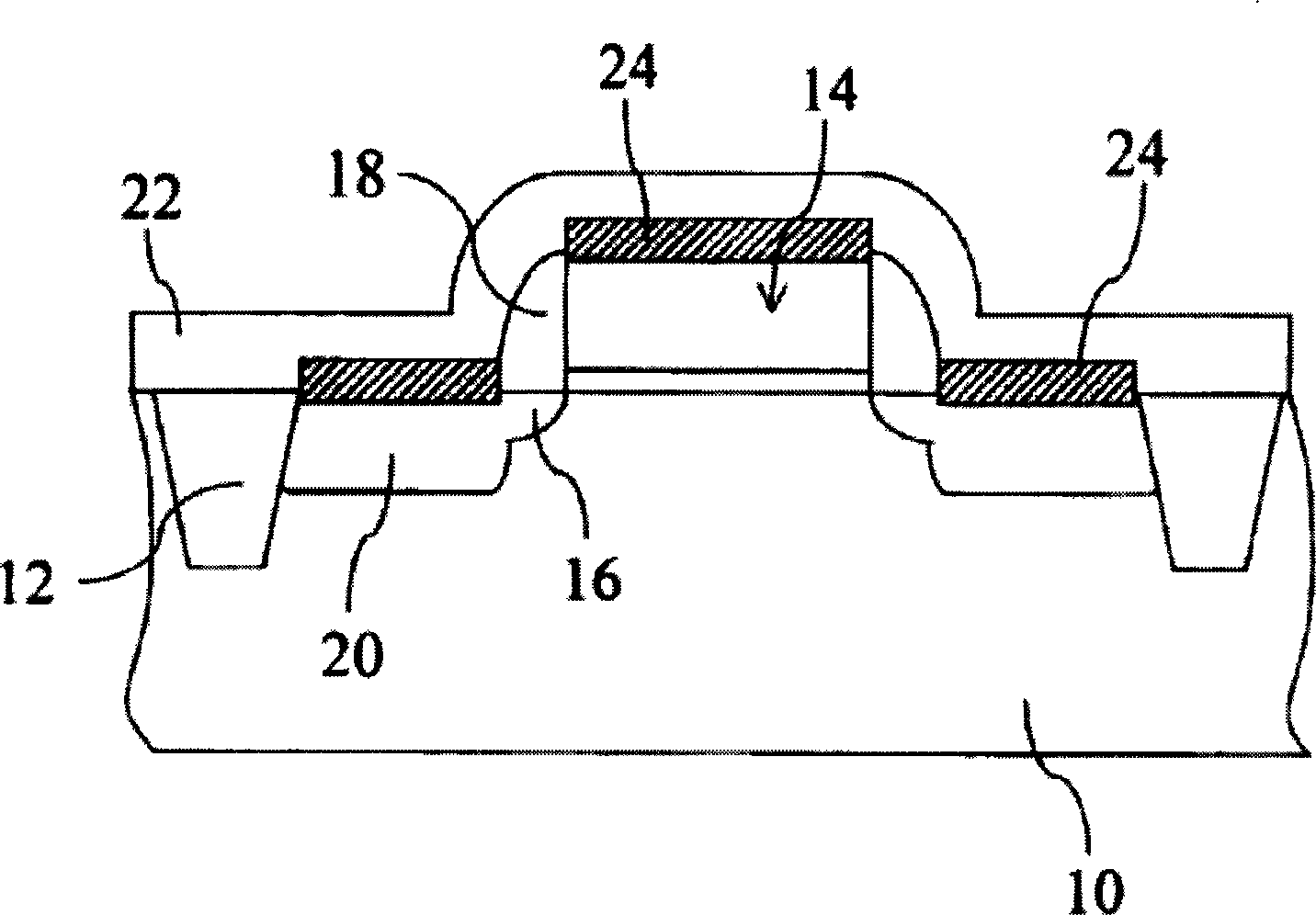

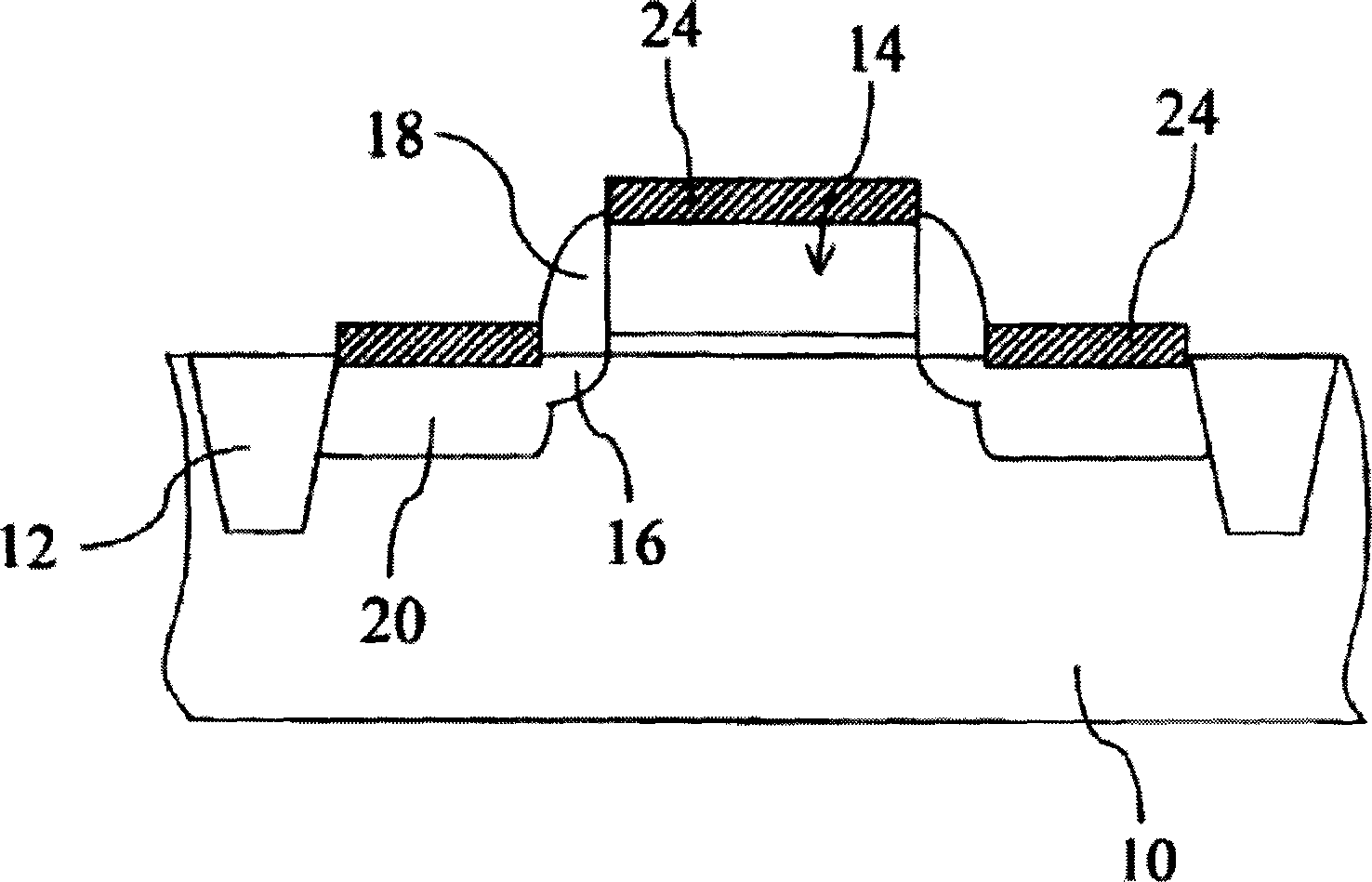

[0017] Figure 2(a) to Figure 2(d) It is a cross-sectional view of the structure of each step of making self-aligned metal silicide in the present invention. First, as shown in FIG. To isolate the active components and passive components in the semiconductor substrate 30; and then form a transistor gate structure 34 on the surface of the semiconductor substrate 30, which is composed of a gate oxide layer 342 on the surface of the semiconductor substrate and a polysilicon layer 344 above it; Then, using the gate structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com