Spade-type rotary cultivator

A rotary tiller and shovel-type technology, which is applied in the field of tillage machinery and equipment, can solve the problems of complex rotary tiller blade processing technology, potential safety hazards, and high rotational speed of the cutter shaft, and achieve the effects of compact structure, small motion cycle, and large transmission ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

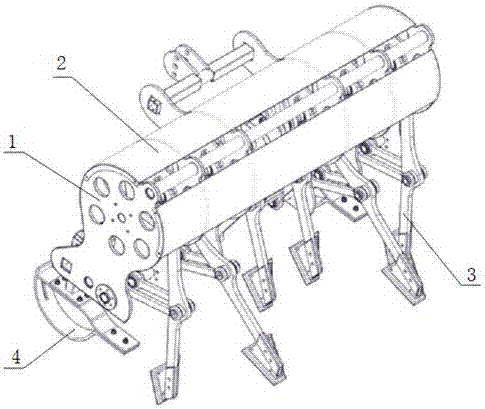

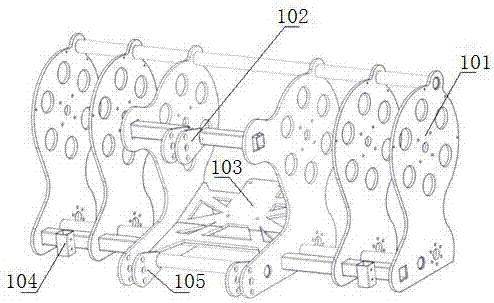

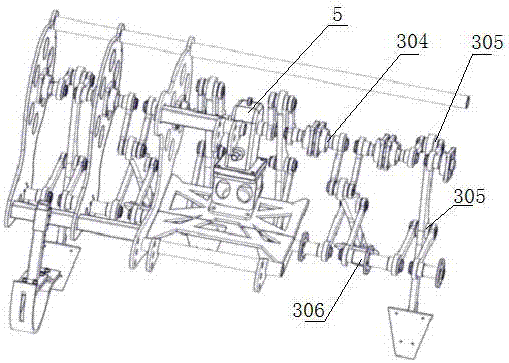

[0027] like Figure 1 to Figure 4 A shovel type rotary tiller is shown, which includes a frame welder 1, an array of actuators 3, and a reducer 5. The frame welder 1 includes a reducer connection welder 103, and the two sides of the reducer connection welder 103 There are three connecting plates 101 whose top ends are installed on the crossbeam symmetrically distributed, and the front and bottom ends of the two connecting plates 101 adjacent to the reducer connecting weld 103 are respectively provided with connecting support rods, and upper suspension welded joints are respectively installed on the connecting support rods. 102, lower suspension welding 105; both sides of each connecting plate 101 near the middle are connected with a group of actuators 3, and each group of actuators 3 includes a connecting rod assembly 301, a rocker assembly 302 and a crank as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com