Guide rail robot safety positioning system

A technology for safe positioning and robotics, applied in manipulators, manufacturing tools, etc., can solve problems such as prone to false detection, failure to detect external motor faults, and large detection errors, so as to prevent position conflicts, improve convenience, and prevent errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

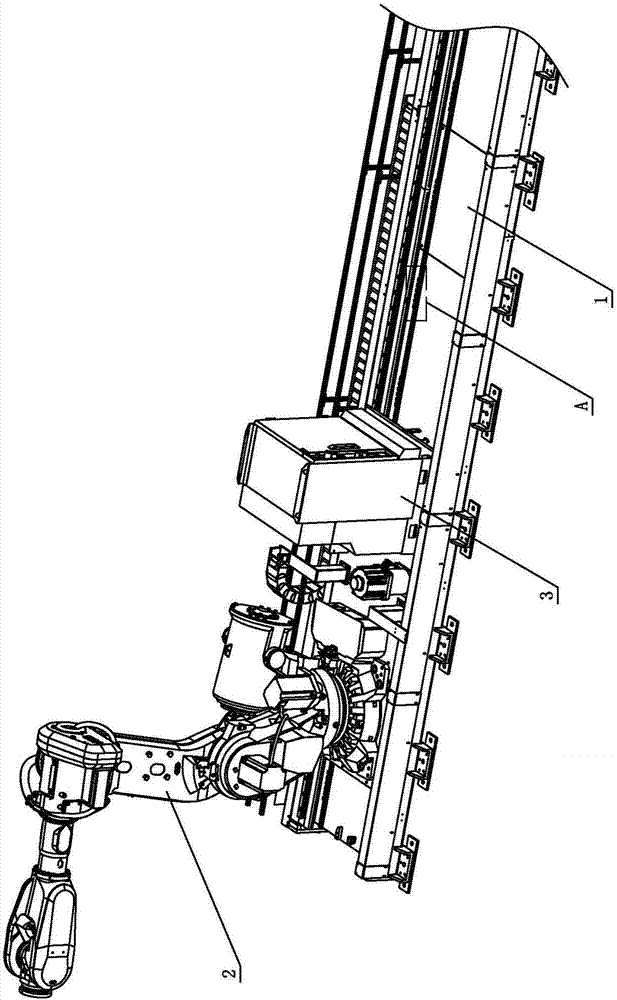

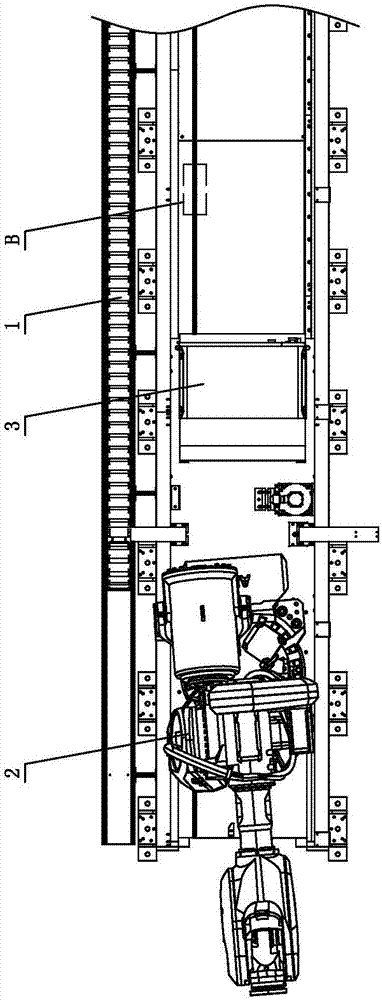

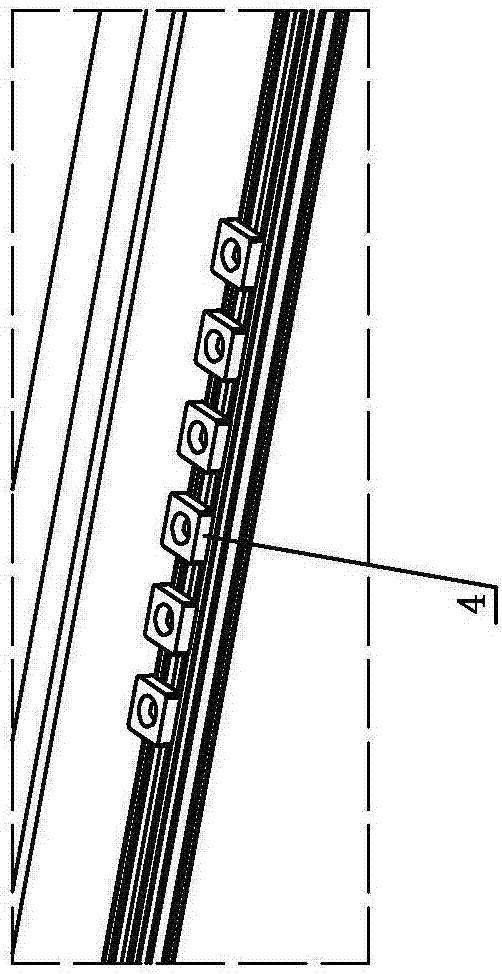

[0013] see Figure 1-Figure 5 , the guide rail robot safety positioning system, including the operation guide rail 1, the guide rail robot 2 and the electrical box 3, the bottom of the guide rail robot 2 and the electrical box 3 is provided with a sliding base, and the guide rail robot 2 and the electrical box 3 slide along the operation guide rail 1 through the sliding base The sliding base or the guide rail robot 2 is provided with sensors, and the working guide rail 1 is provided with more than one group of sensing components, each sensing component is linearly arranged along the working guide rail 1, and the sensor and the arrangement track of the sensing components correspond up and down; the sensing components are composed of More than one induction sheet 4 is formed.

[0014] An absolute motor is arranged on the sliding base and is driven by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com