Automatic packing machine counterweight wheel buffer device

A buffer device and counterweight wheel technology, applied in packaging, packaging machines, transportation and packaging, etc., can solve the problems of small contact area between the buffer and the counterweight wheel, easily damaged buffer anchor bolts, complicated replacement of the buffer device, etc. , to achieve the effect of preventing manufacturing difficulties, preventing impact, and preventing cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with embodiment the present invention is described in further detail:

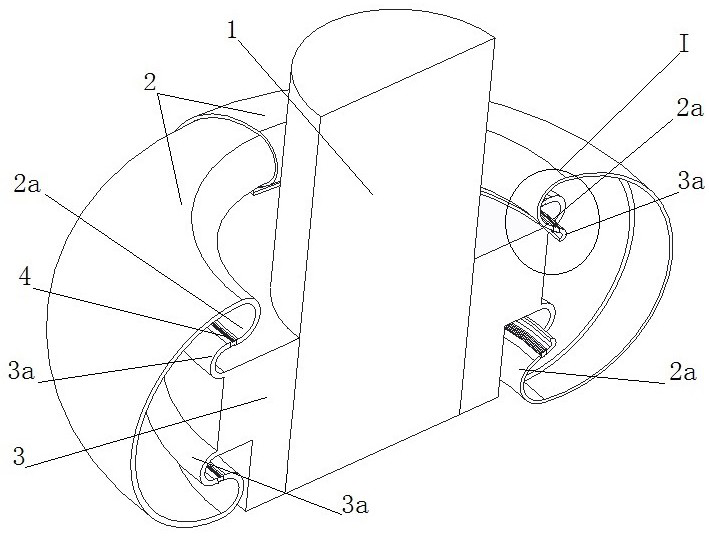

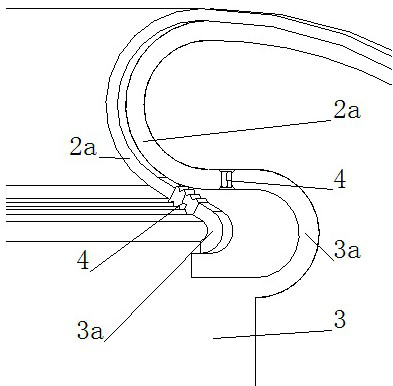

[0026] Such as figure 1 , figure 2 As shown, a counterweight wheel buffer device for an automatic baler includes a buffer platform 3, an anti-collision stone and a buffer tile 2, the buffer tile 2 and the buffer platform 3 are fixedly connected by a zipper 4, and the buffer platform 3 is sleeved on the counterweight roller skating Outside the road 1, the buffer platform 3 is cylindrical, and the buffer tile 2 wraps the buffer platform 3. The buffer tile 2 is fixedly connected to the outside of the buffer platform 3, and the buffer tile 2 is a tire-shaped soft structure, and the maximum height of the buffer tile 2 is greater than that of the buffer platform 3. The counterweight wheel directly hits the upper surface of the buffer tile 2. When the weight wheel falls along the weight wheel slideway 1, the impact kinetic energy is relatively large, and the buffer tile 2 below the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com