Novel fixture switching system

A switching system and fixture technology, applied to conveyors, storage devices, mechanical conveyors, etc., can solve problems such as high failure rate and long reaction time, and achieve high universality, save turning time, and save time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

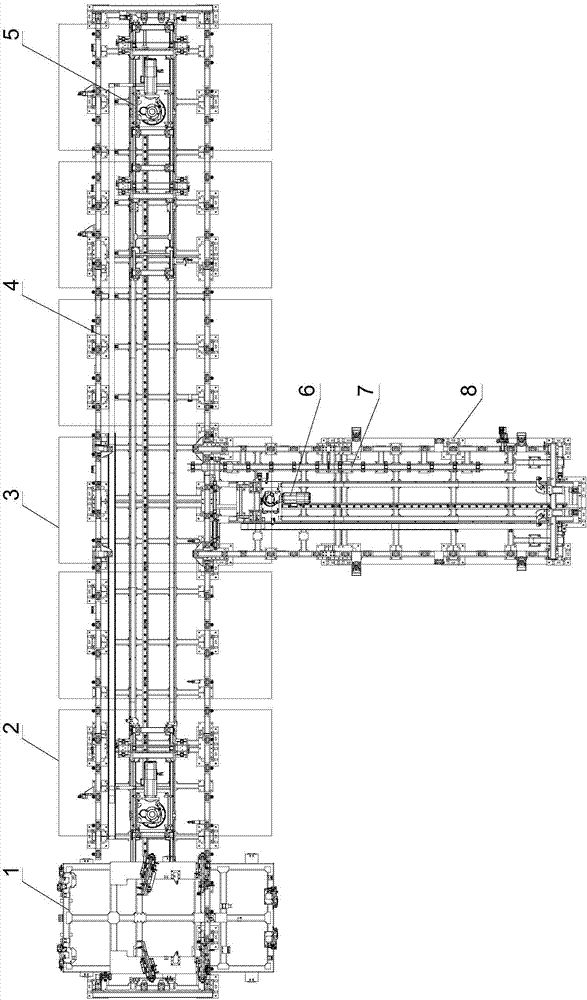

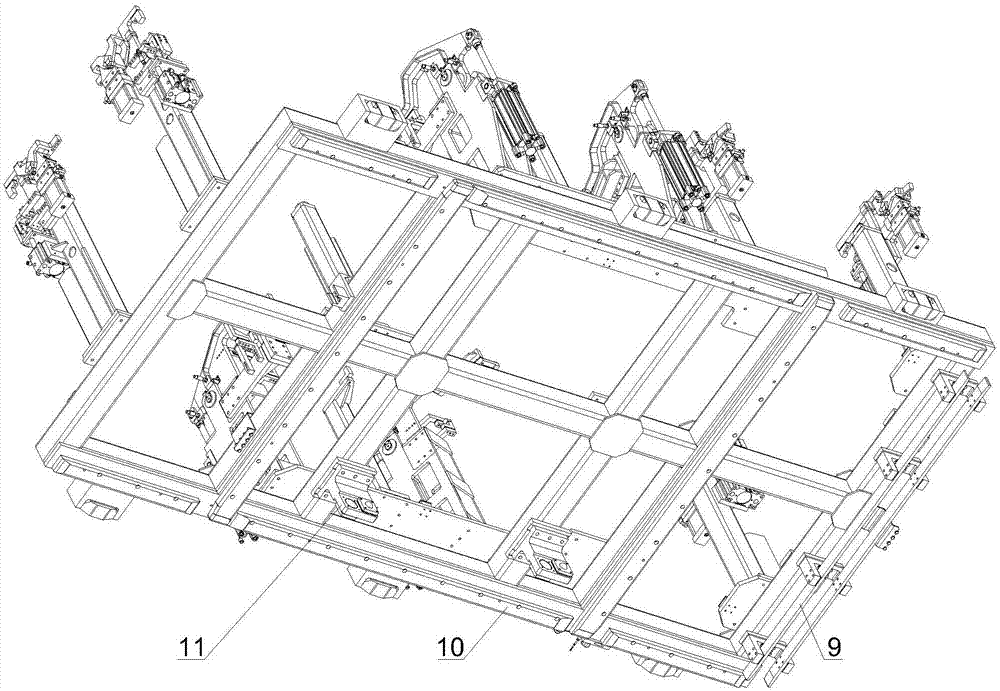

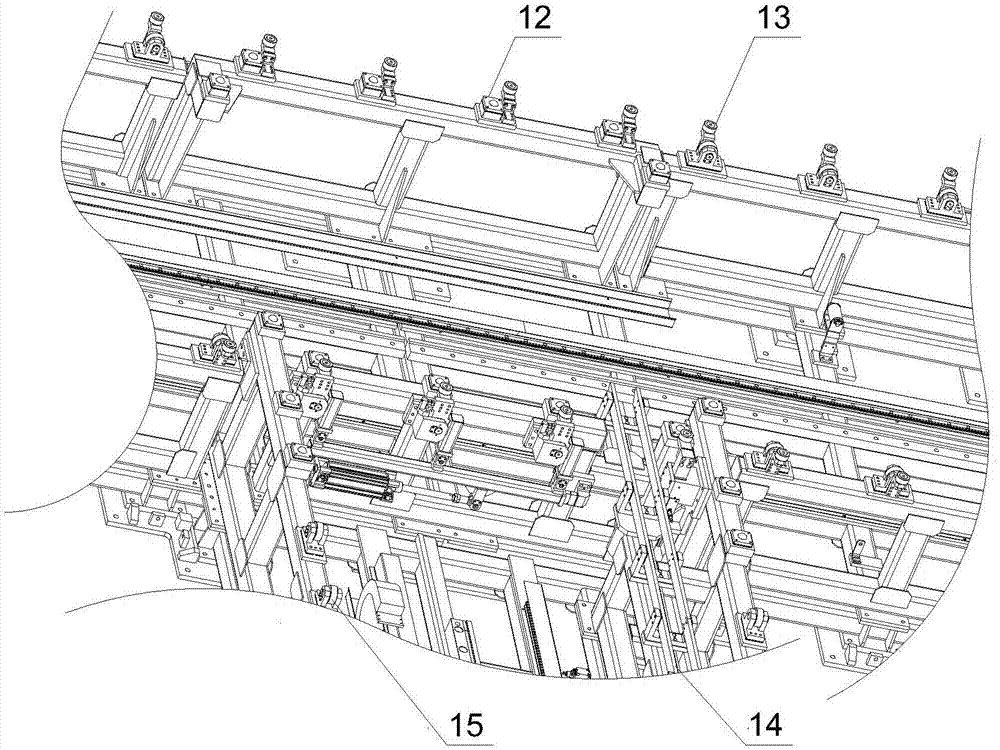

[0028] combine figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention includes an X-direction frame (4) and a Y-direction frame (7) installed on a horizontal plane, and the upper and lower sides of the X-direction frame (4) are respectively equipped with a fixture platform (1) and a fixture storehouse for conveying The trolley (5), the X-direction rack (4) are provided with a model switching warehouse (3) and multiple fixture storage positions (2) along the length direction, and the Y-direction rack (7) and the model switching warehouse (3) The X-direction frame (4) at the place is connected, and the Y-direction frame (7) is provided with a working position (8) corresponding to the vehicle type switching warehouse position (3) along the length direction, and the Y-direction frame (7) is installed with The work station conveying trolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com