A clothing automatic transmission and sorting system

A sorting system and automatic transmission technology, used in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as transmission and sorting contradictions, and achieve the goal of improving the degree of automation, reducing labor costs, and reducing the labor intensity of handling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

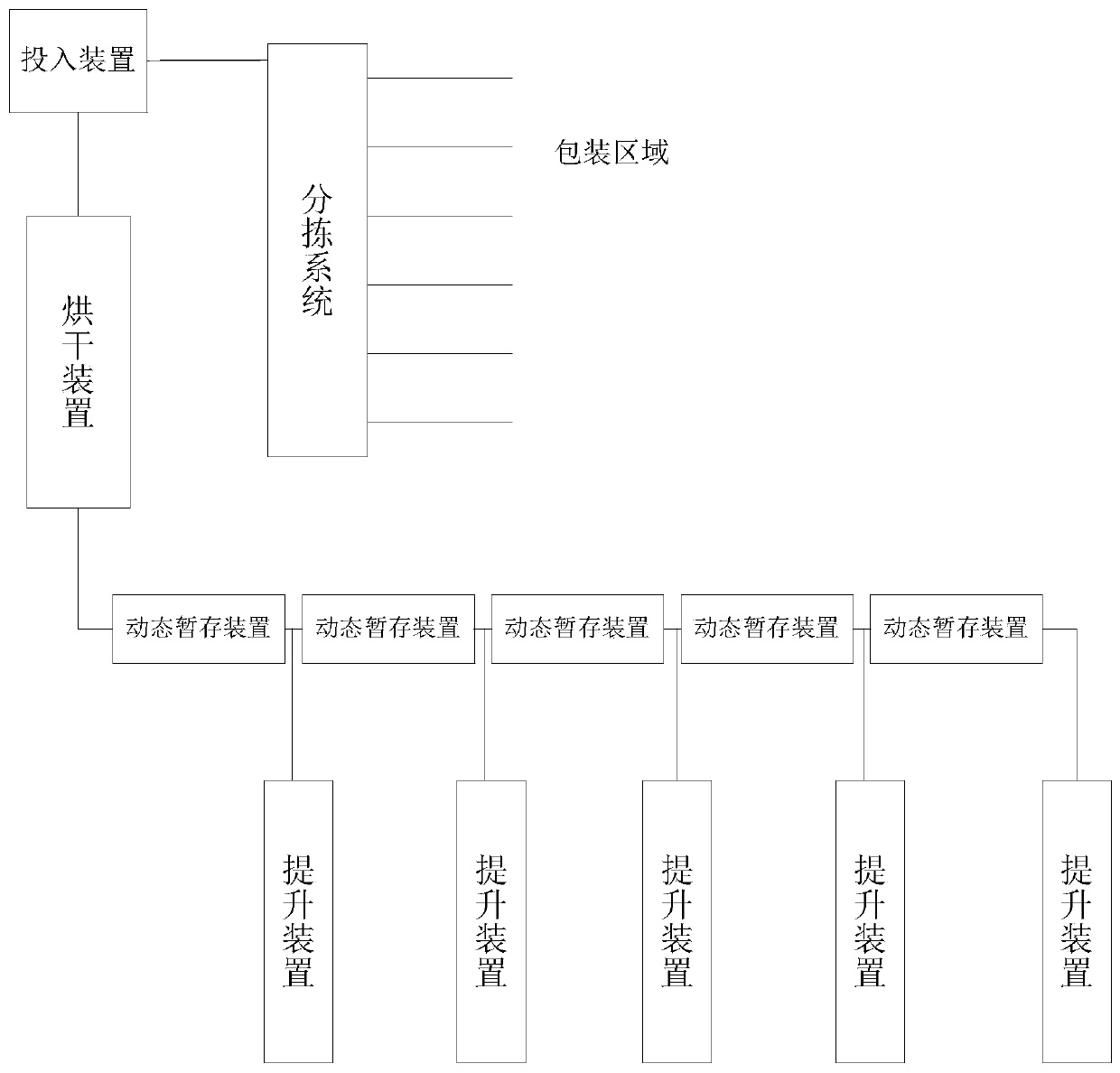

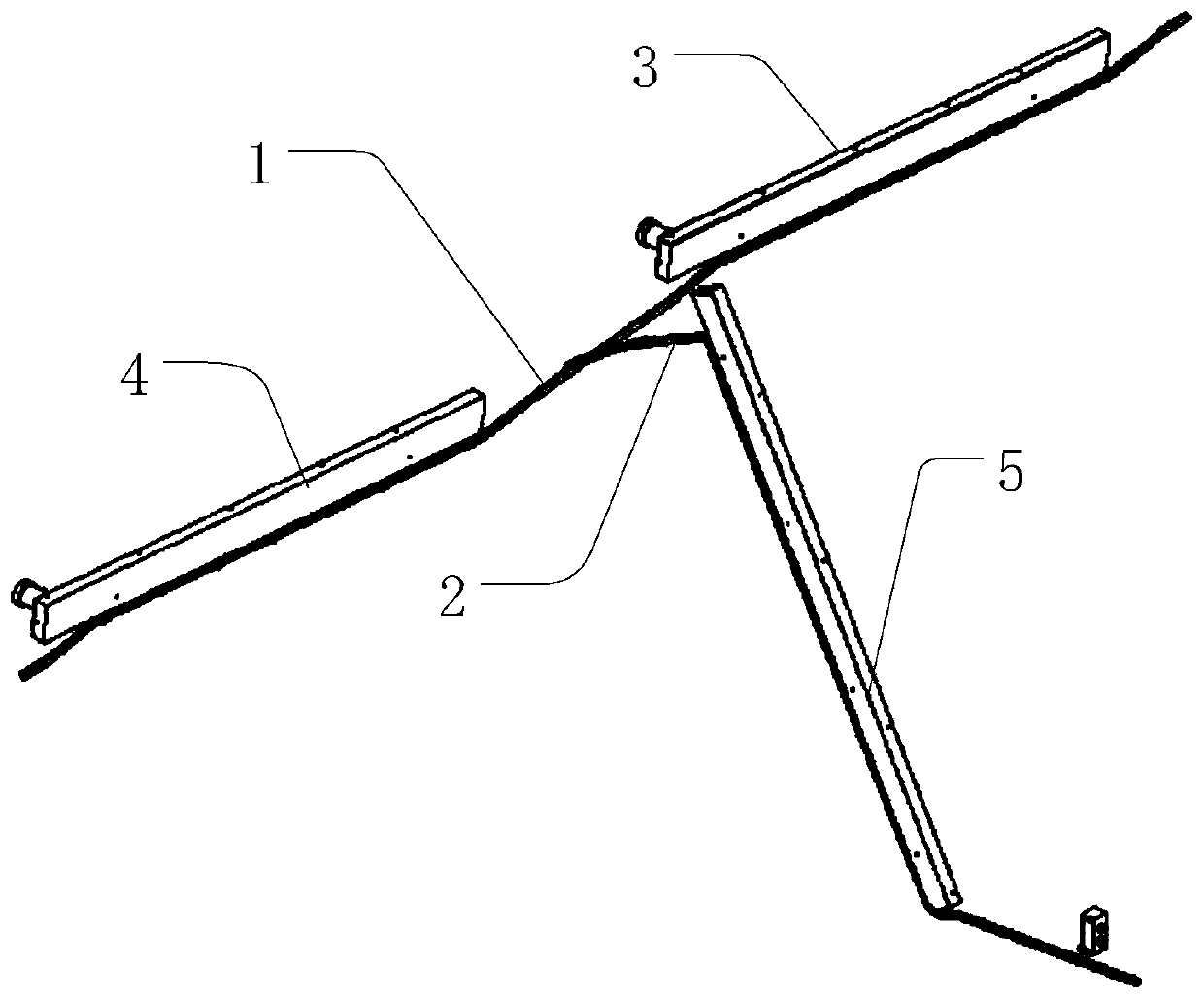

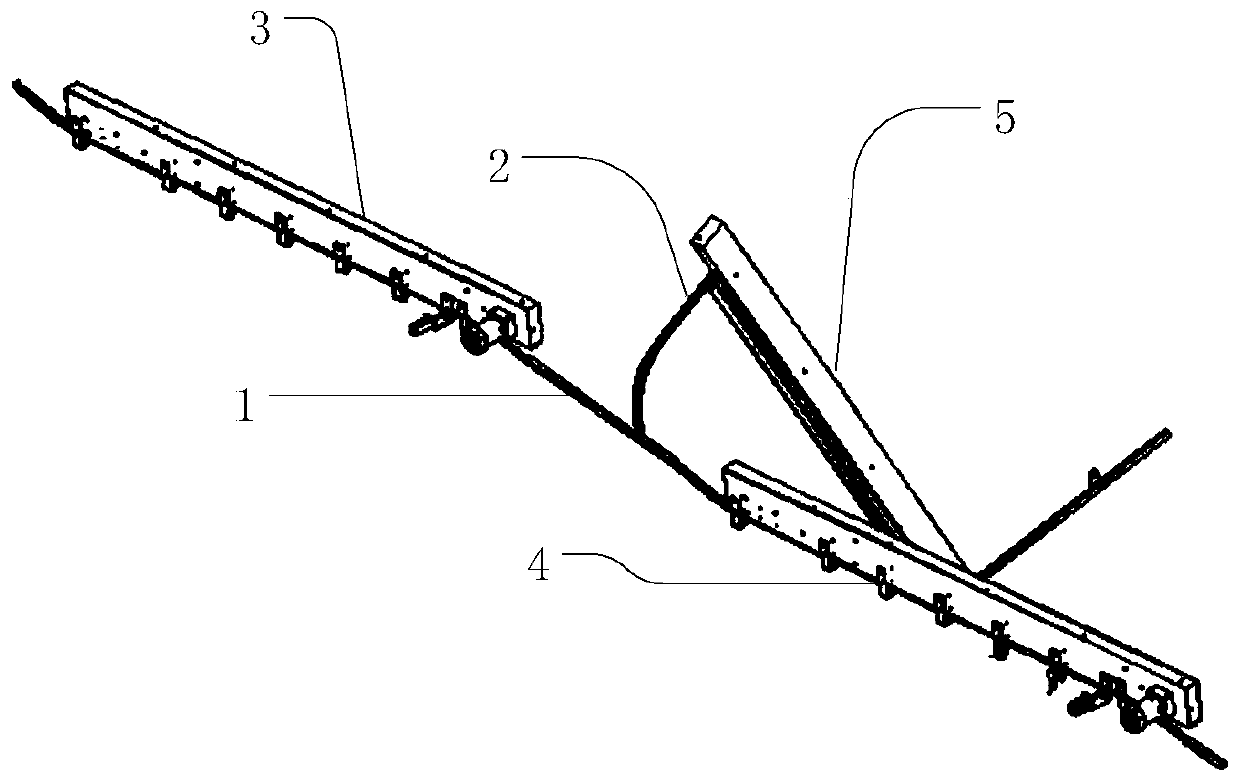

[0026] like figure 1 As shown, an automatic clothing transmission and sorting system, the system consists of a lifting device, a dynamic temporary storage and RFID identification system, a clothing input device, and a clothing sorting system. Clothes produced on each garment production line of the garment factory are put into the dynamic temporary storage through the lifting device, and the dynamic temporary storage transfers the clothes from one workstation to the next workstation, and finally sent to the input device. After the input device, the clothes will be put into To the clothes hook on the main rail chain of the sorting system, the sorting system is equipped with an RFID identification system, and the sorting system accurately distributes the clothes to the packaging production line according to the clothes information obtained by the RFID system.

[0027] The quality inspector on the clothing production line will check the quality and confirm that the qualified cloth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com