A kind of functionalized cellulose nanoparticle and its preparation method and application

A nanoparticle and cellulose technology, applied in the field of polymer chemistry, achieves the effect of broad application prospects, good thermal stability and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

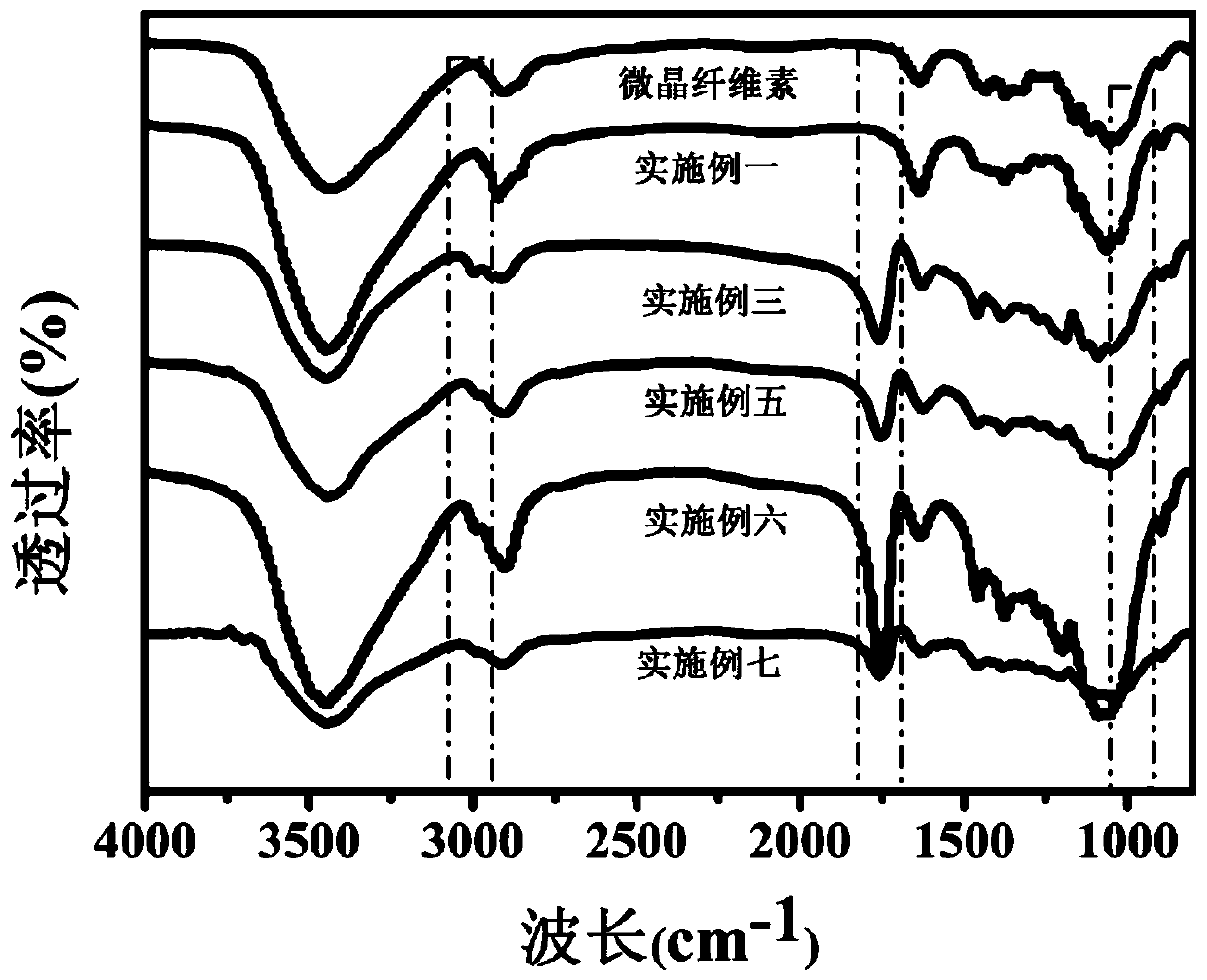

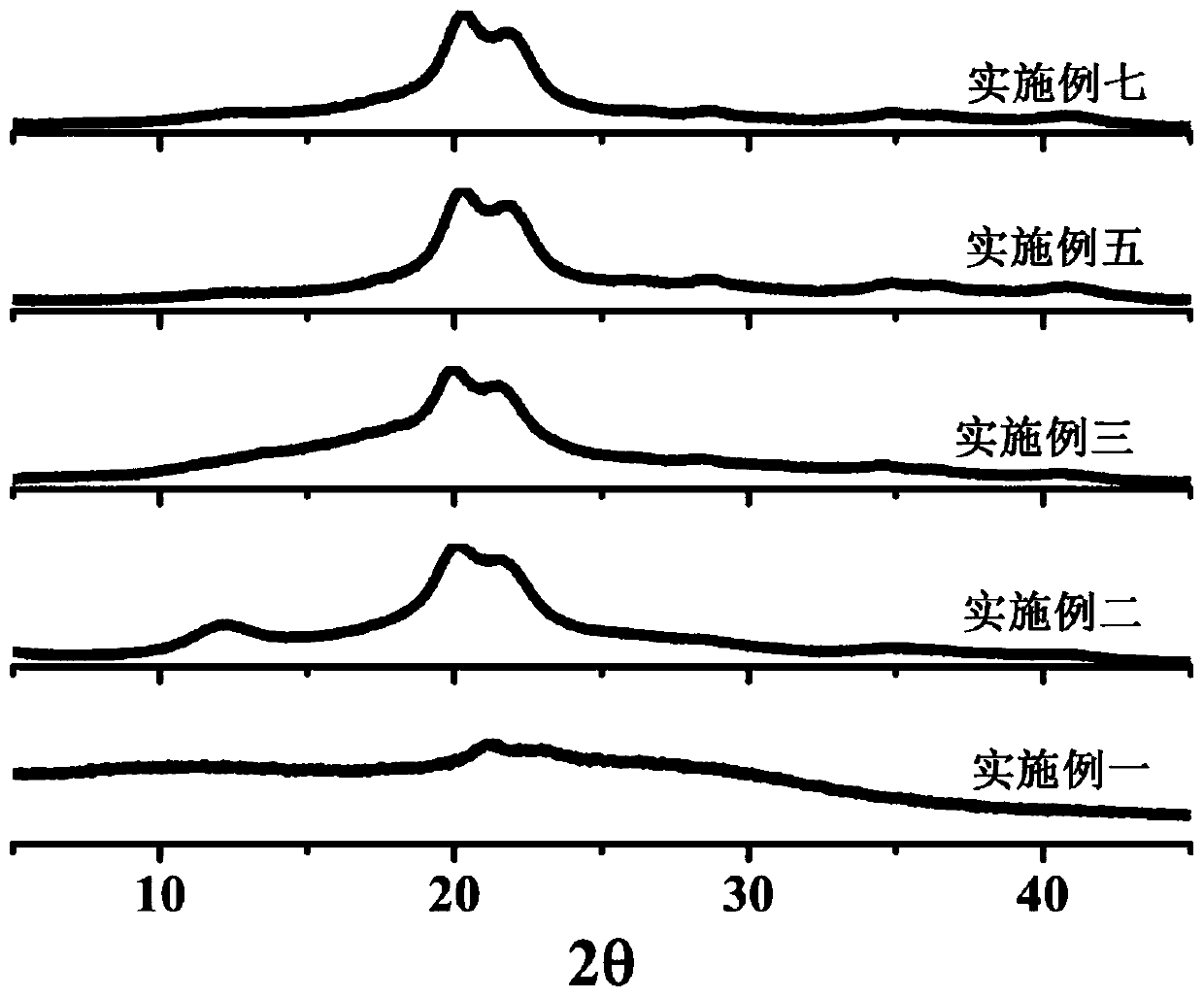

[0063] The invention provides a method for preparing functionalized cellulose nanoparticles, comprising the following steps:

[0064] 1) The regenerated cellulose hydrogel / aerogel with a three-dimensional network structure and the functional monomer lactic acid are stirred at 20-90°C for 0-48 hours under normal pressure, so that the functional monomer can fully penetrate into the regenerated cellulose water The inside of the gel / aerogel, so that the monomer and the regenerated cellulose hydrogel / aerogel are fully mixed (this step is to further improve the efficiency of its functional modification); wherein, the regenerated cellulose The cellulose content in the hydrogel / aerogel is 1wt% to 4wt% of the amount of functional monomers; in the present invention, the monomers used are capable of penetrating into the regenerated cellulose aerogel and the interior of the hydrogel , as much as possible in the liquid phase, thus avoiding the disadvantages of introducing organic solvents ...

Embodiment 1

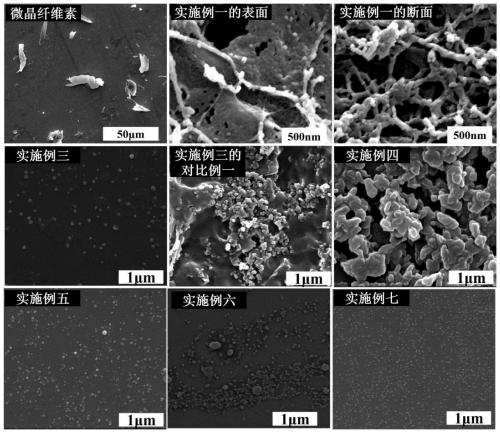

[0075] The preparation of embodiment one regenerated cellulose hydrogel

[0076] (1) Microcrystalline cellulose adopts the method for dissolving at low temperature to prepare a clear and transparent cellulose solution with a mass fraction of 4%;

[0077] (2) Take 2ml of the cellulose solution and add it to a 12-hole bacterial culture plate, and let it stand for 3 hours at a gel temperature of 60° C. to prepare a cellulose gel;

[0078] (3) Repeatedly soaking the obtained cellulose gel with deionized water until the aqueous solution becomes neutral to obtain regenerated cellulose hydrogel.

Embodiment 2

[0079] The preparation of embodiment two regenerated cellulose airgel

[0080] (1) Microcrystalline cellulose adopts the method for dissolving at low temperature to prepare a clear and transparent cellulose solution with a mass fraction of 4%;

[0081] (2) Take 2ml of the cellulose solution and add it to a 12-hole bacterial culture plate, and let it stand for 3 hours at a gel temperature of 60° C. to prepare a cellulose gel;

[0082] (3) Soak the obtained cellulose gel repeatedly with deionized water until the aqueous solution is neutral to obtain a regenerated cellulose hydrogel, and then place the obtained regenerated cellulose hydrogel in an environment of -170° C. for 1 to 2 minutes, Then put it in a freeze dryer for freeze-drying to obtain the regenerated cellulose airgel; the drying conditions are: 50Pa, -50°C, 12 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com