A plasma spraying process

A plasma and process technology, applied in metal material coating process, coating, melt spraying, etc., can solve the problems of power consumption, manpower and material resources, prolonging the production cycle, and affecting product performance, so as to save time and cost, improve Product quality, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0028] The plasma spraying process of the present embodiment comprises the following steps:

[0029] S1. Before spraying, place the sandblasted workpiece in the cleaning tank for cleaning, and use an air gun to dry the workpiece after cleaning. The purpose of cleaning is to effectively remove oil and other impurities on the surface of the workpiece, so that the subsequent sprayed coating will adhere more firmly and improve product quality. The specific cleaning method is: soak the workpiece in weak alkali solution at room temperature, and then take it out Rinse with pure water.

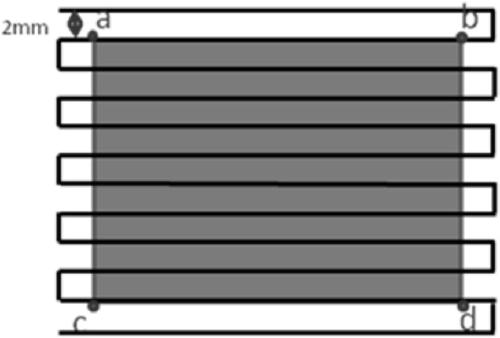

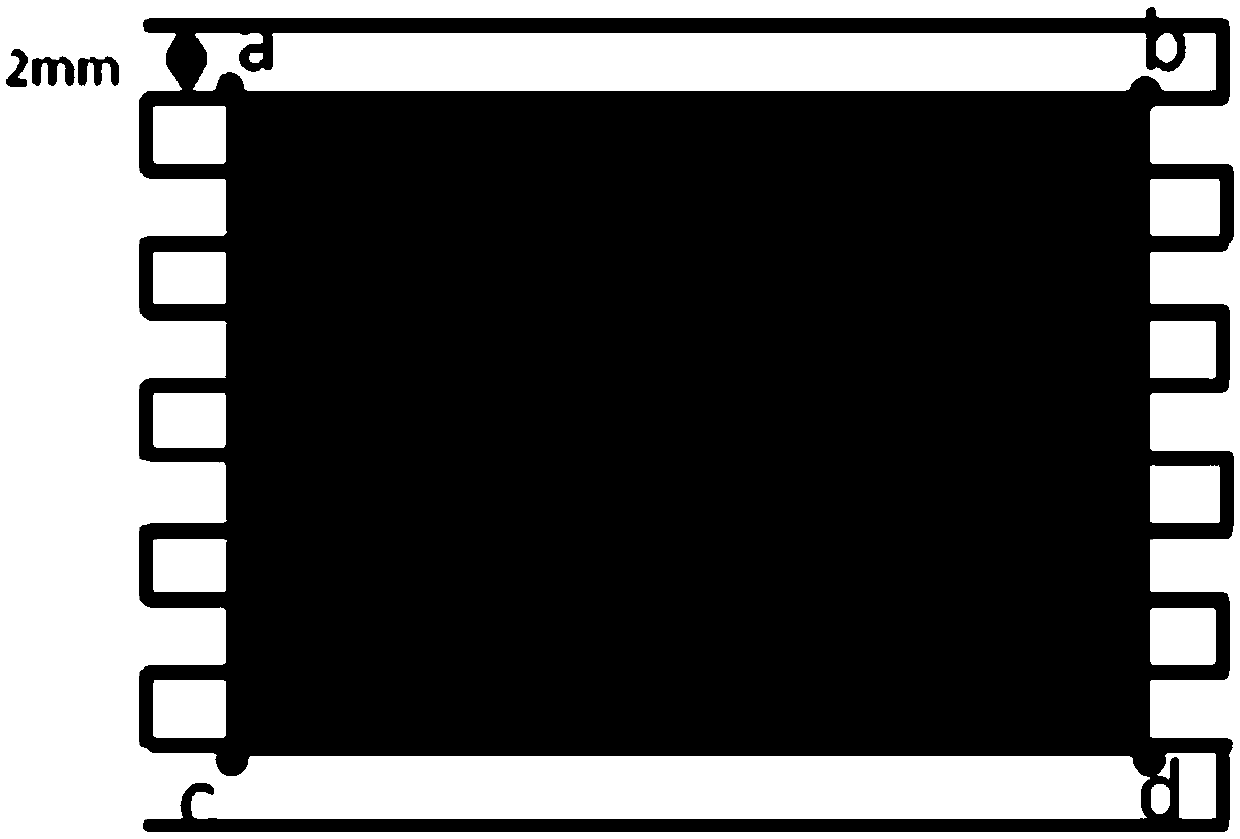

[0030] S2. Paste the spray tape on all the non-sprayed surfaces of the workpiece. It needs to be specially explained that the edge of the tape is 2mm away from the adjacent workpiece surface and the cut marks are neat. Use a scraper to scrape in the same directi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com