Cotton kneading method for quilt processing

A cotton quilt, a technology to be processed, applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve problems such as uneven thickness, and achieve the effect of uniform cotton thickness and uniform wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

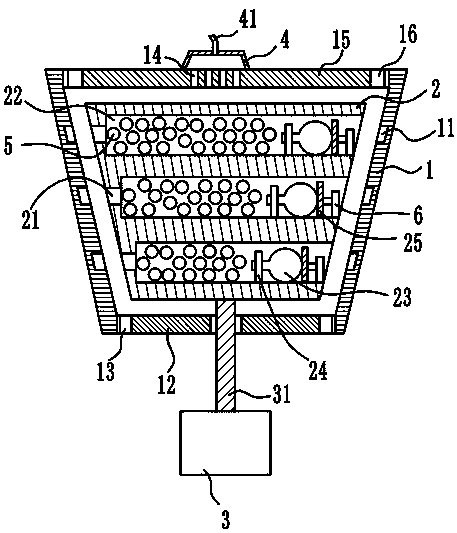

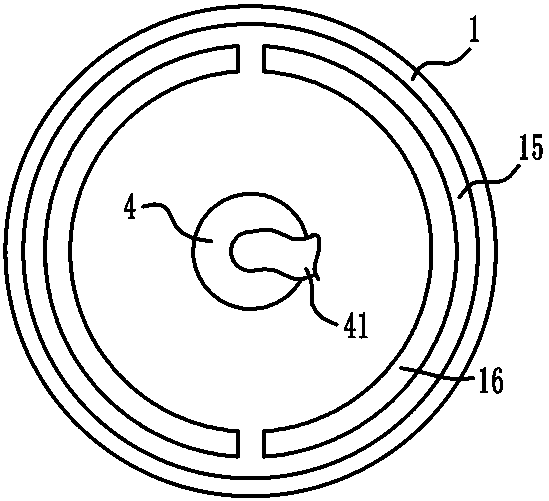

[0030] The present invention will be further described in detail through specific embodiments below.

[0031] The reference signs in the accompanying drawings of the description include: rubbing basin 1, rubbing body 2, drive plate 3, suction cup 4, cotton ball 5, telescopic cylinder 6, infrared receiving tube 11, bottom cover 12, second through hole 13, ash outlet Mouth 14, top cover 15, first through hole 16, cotton filling mouth 21, cotton storage cavity 22, air bag 23, support plate 24, push plate 25, rotating shaft 31, air pipe 41.

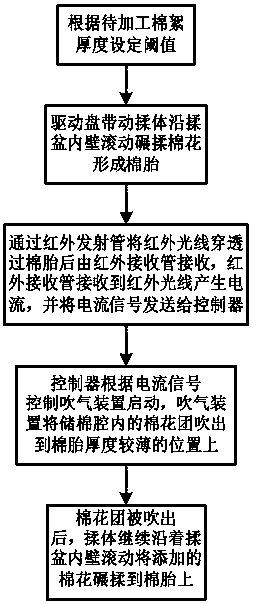

[0032] Cotton kneading method is used for quilt processing, such as figure 1 shown, including the following:

[0033] S1, first set the threshold according to the thickness of the cotton wool to be processed, and pass the infrared light emitted by the infrared emitting tube through the cotton wool sample to be processed, and the threshold is the current generated when the infrared receiving tube receives the infrared light penetrating throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com