A control method based on unilateral deceleration at the inflection point of industrial sewing patterns

A control method and sewing point technology, which is applied in the field of industrial sewing, can solve problems such as low sewing efficiency, inefficiency, and distortion, and achieve the effects of improving operating efficiency, improving sewing efficiency, and halving the amount of code

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

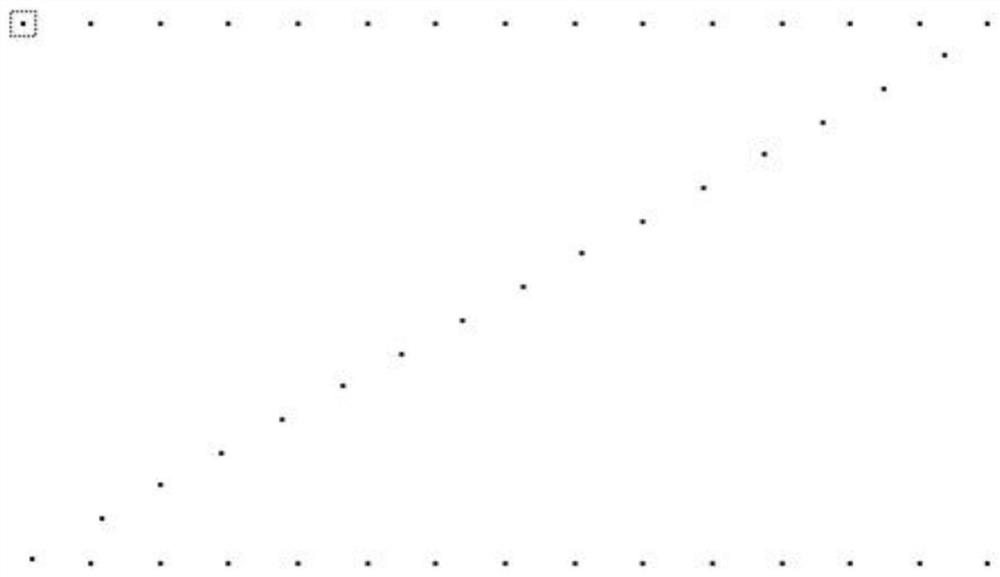

[0027] figure 1 It is the pattern diagram to be sewn in the embodiment of this application. First, use the pattern machine pattern making software to open the pattern diagram, and then generate the sewing points of the pattern to be sewn, such as figure 2 shown. Because this pattern has an inflection point, the pattern is likely to be distorted at the inflection point during the actual sewing process, and the inflection point deceleration must be set for it.

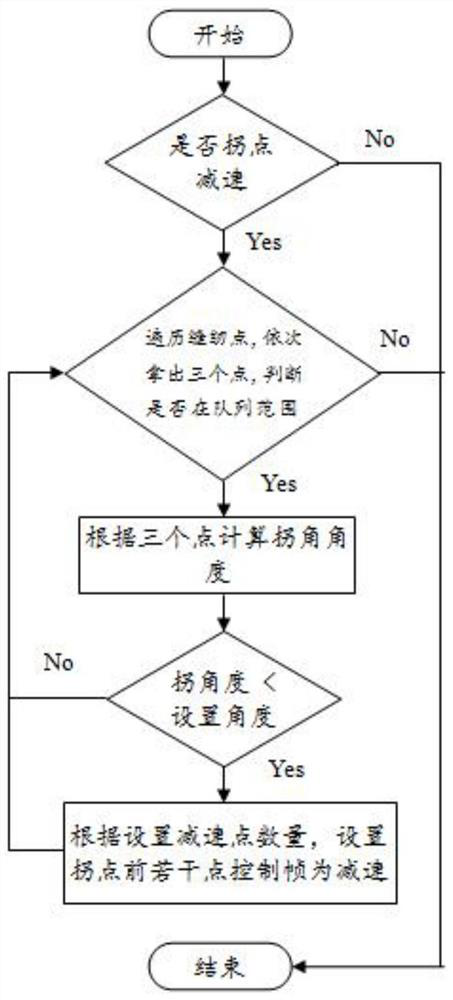

[0028] When generating the sewing points of the patterns to be sewed, we need to set the inflection point deceleration, set the number of deceleration points to 6 points, and set the angle to 100. The specific inflection point deceleration setting software implementation process is as follows image 3 As shown, in order to highlight the relative sewing point changes after the inflection point deceleration is set, such as Figure 4 As shown, the sewing points with serial numbers 10 to 15 are the deceleration points for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com