Curing process of mirror ink

A curing process, mirror ink technology, applied in the post-processing, printing and other directions of printing, can solve the problems of easy deformation of ink, low efficiency, product quality decline, etc., and achieve the effect of reducing pattern deformation, shortening time, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention. The present invention will be described in detail below in conjunction with the accompanying drawings.

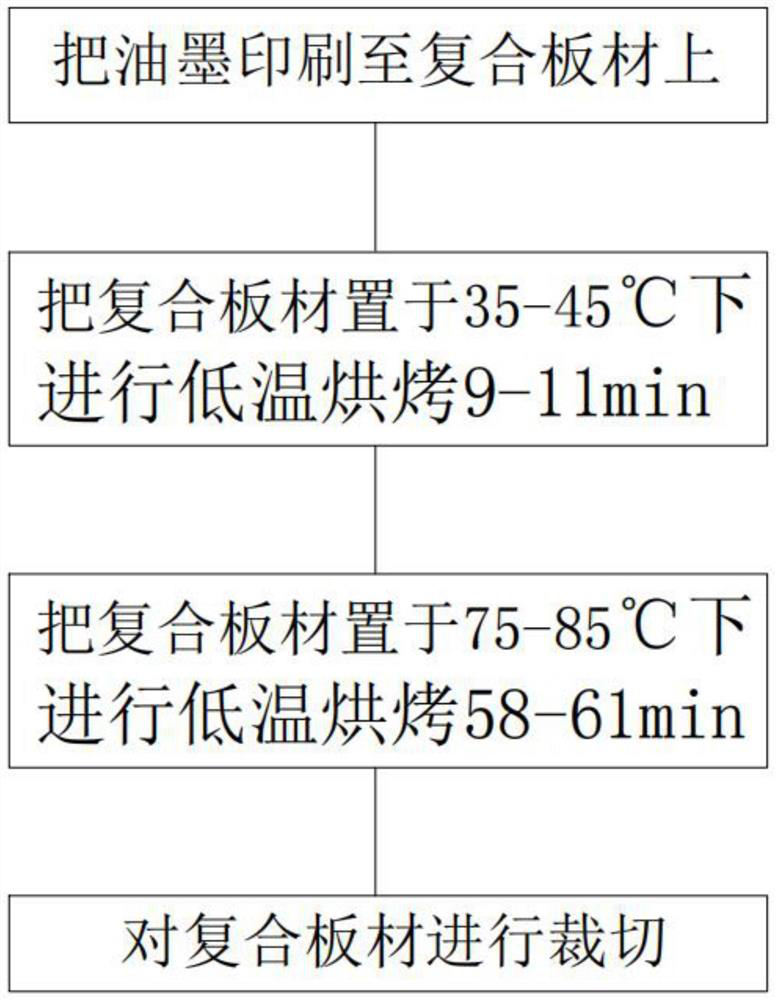

[0023] Such as figure 1 Shown, the curing process of a kind of specular ink provided by the invention comprises the following steps:

[0024] A. Print the ink onto the composite sheet;

[0025] B. Put the composite board at 35-45°C for low-temperature baking until the ink is set on the composite board;

[0026] C. Baking the composite plate after low temperature baking at high temperature, so that the ink is cured on the composite plate.

[0027] In the traditional natural air-drying method, it takes an hour or even longer for the ink to be printed and finalized, and if there is wind blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com