Lightweight soundproof masonry wall and construction method

A masonry wall, light-weight technique applied in the direction of walls, building components, buildings, etc., to achieve the effect of reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the embodiment of the present invention, the construction technical requirements such as steel structure welding and detailed structure treatment will not be repeated, and the embodiment of the present invention will be emphasized. The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The description is not limited to the following Example.

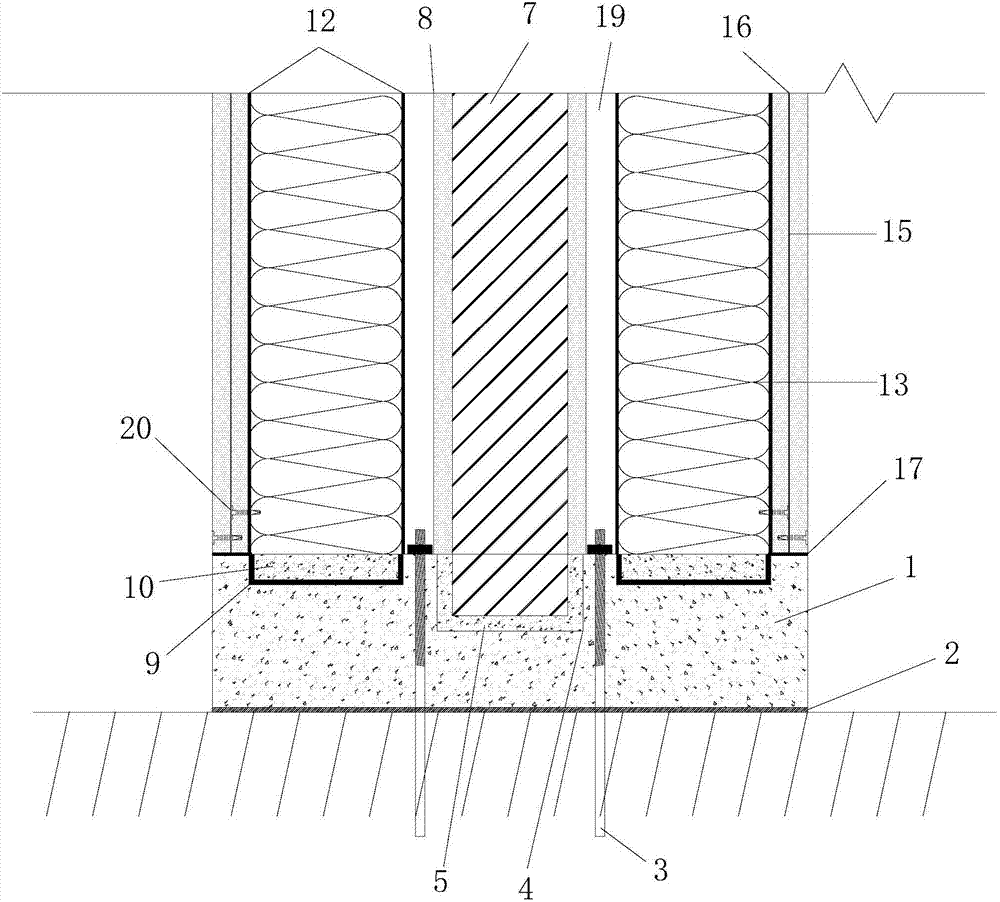

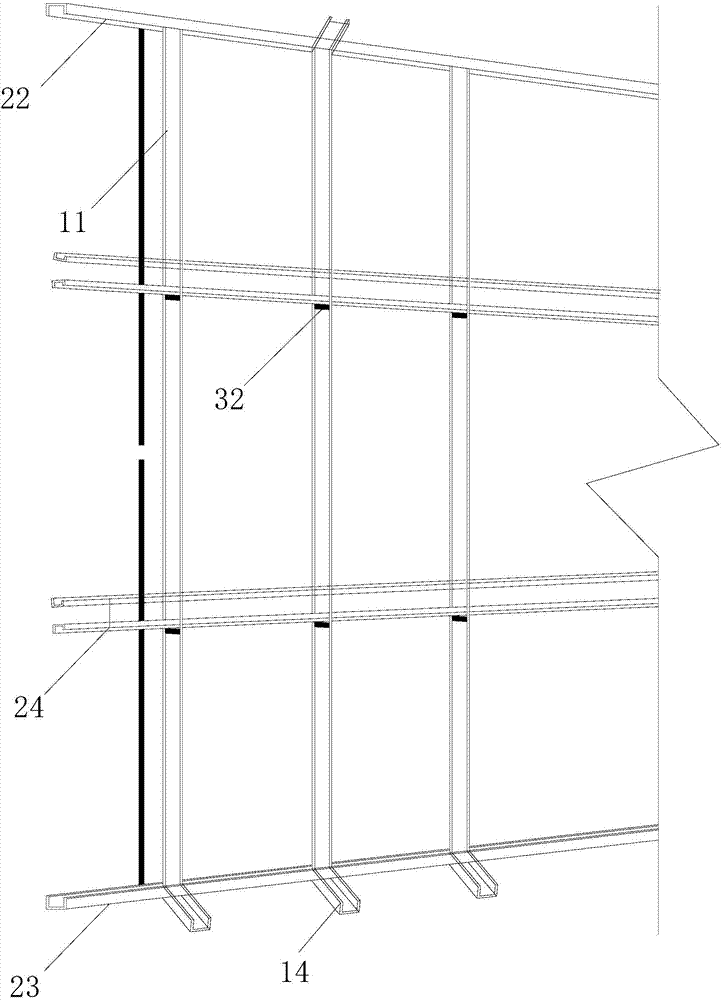

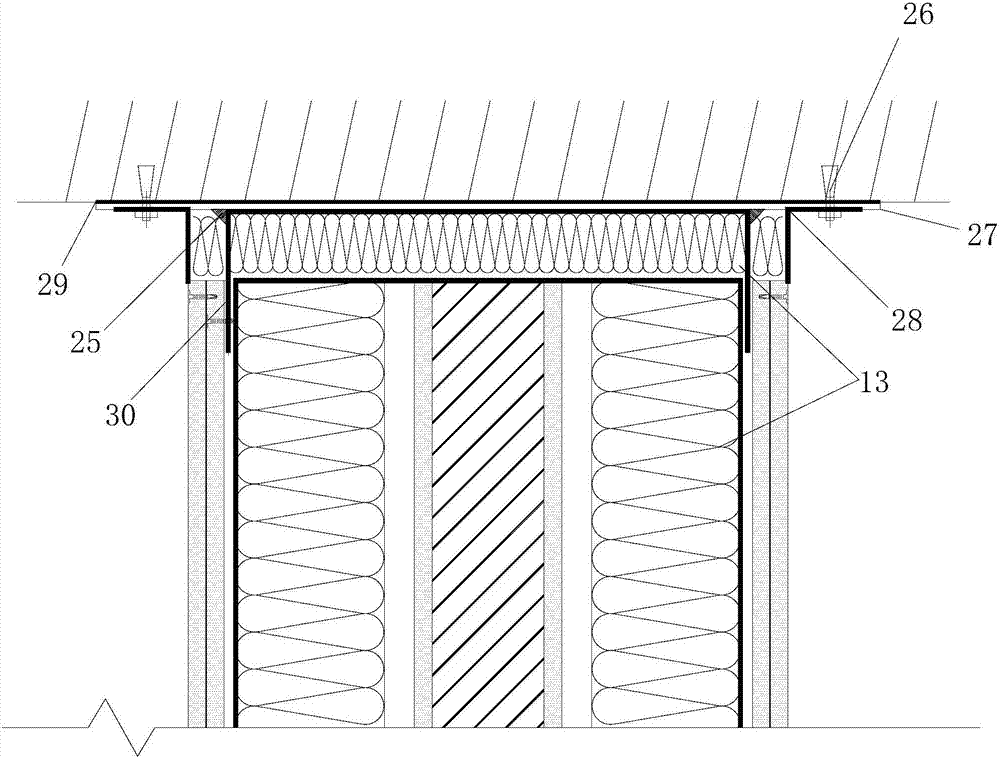

[0026] figure 1 is the cross-sectional view of the lightweight sound-insulating masonry wall, figure 2 It is a light steel skeleton diagram of a lightweight soundproof masonry wall, image 3 It is the top connection structure diagram of the lightweight sound-proof masonry wall, Figure 4 It is a joint treatment diagram of a lightweight soundproof masonry wall.

[0027] like figure 1 The light-weight sound-insulating masonry wall shown mainly includes light-weight block wall 7, single-layer gypsum board 8, grid reinforcement mesh 12, high-density filled ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com