Parking brake module for rail vehicle, brake cylinder and brake clamp unit

A technology for parking brakes and rail vehicles, applied in the direction of brake actuators, etc., can solve the problems of wear of the ring gear and pull pins, increase the movement resistance of manual sleeves, prolong the operation time of manual parking and ease, and achieve faster braking. The effect of automatic operation, shortening the space size, and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

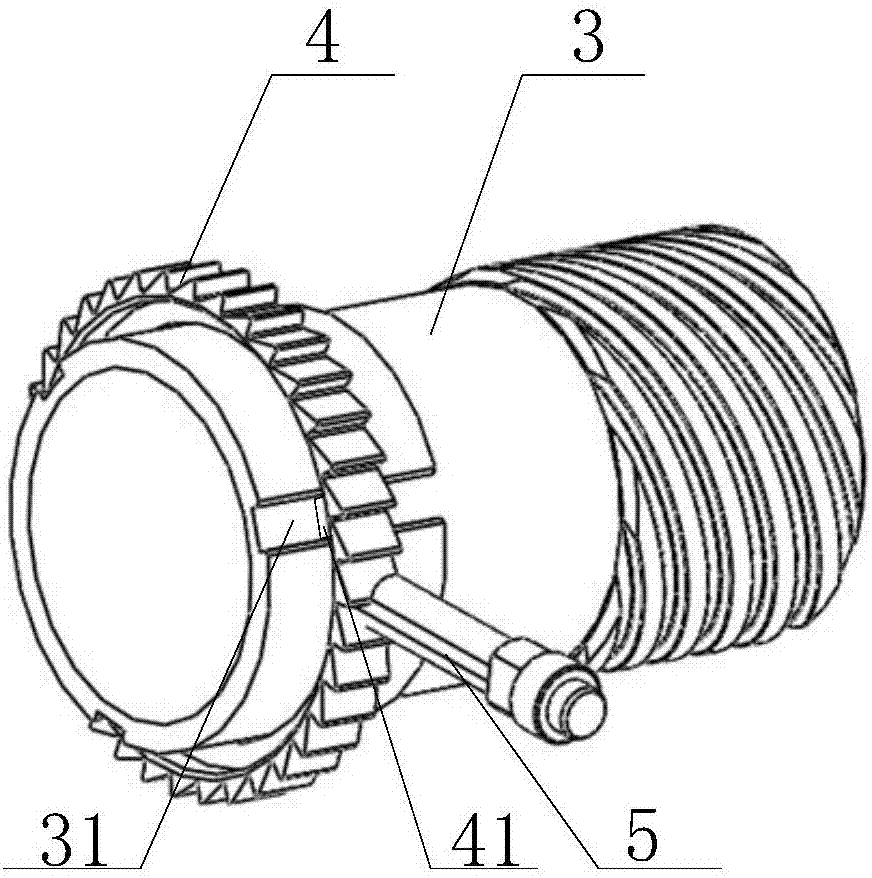

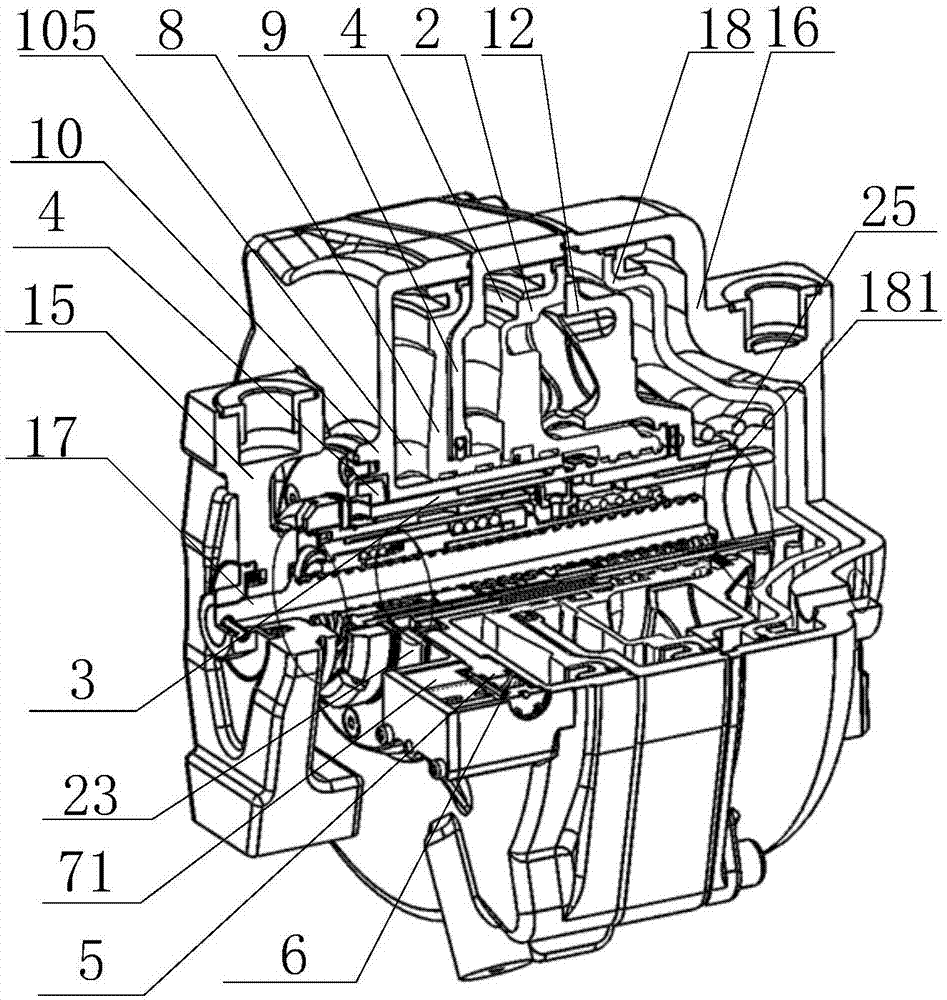

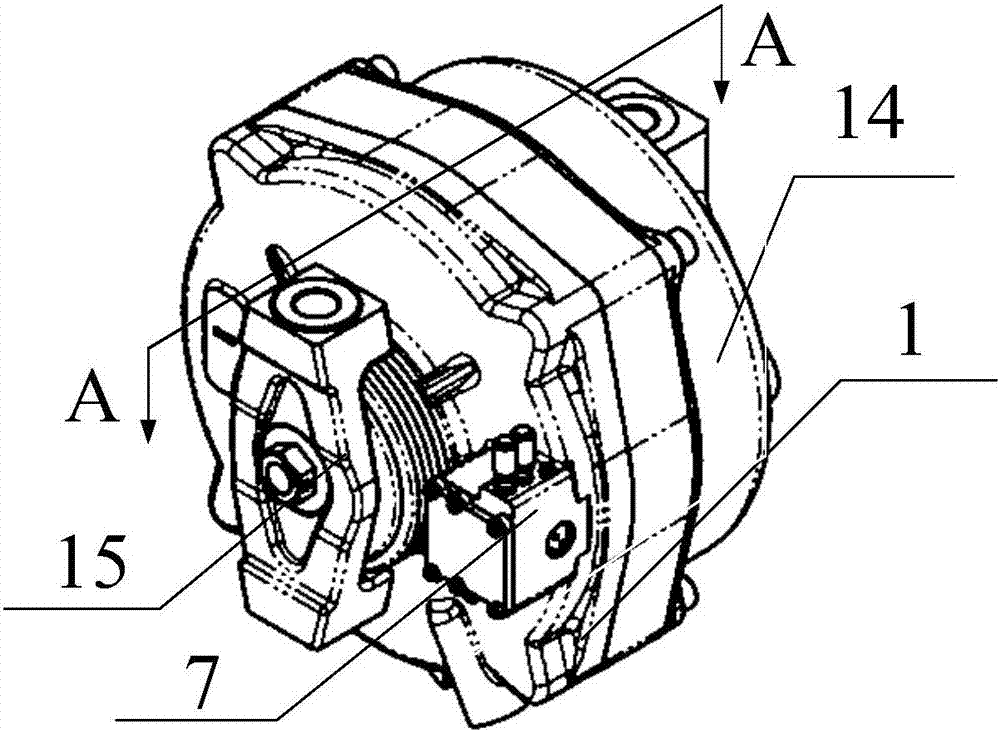

[0041] Such as figure 1 and figure 2 As shown, this embodiment provides a parking brake module 1 for rail vehicles, including a parking cylinder, a first parking piston 2 is arranged in the parking cylinder, and a hand brake is also arranged in the parking cylinder. The hand brake mechanism includes a parking rod 3, a runner 4 and a parking pin 5, the first parking piston 2 is fixedly connected to the parking rod 3, and the parking rod 3 is provided with a chute 31. On the inner wall of the runner 4, corresponding to the chute 31, there is a sliding piece 41 that is clamped on the parking rod 3, and the sliding piece 41 cooperates with the chute 32 to prevent the parking rod 3 from moving along its radial direction. sports.

[0042] The parking brake module of the specific embodiment above effectively avoids the abrasion between the parking lever and the running wheel, and the frictional resistance generated during the manual parking release operation is smaller, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com