Terminal wire threading device

A technology of threading device and terminal, applied in circuit/collector parts, electrical components, circuits, etc., can solve the problems of large wire feeding resistance, wire core bending, wire blocking, etc., and achieves simple structure, low cost, and easy operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

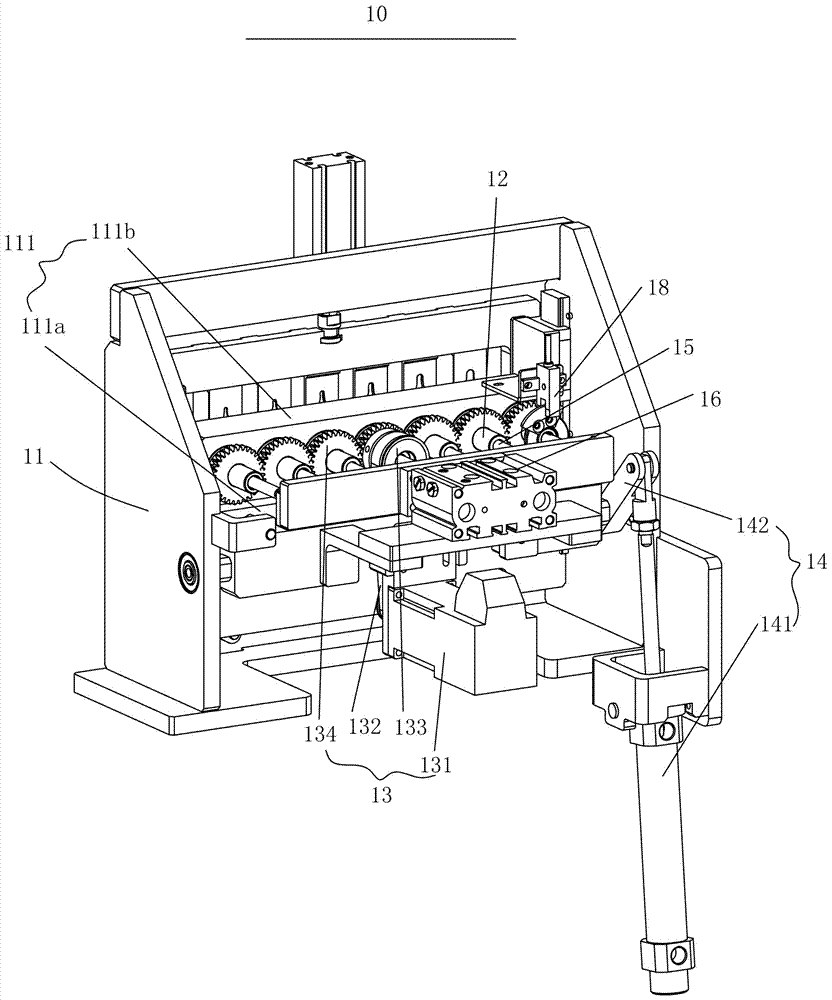

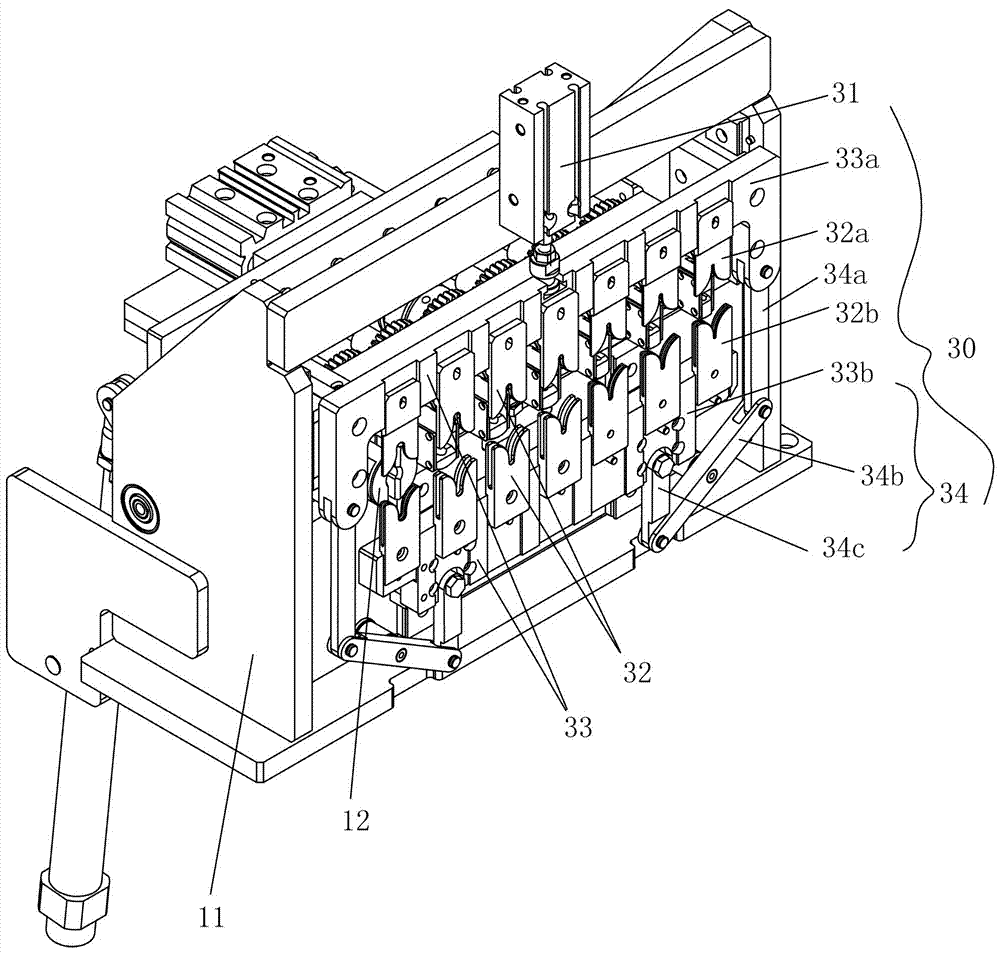

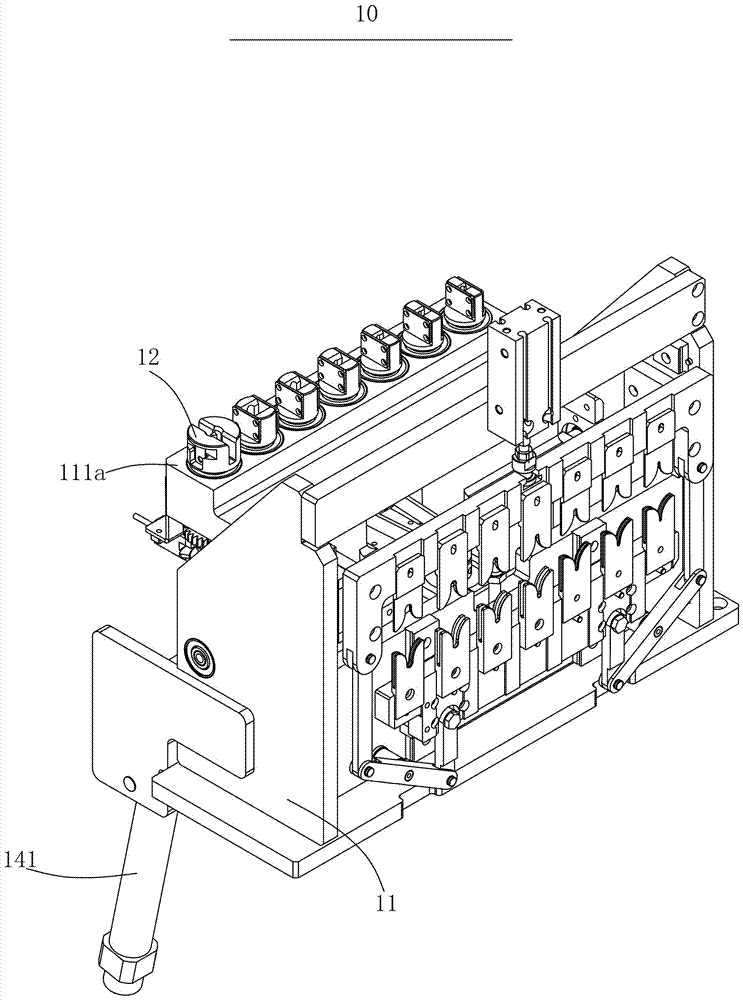

[0026] Such as figure 1 , figure 2 and Figure 5 As shown, the terminal threading device includes a wire harness feeding mechanism (existing equipment, not shown in each figure), a terminal fixing mechanism 10, a terminal 20 and a guide assembly 30. The terminal fixing mechanism 10 includes a support 11, a terminal seat 12, a rotating Drive 13 and turning mechanism 14.

[0027] The terminal base 12 is pivotally connected to the bracket 111 of the support 11 ; the head of the terminal base 12 is used to fix the terminal 20 , and the tail of the terminal base 12 is connected to the rotary drive 13 in transmission. In this embodiment, the number of terminal bases 12 is multiple, and multiple terminal bases 12 are pivotally connected to the bracket 111 horizontally; and the types of multiple terminal bases 12 are various, and each terminal base 12 corresponds to a type of terminal 20 threading stations. Specifically with Figure 5 Two of them are described in detail as examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com