Tea strip tidying machine

The technology of a tea strip organizer and rack is applied in the direction of tea processing before extraction, etc., which can solve the problems of inconvenient operation, burnt hands of operators, etc., and achieve the effects of convenient operation, low manufacturing cost, and preventing tea leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

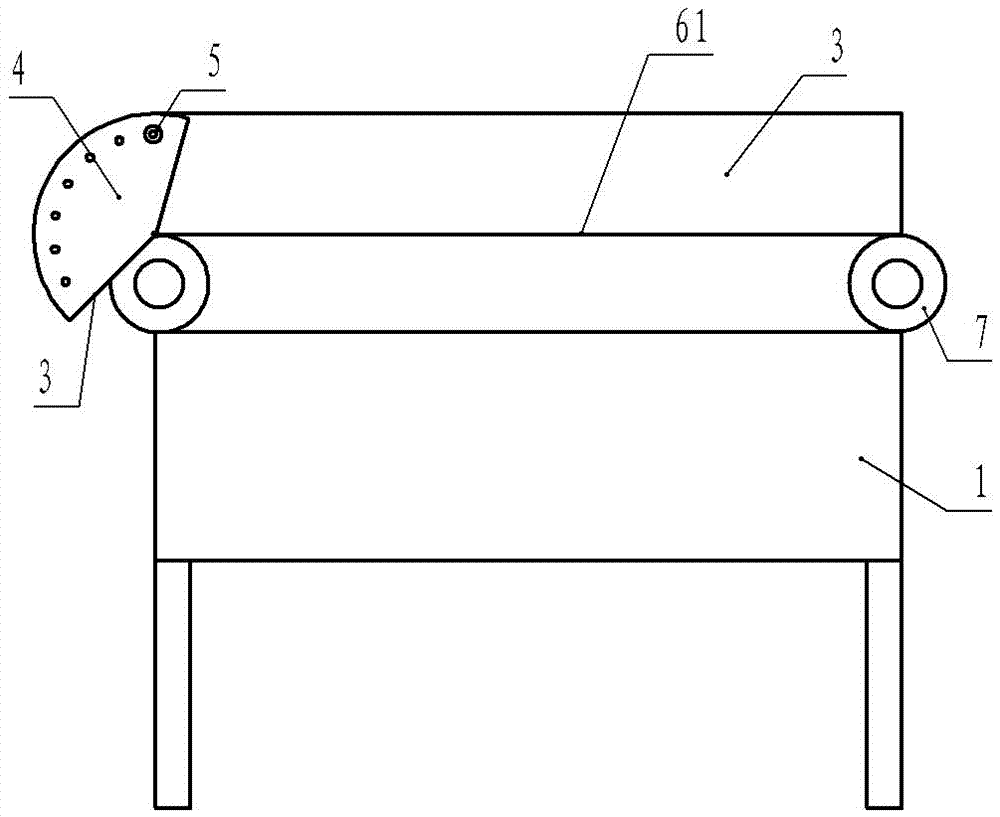

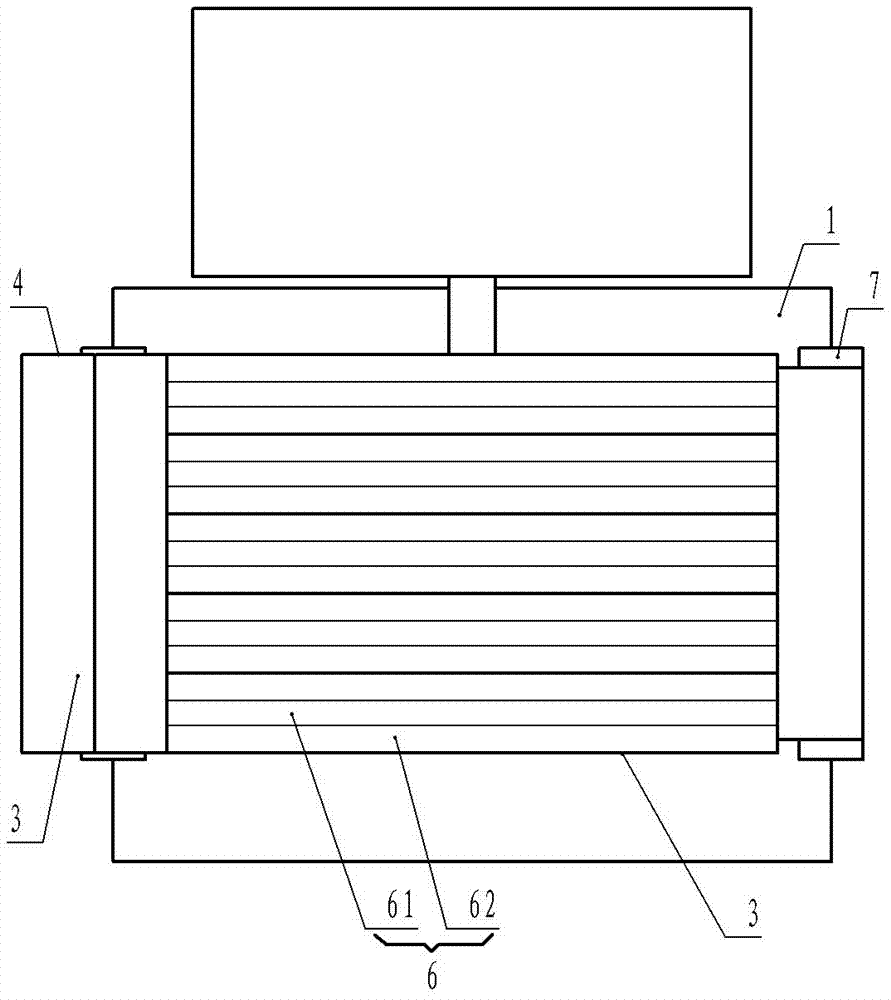

[0015] figure 1 , figure 2 The tea straightening machine shown includes a frame 1, on which a pot seat and a pot 6 arranged on the pot seat are installed, and the outer edge of the pot seat is provided with a baffle to protect the pot 6 3. The tank 6 is composed of a pot bottom 61 and a pot edge 62. The pot bottom 61 is an endless conveyor belt that runs towards the outlet of the tank 6 and is set on the frame 1 through the pulley 7. The upper side of the endless conveyor belt is connected with the pot The side 62 is tightly connected; the baffle plate 3 corresponding to the side of the pot seat at the exit of the pot 6 is hinged with the pot seat; the side baffles 3 have 2 mutually hinged; the two ends of the side baffle 3 are provided with There is a positioning block 4 for positioning the angle between the side baffle 3 and the horizontal; the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com