A kind of composite coal preparation flotation agent and preparation method thereof

A flotation agent and coal preparation technology, applied in flotation, solid separation, etc., can solve the problems that cannot meet the requirements of flotation production in coal preparation plants, the preparation process of composite flotation agents is complicated, and the collection performance is not strong. Achieve the effects of saving fossil energy consumption, excellent foam stabilization effect, and enhanced collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

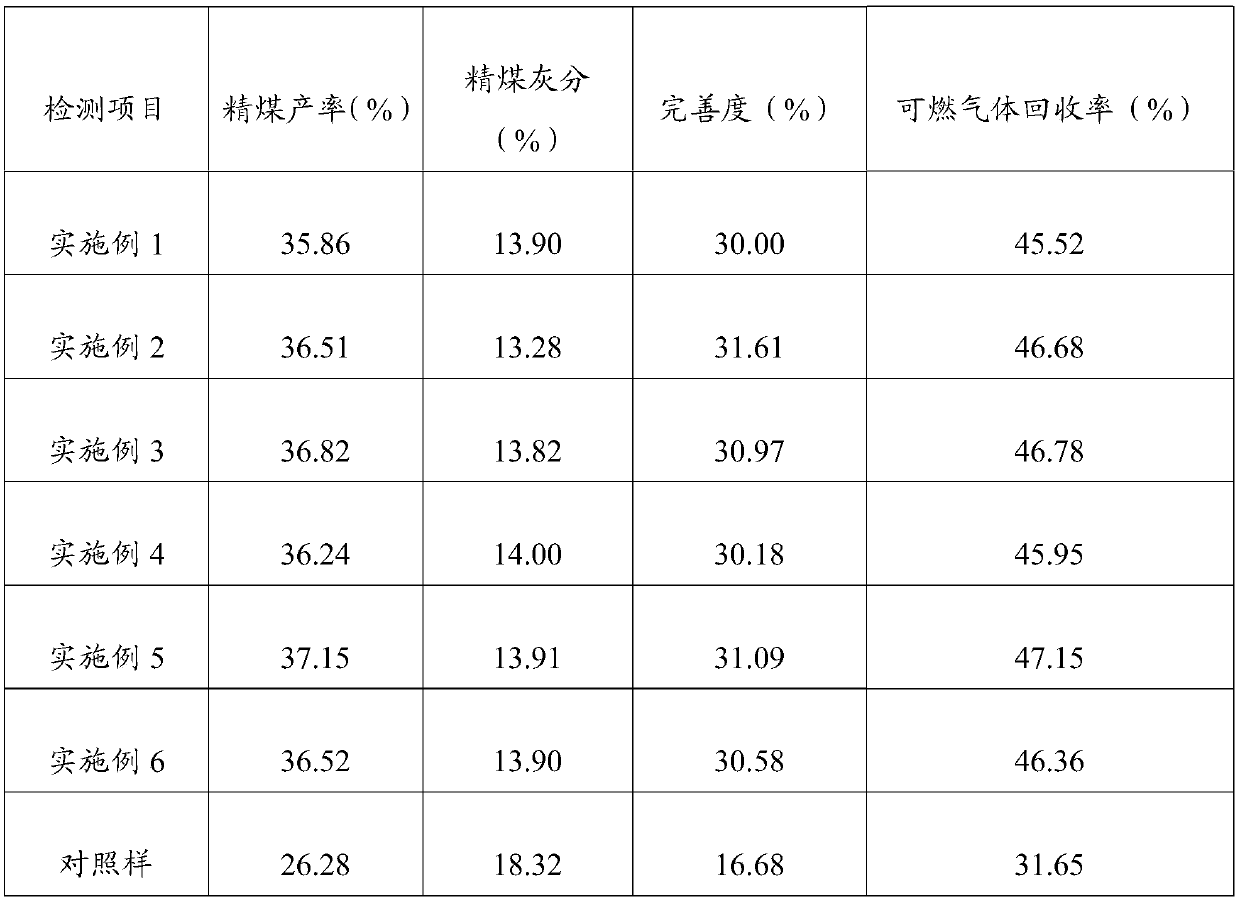

Examples

Embodiment 1

[0020] A compound coal preparation flotation agent, the preparation raw material is composed of the following components in parts by weight: 20 parts of kerosene, 15 parts of cotton oil fatty acid, 5 parts of N-chlorosuccinimide, hydrolyzed silk sodium lauroyl ester 1.5 parts, 0.15 parts of silicone resin polyether emulsion, 1.5 parts of octylphenol polyoxyethylene ether, 0.2 parts of benzamide, 42 parts of water.

[0021] Specifically follow the steps below:

[0022] Step 1, weigh 20 parts of kerosene, 15 parts of cotton oil fatty acid, 5 parts of N-chlorosuccinimide, 1.5 parts of hydrolyzed silk sodium lauroyl ester, 0.15 parts of silicone resin polyether emulsion, octylphenol polyoxyethylene 1.5 parts of ether, 0.2 parts of benzamide, 42 parts of water;

[0023] Step 2, mix the cotton oil fatty acid, N-chlorosuccinimide and benzamide weighed in step 1, and then heat and reflux at 80°C for 5 hours, and let it stand for 2 hours after the reaction to obtain the synthetic capt...

Embodiment 2

[0028] A compound coal preparation flotation agent, the preparation raw materials of which are composed of the following components in parts by weight: 25 parts of kerosene, 10 parts of cotton oil fatty acid, 3 parts of N-chlorosuccinimide, sodium lauroyl ester hydrolyzed silk 1 part, 0.1 part of silicone resin polyether emulsion, 2 parts of octylphenol polyoxyethylene ether, 0.1 part of benzamide, 40 parts of water.

[0029] The preparation method is the same as that of Example 1, except that the formula is changed into that of Example 2.

Embodiment 3

[0031] A composite coal preparation flotation agent, the preparation raw materials of which are composed of the following components in parts by weight: 30 parts of kerosene, 10 parts of cotton oil fatty acid, 2 parts of N-chlorosuccinimide, hydrolyzed silk sodium lauroyl ester 2 parts, 0.2 parts of silicone resin polyether emulsion, 1 part of octylphenol polyoxyethylene ether, 0.15 parts of benzamide, 45 parts of water.

[0032] The preparation method is the same as in Example 1, except that the formula is changed into that of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com