Inner groove machining device for lathe

A technology of processing device and inner groove, applied in metal processing equipment, tool holder, turning equipment, etc., can solve the problem of easy chattering, poor surface roughness of groove bottom, difficult control of groove radial size and axial positioning size And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

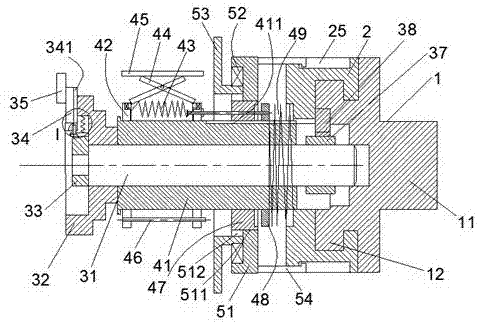

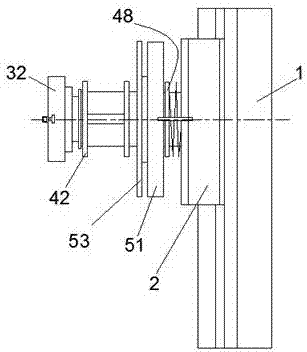

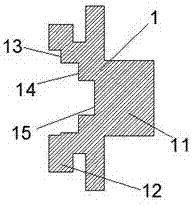

[0029] Such as Figure 1-Figure 8 As shown, an inner groove processing device for a lathe according to the present invention includes a clamping part 1, a body 2, a groove depth control device, an axial positioning size control device and a clamping device. The clamping part 1 is left There is a long rectangular convex strip 11 on the side, a rectangular guide rail convex strip 12 in the front and rear directions is provided on the upper and lower surfaces of the right side, and a front and rear direction is provided in the middle part of the right side. The right side of the body 2 is provided with a guide rail groove 21 in the front and rear direction, which forms a sliding fit with the rectangular guide rail protruding strip 12, and is aligned with the guide rail groove 21 up and down and near the front end. There is a first through hole 22 in the left and right direction, a keyway 24 for installing a guide flat key is arranged above the first through hole 22, and a counter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com