Patents

Literature

41results about How to "Easy machining accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

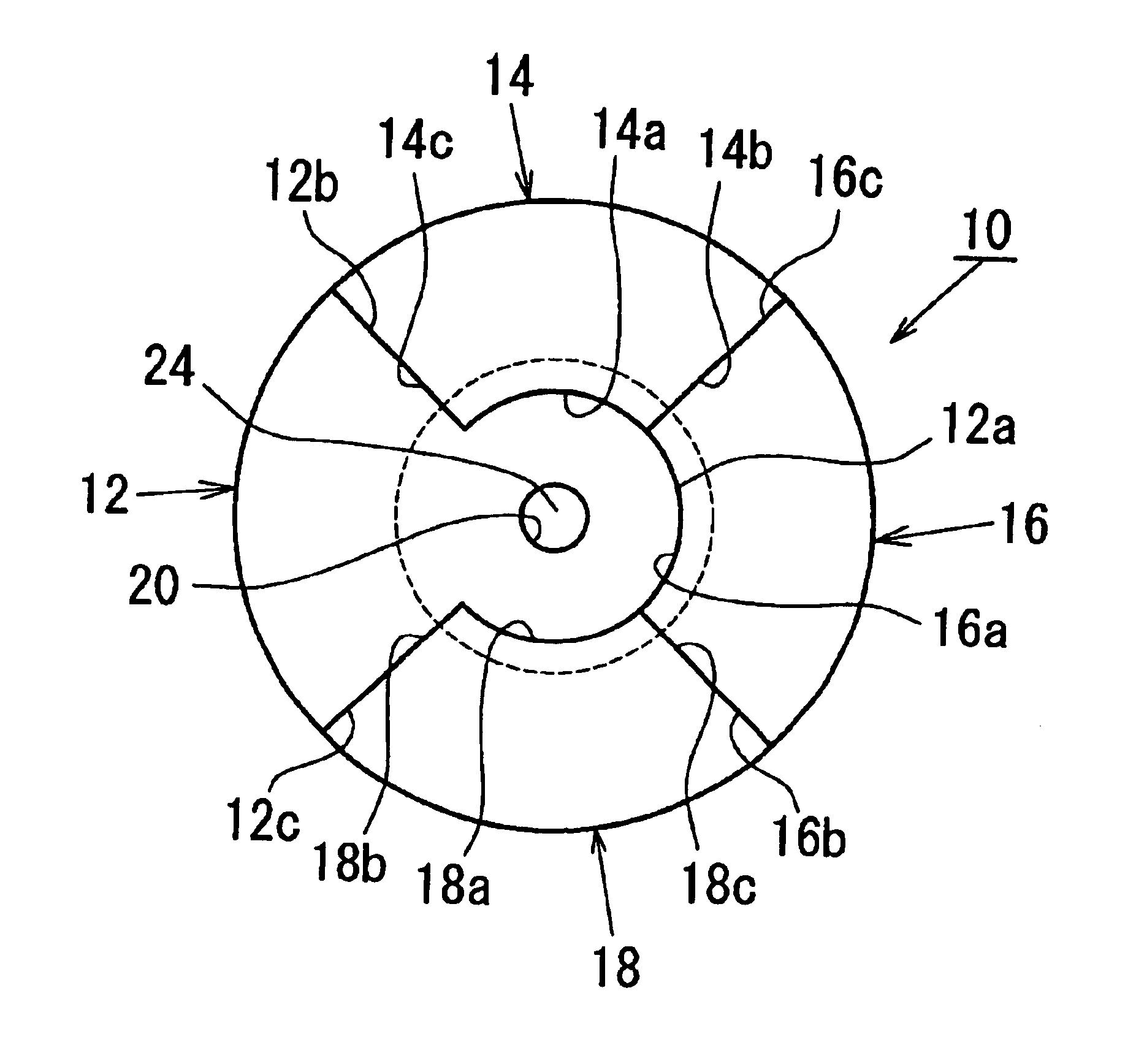

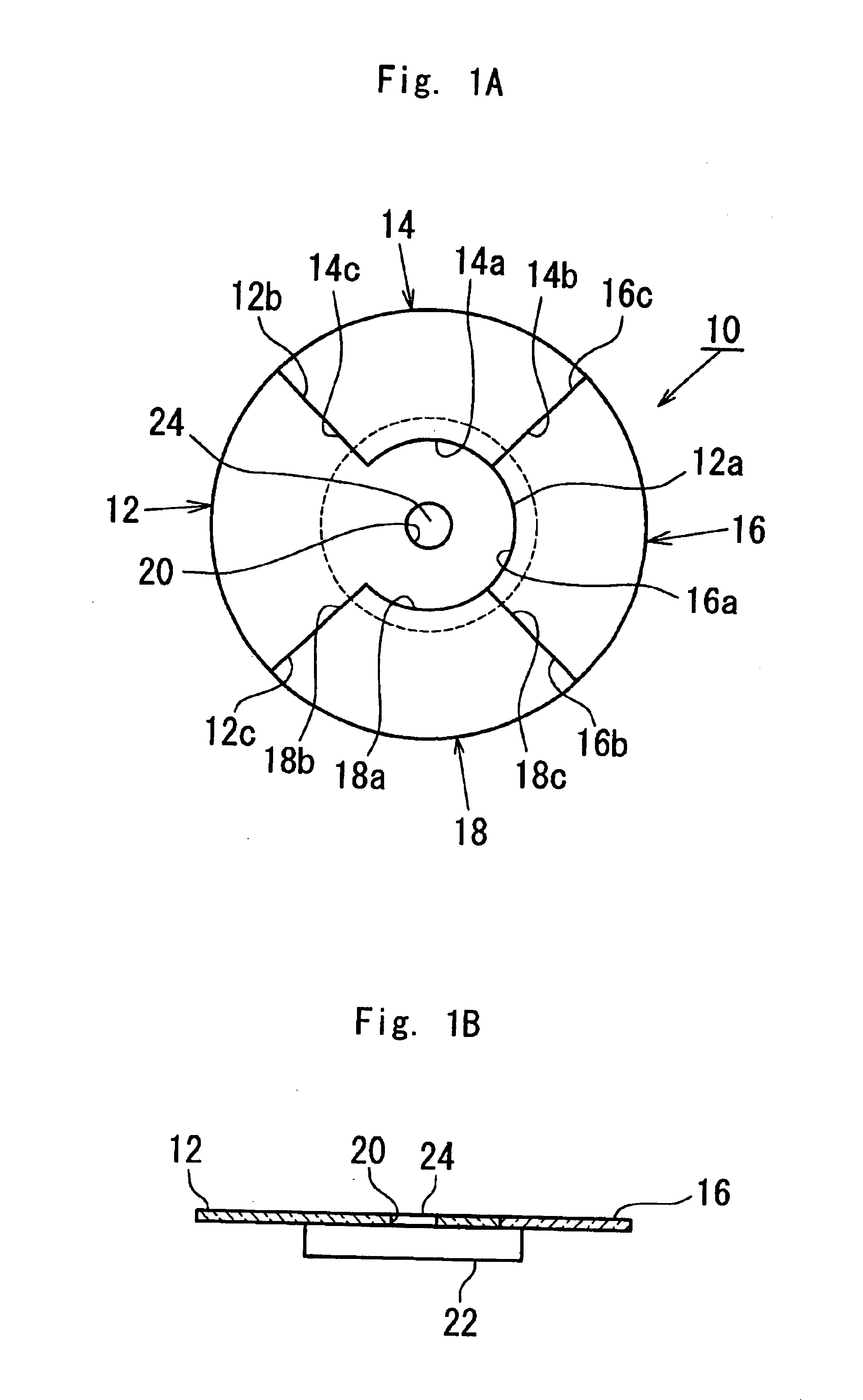

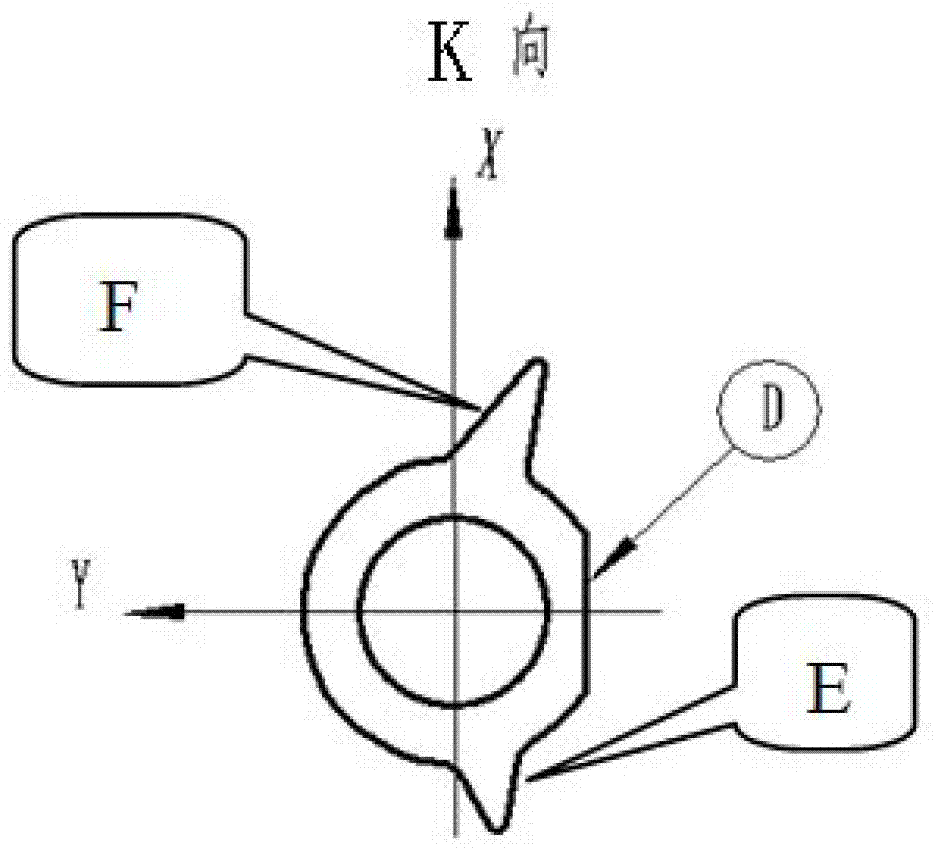

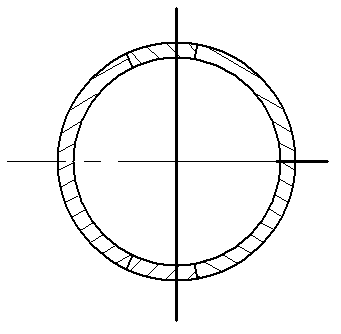

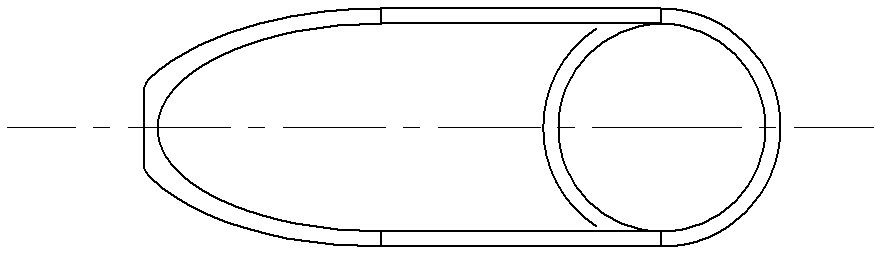

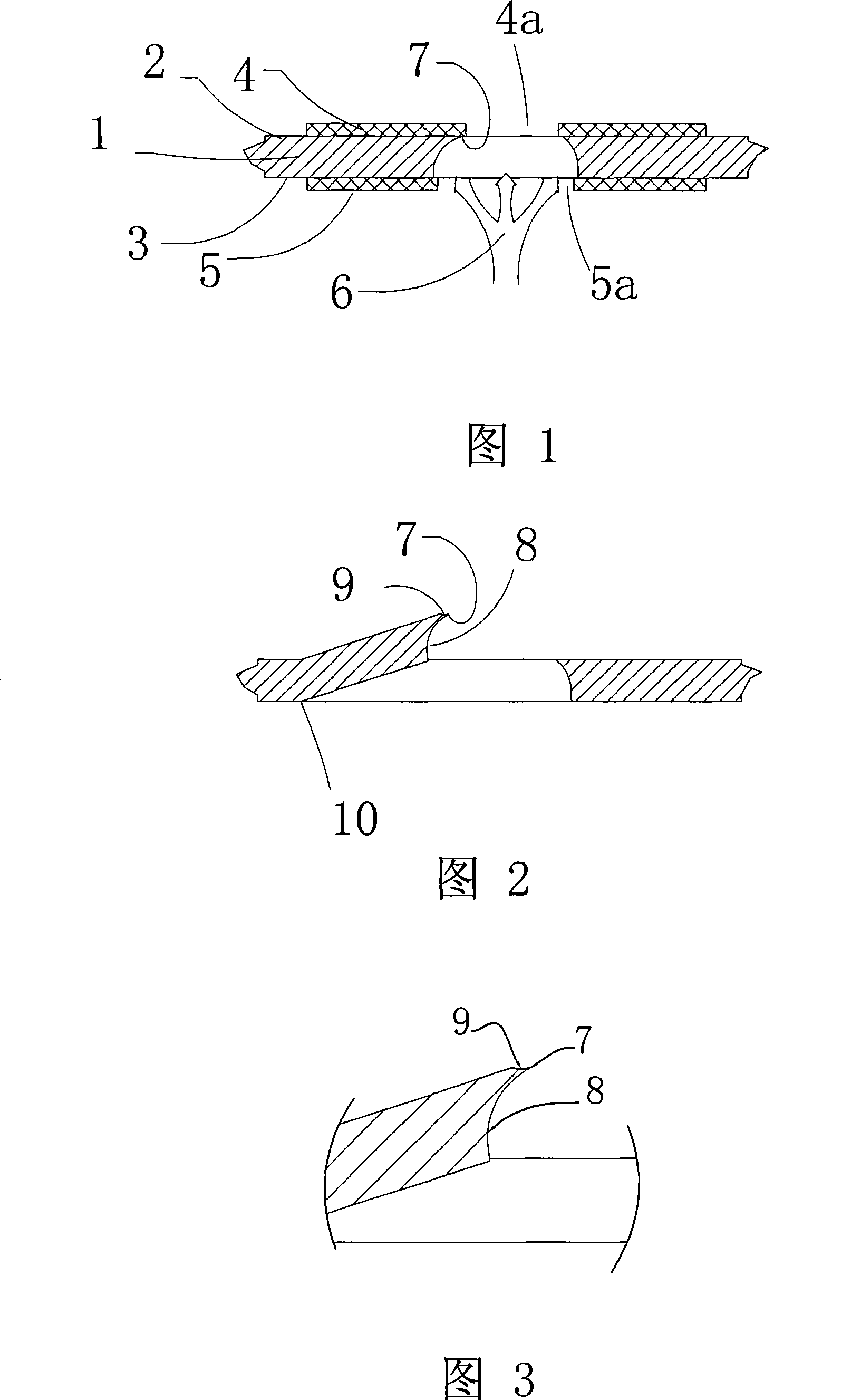

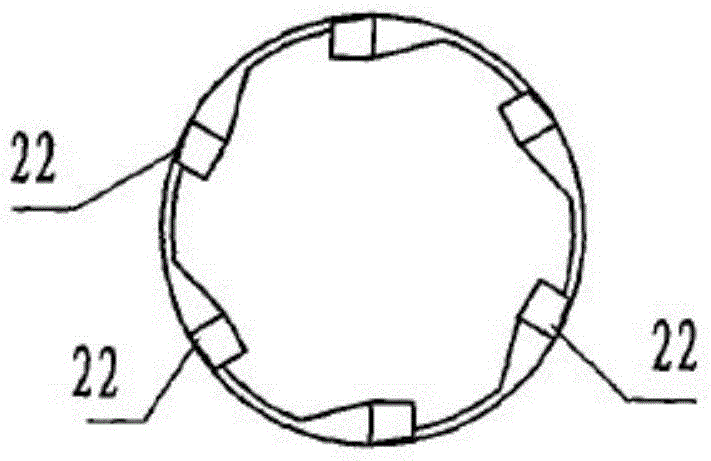

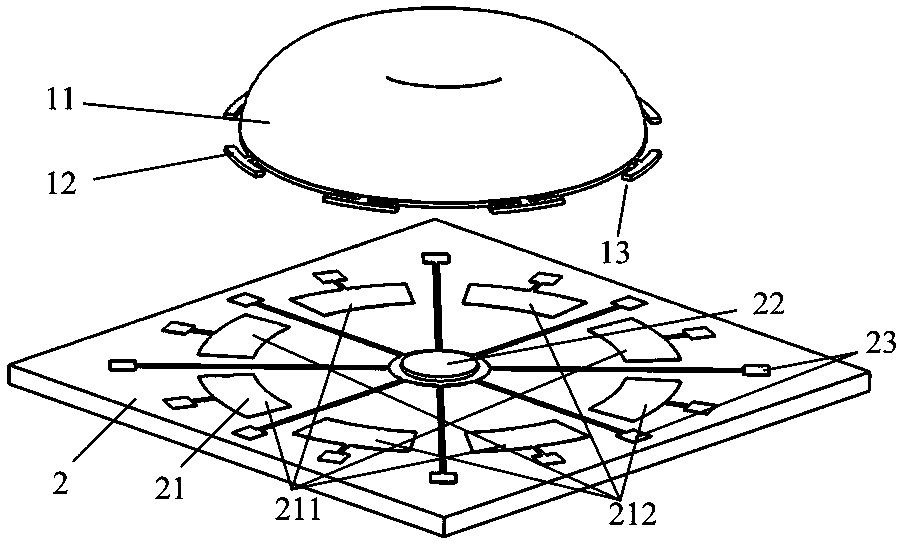

Color wheel of segment type

InactiveUS6963457B1Easy alignmentEasy to fixProjectorsColor/spectral properties measurementsColor gelEngineering

In a color wheel comprising plurality of color filter segments, one of the filter segments consists of a sector portion, and a circular core portion which is formed intergrally at the inner circumferential area of the sector portion, and which is located at the center of the wheel assembled. The inner circumferences of the remaining filter segments are fitted directly to the outer perimeter of the circular core portion of the one segment, whereby the geometric accuracy of the color wheel can be achieved. Also, the alignment process of the filter segments for preventing the color wheel from generating vibrations and noises at the time of spinning at high speed can be simplified or even eliminated thus preventing the number of manufacturing processes from increasing.

Owner:MINEBEA CO LTD

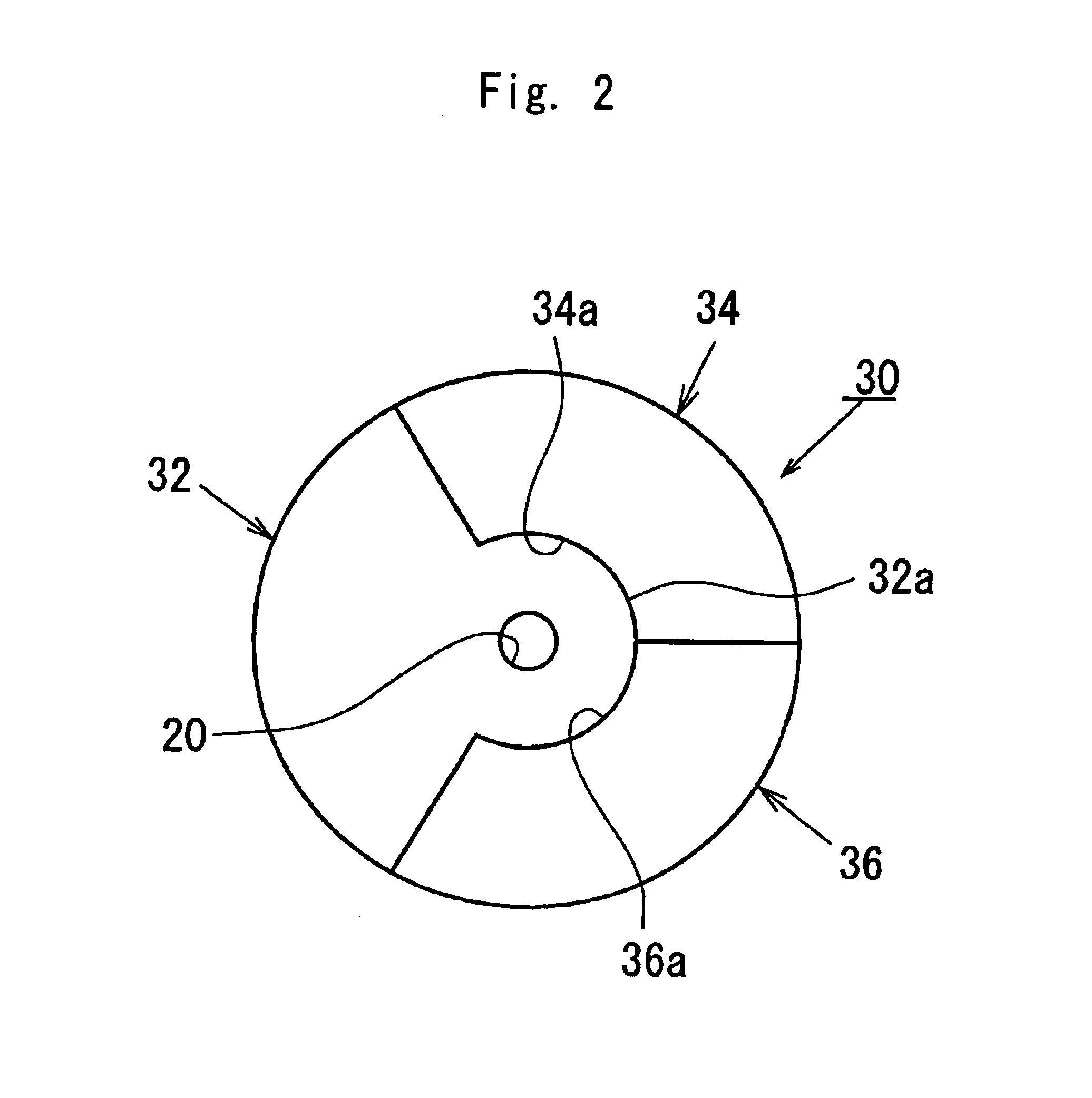

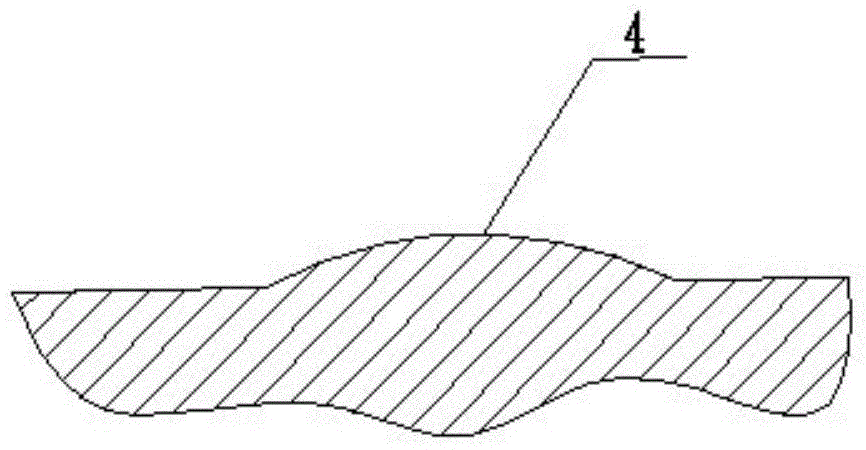

Method for quickly measuring blade surfaces by inductive measuring instrument

InactiveCN102853754AReduce process preparation timeEasy machining accuracyElectric/magnetic contours/curvatures measurementsUsing electrical meansContactorData value

A method for quickly measuring blade surfaces by an inductive measuring instrument particularly includes firstly, adjusting the position of a measurer and the position of a measuring contactor; secondly, measuring combined errors of a standard part, creating references based on the center of a front journal, the center of a rear journal, the front end surface and side planes of a reference frame by a three-coordinate measuring machine, respectively measuring three suction surface or pressure surface sample plates according to specified point positions, and using differences between measured values and data values given by a design drawing as combined error values of suction surface or pressure surface sides; thirdly, adjusting an initial measuring zero position of the inductive measuring instrument, and starting zeroing setting for a suction surface or pressure surface by software functions; fourthly, correcting the zero position to eliminate the combined error values of the combined standard part; and fifthly, measuring a blade. The method has the advantages that the integral standard part of the traditional complex three-dimensional curve blade surface is simplified into a split structure beneficial to machining and manufacturing, manufacturing difficulty for the standard part is greatly reduced, manufacturing cycle is shortened, cost is low, precision is high, and measurement efficiency is greatly improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Multichip typesetting substrate and manufacturing method thereof

ActiveCN103025056AImprove connection strengthLimit thicknessPrinted circuit assemblingPrinted circuits structural associationsEngineeringUltimate tensile strength

Owner:IBIDEN ELECTRONICS BEIJING

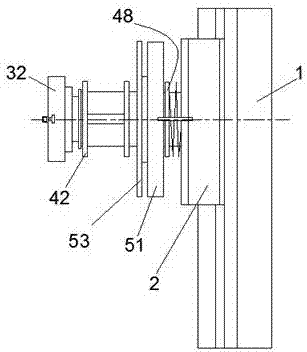

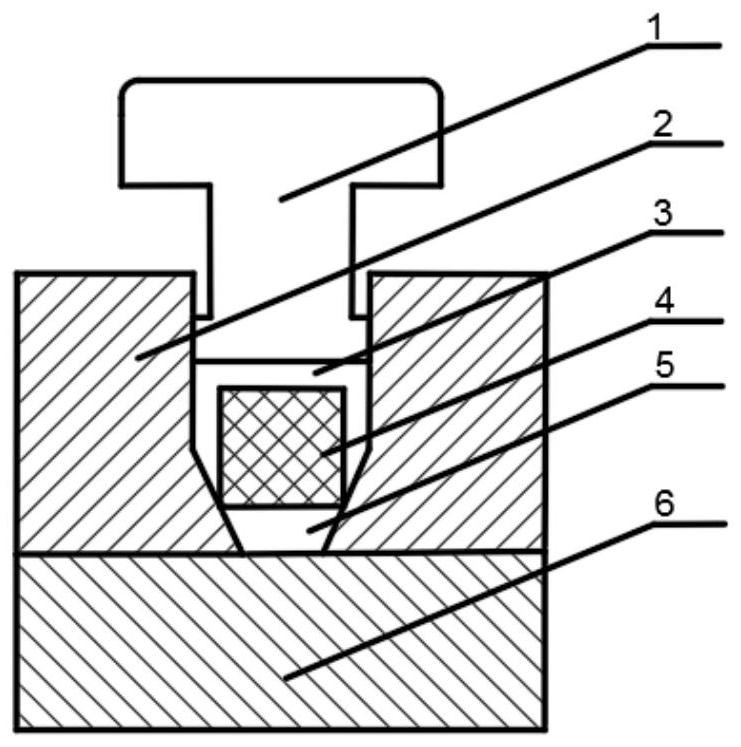

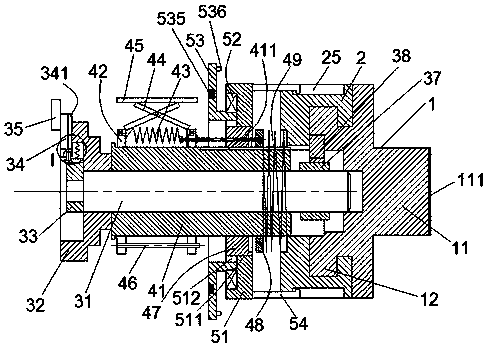

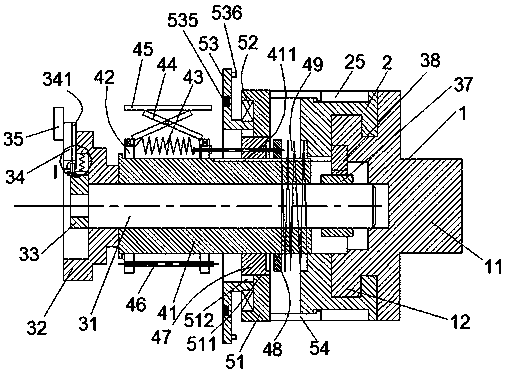

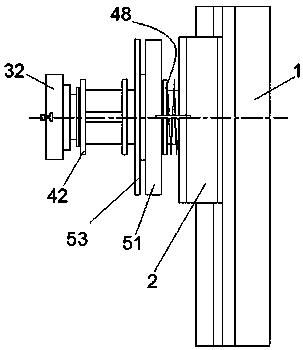

Inner groove machining device for lathe

ActiveCN107470652ARealize processingControl Radial DimensionsTool holdersTurning machinesForward backwardEngineering

The invention discloses an inner groove machining device for a lathe. The inner groove machining device comprises a clamping piece, a body, a groove depth control device, an axial positioning dimension control device and a clamping device. A long rectangular raised strip is arranged on the left side of the clamping piece, and rectangular guide rail raised strips in the forward-backward direction are arranged on the upper surface and the lower surface of the right side of the clamping piece correspondingly; a guide rail groove slidably matched with the rectangular guide rail raised strips is formed in the right side of the body in the forward-backward direction; the groove depth control device is mounted on the left side of the body and rightwards penetrates through a first through hole to finally stretch into a combined groove in the middle of the right side face of the clamping piece; the clamping device is mounted in the position, located on the left side of the body, of the groove depth control device; and the axial positioning dimension control device is mounted on the clamping device. The dimension is controlled conveniently, operation is convenient and rapid, the machining precision can be guaranteed, and additionally, the machining efficiency can be improved.

Owner:广州市新帅机械制造有限公司

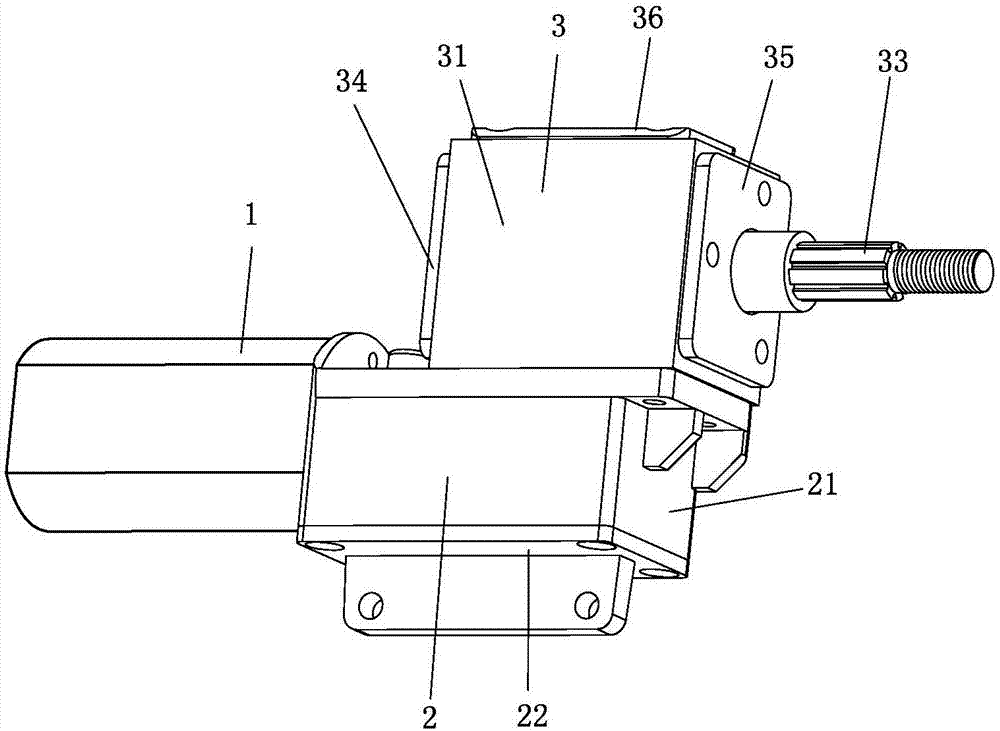

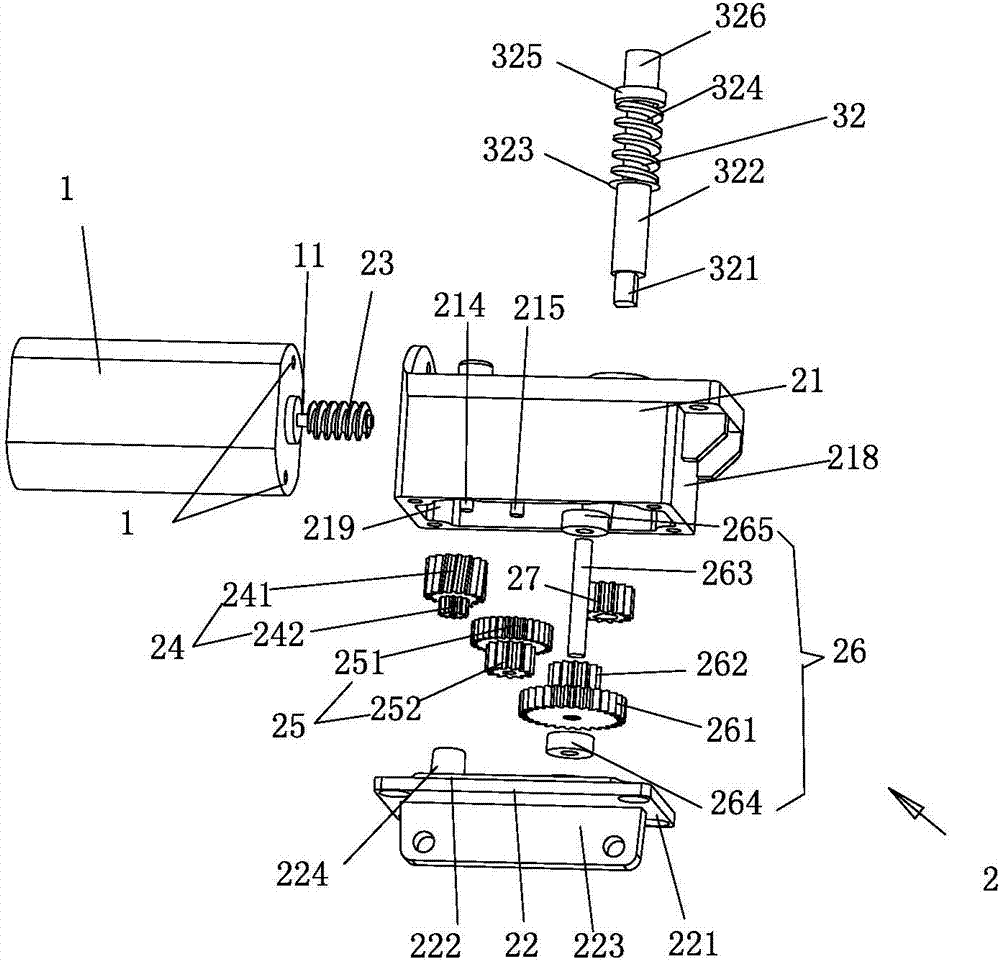

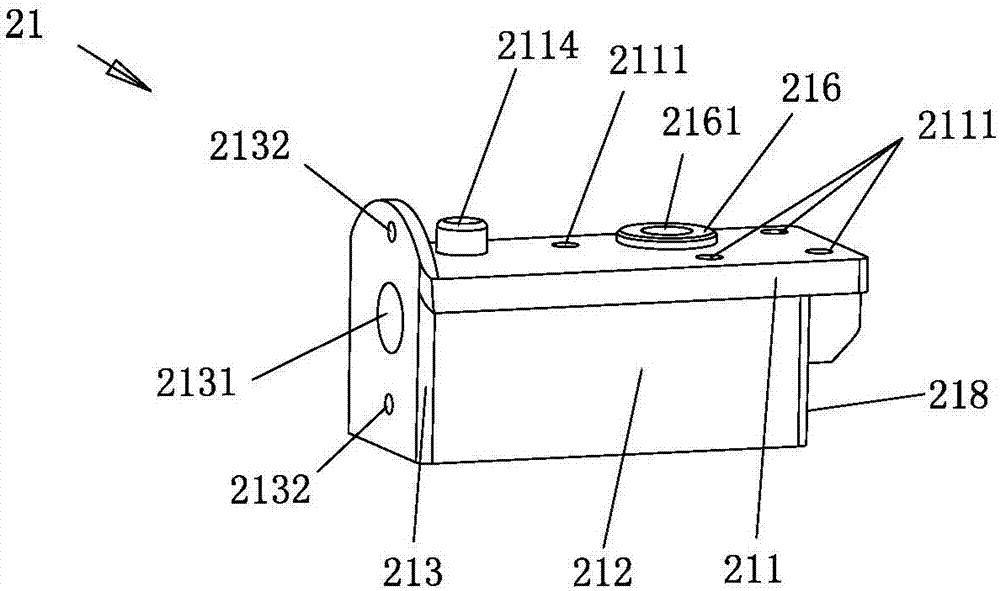

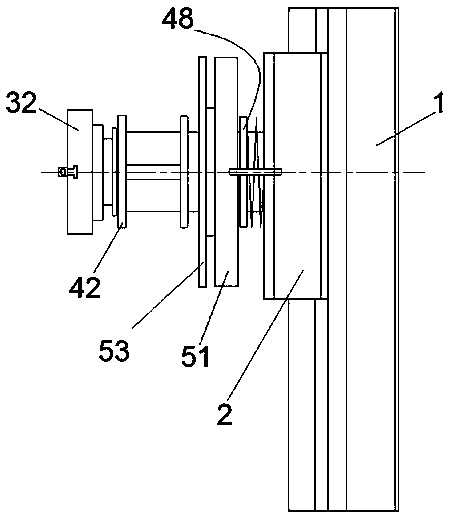

Turn-over driving device of vehicle-mounted flat-panel display

PendingCN107542860AReduce processing difficultyEasy to processToothed gearingsVehicle componentsIn vehicleDisplay device

The invention discloses a turn-over driving device of a vehicle-mounted flat-panel display and relates to an electric driving device for changing the supporting state of a display. The turn-over driving device of the vehicle-mounted flat-panel display is provided with a motor and a deceleration mechanism which comprises two rectangular box bodies and two worm gears and two worms. A rotating shaftof the first worm in the deceleration mechanism is a transverse input shaft, a rotating shaft of the second worm gear in the deceleration mechanism is a transverse output shaft, and the two shafts areparallel to each other. Longitudinal bearings are mounted on a lower straight rod part and an upper straight rod part of the two sides of an arc surface thread part of the second worm correspondingly, transverse bearings are mounted on a left circular rod part and a right circular rod part of the two sides of a working part on the second worm gear correspondingly, wherein the working part is provided with a plurality of arc surface tooth grooves along the circumference surface, and the arc surface thread part of the second worm is engaged with the arc surface tooth grooves of the second wormgear. The deceleration mechanism is provided with the two rectangular box bodies, the first worm and the first worm gear are mounted in the first box body, the second worm, the two longitudinal bearings of the second worm, the second worm gear and the two transverse bearings of the second worm gear are mounted in the second box body, and thus machining and production are facilitated.

Owner:XIAMEN XINSHENYUE ELECTROMECHANICAL

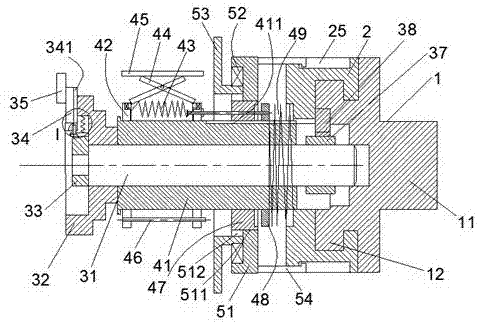

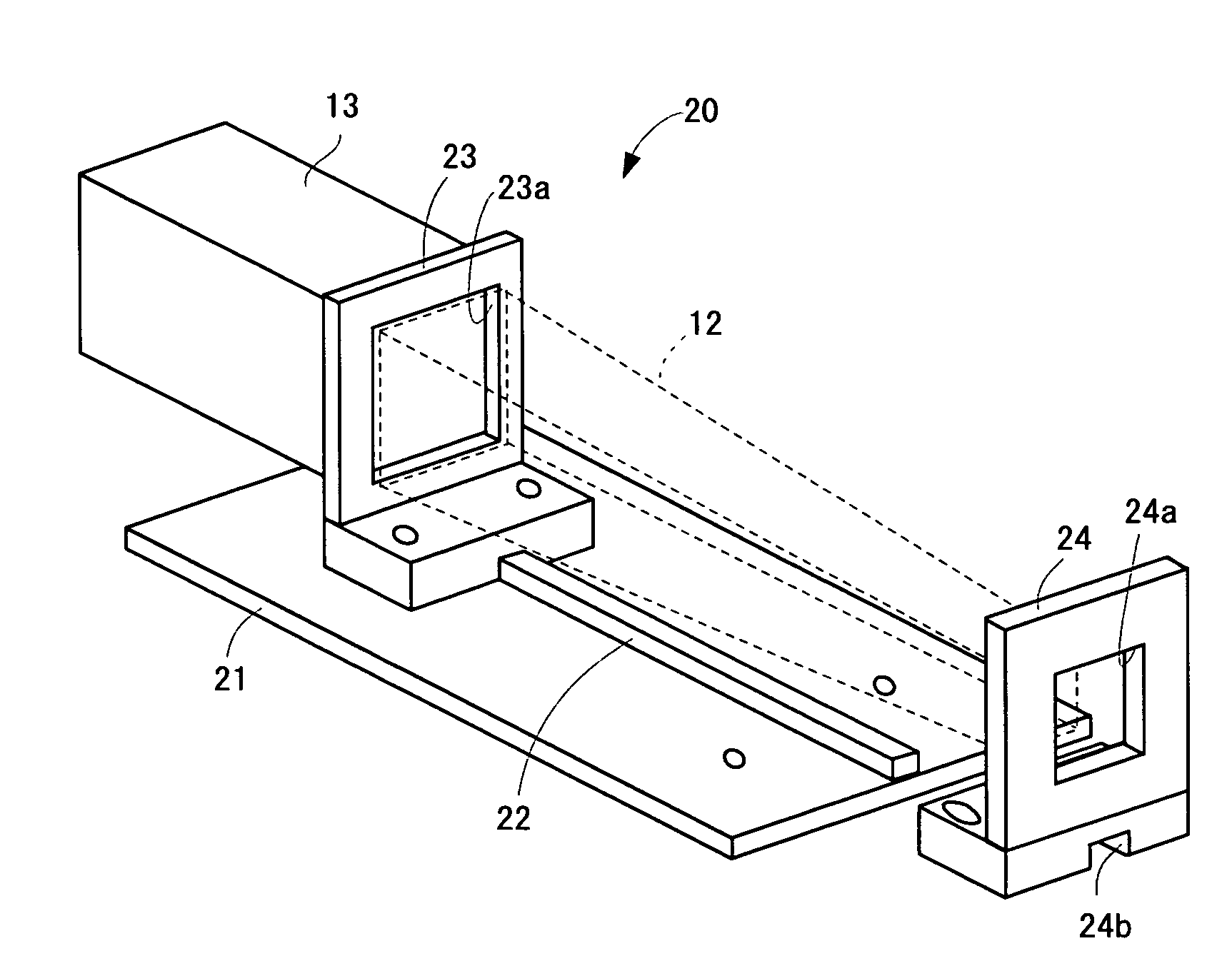

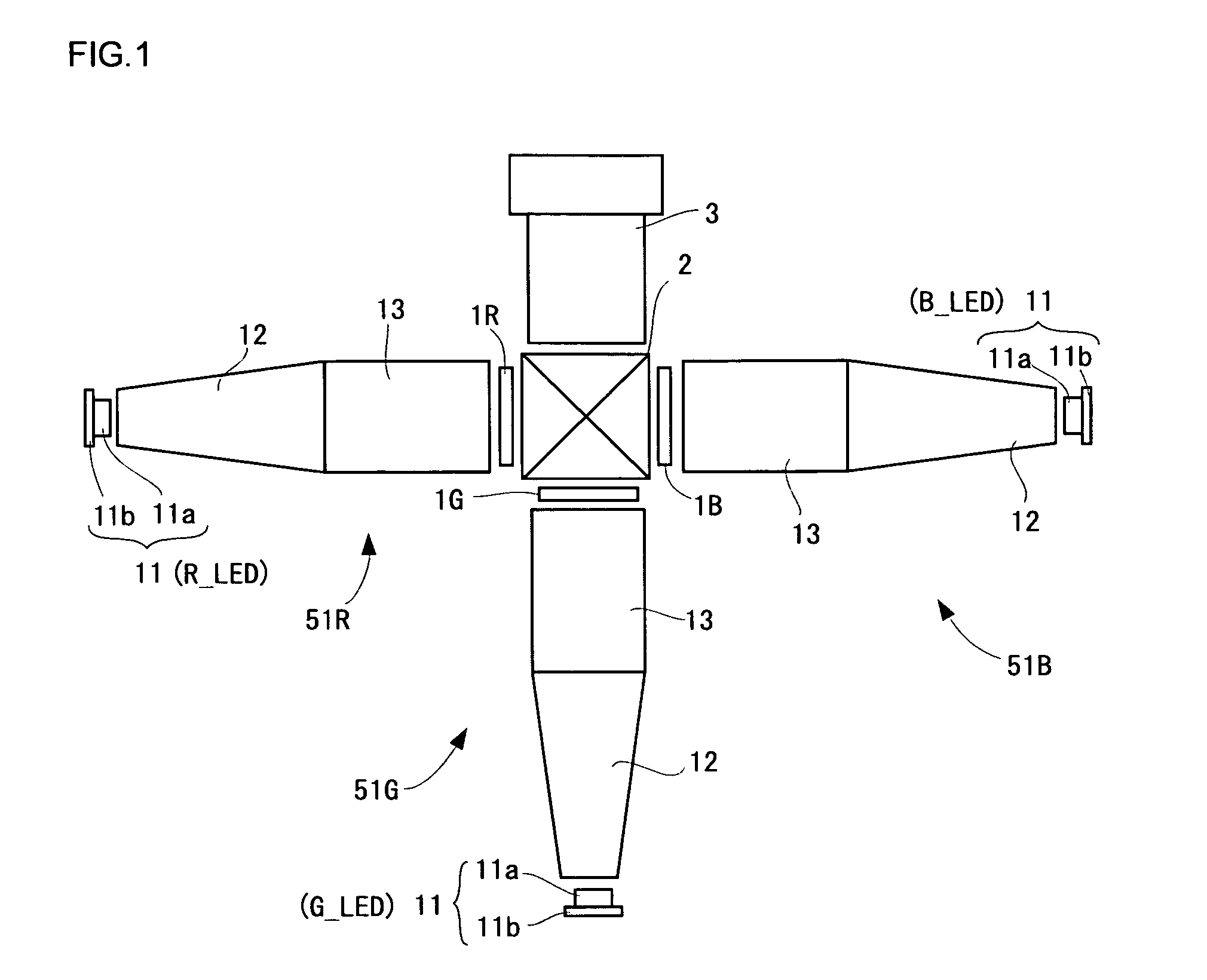

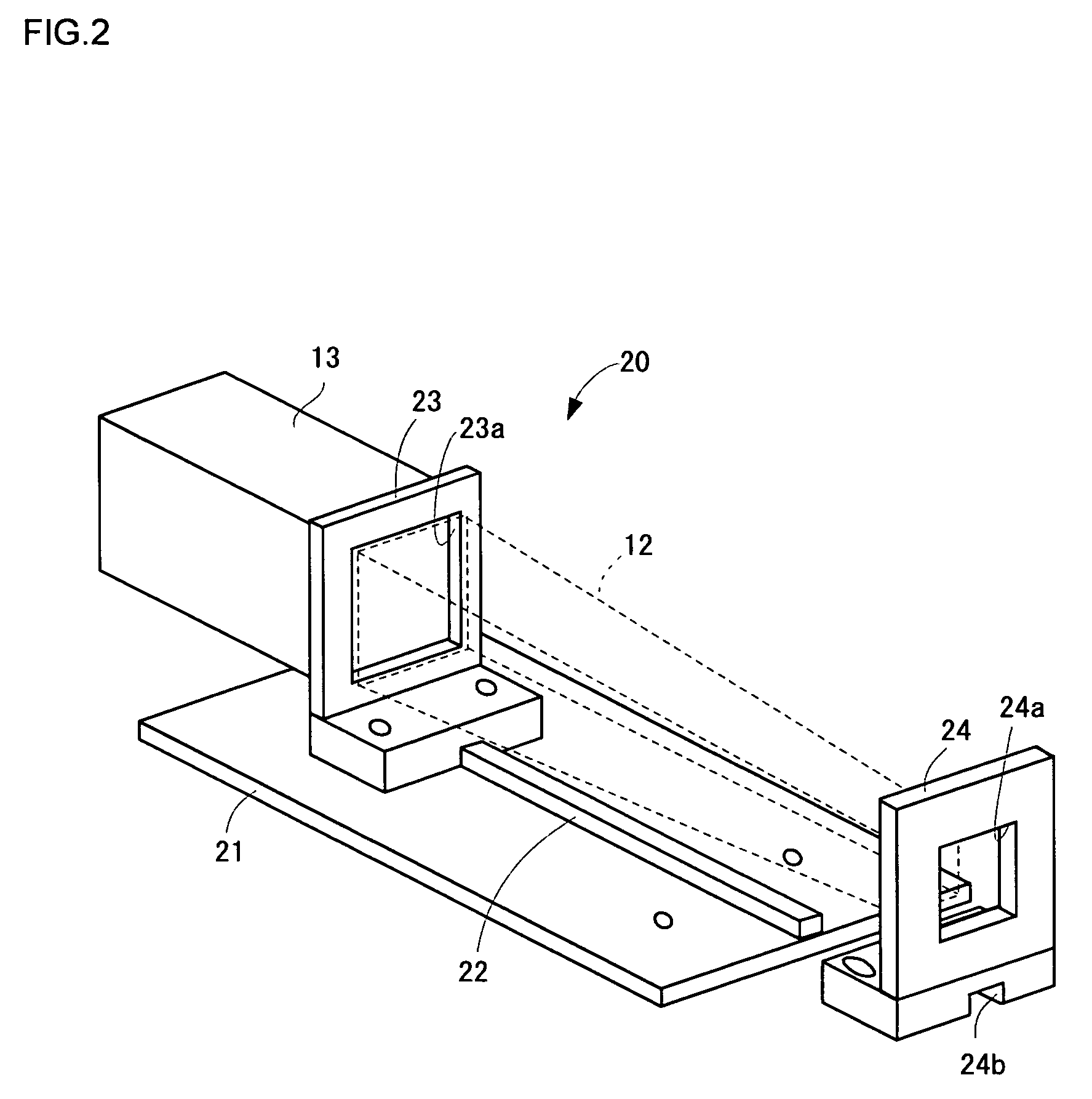

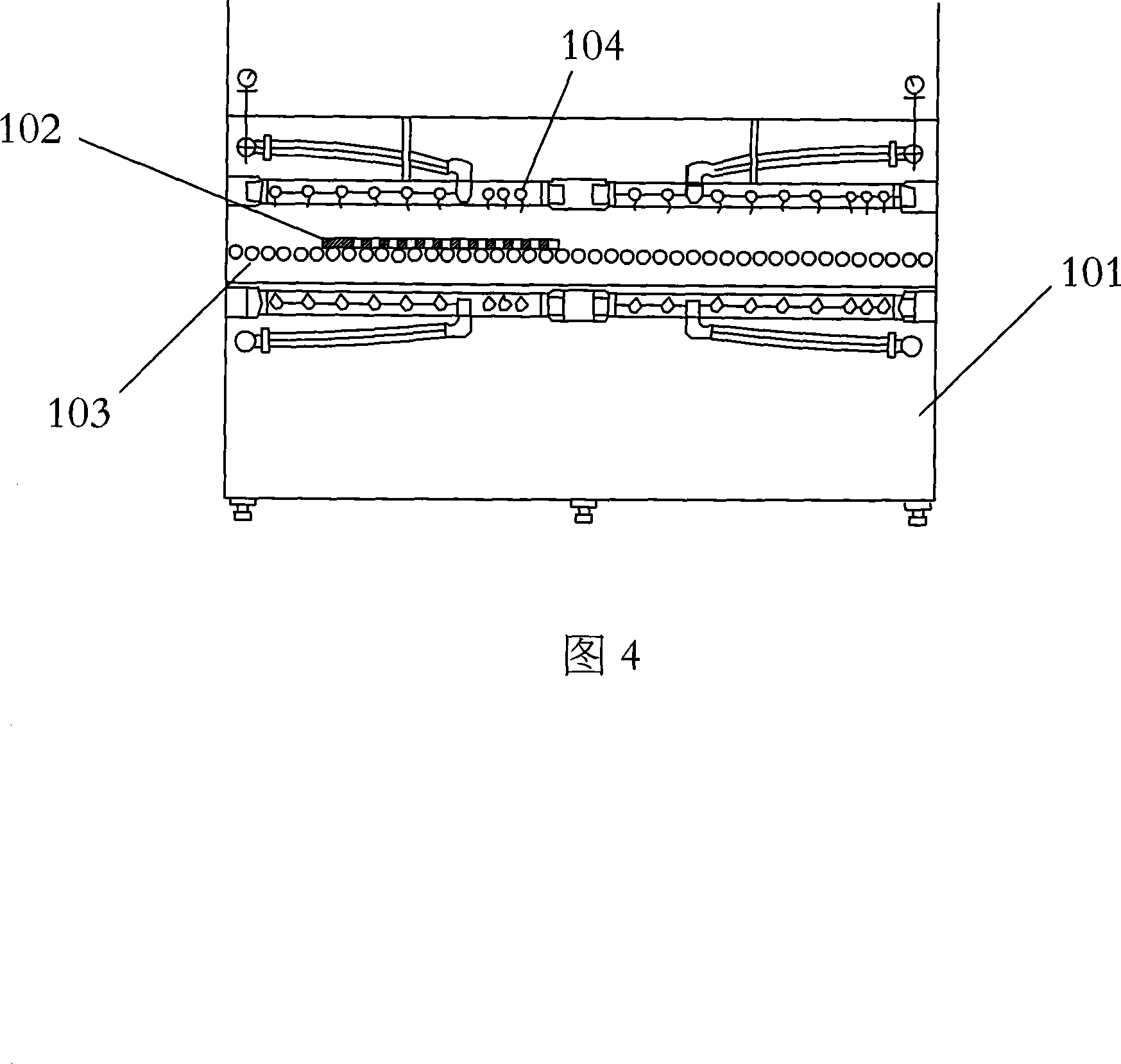

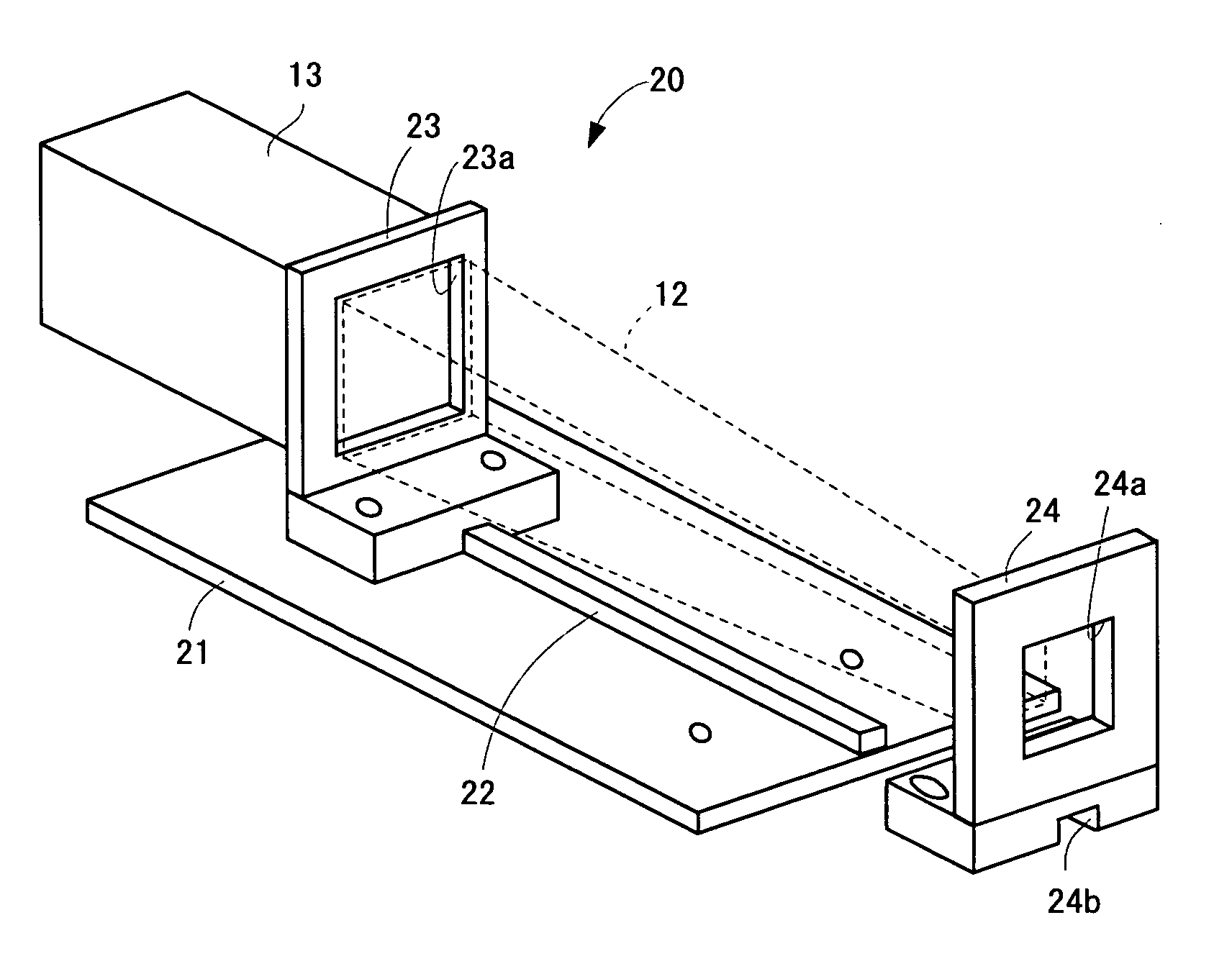

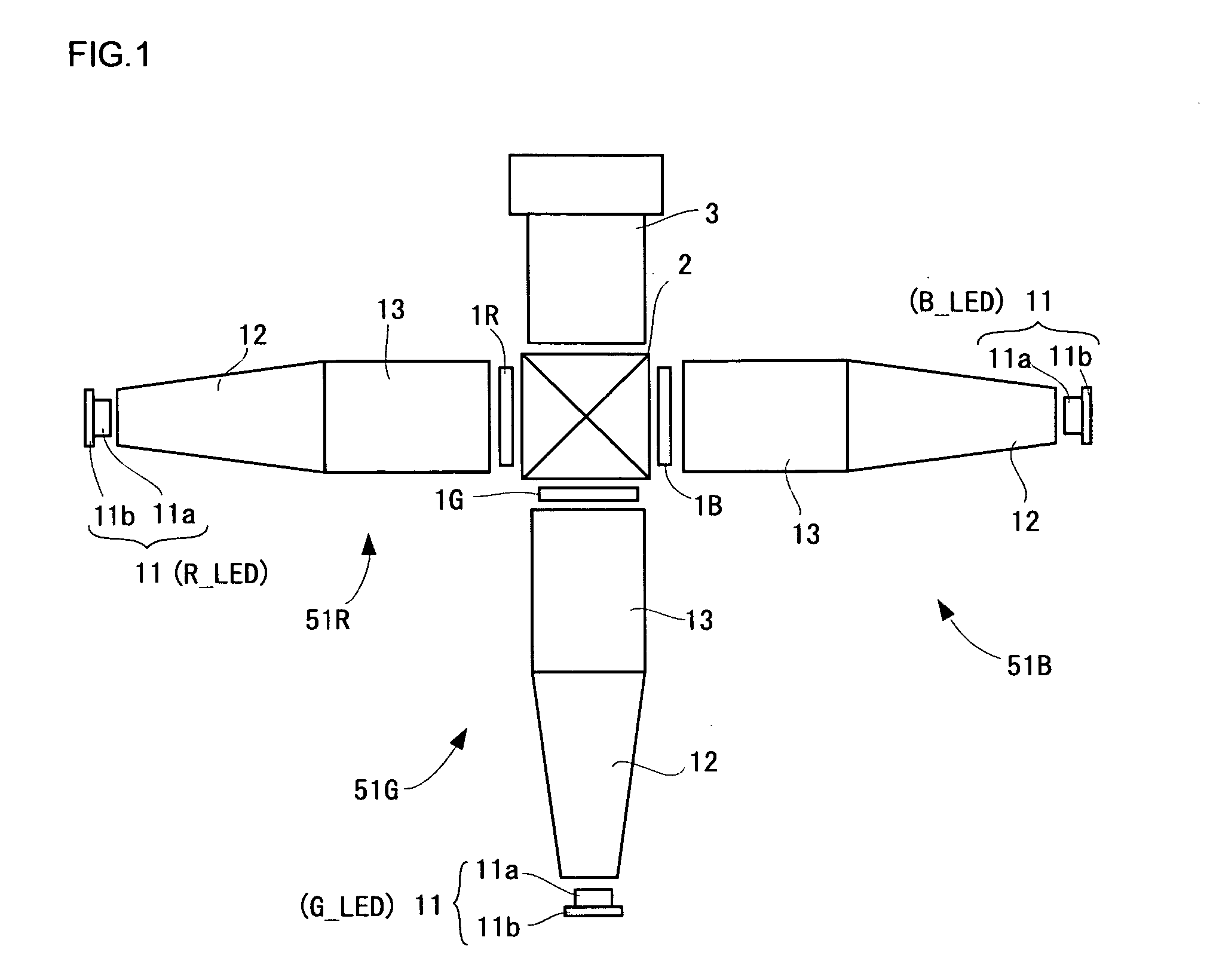

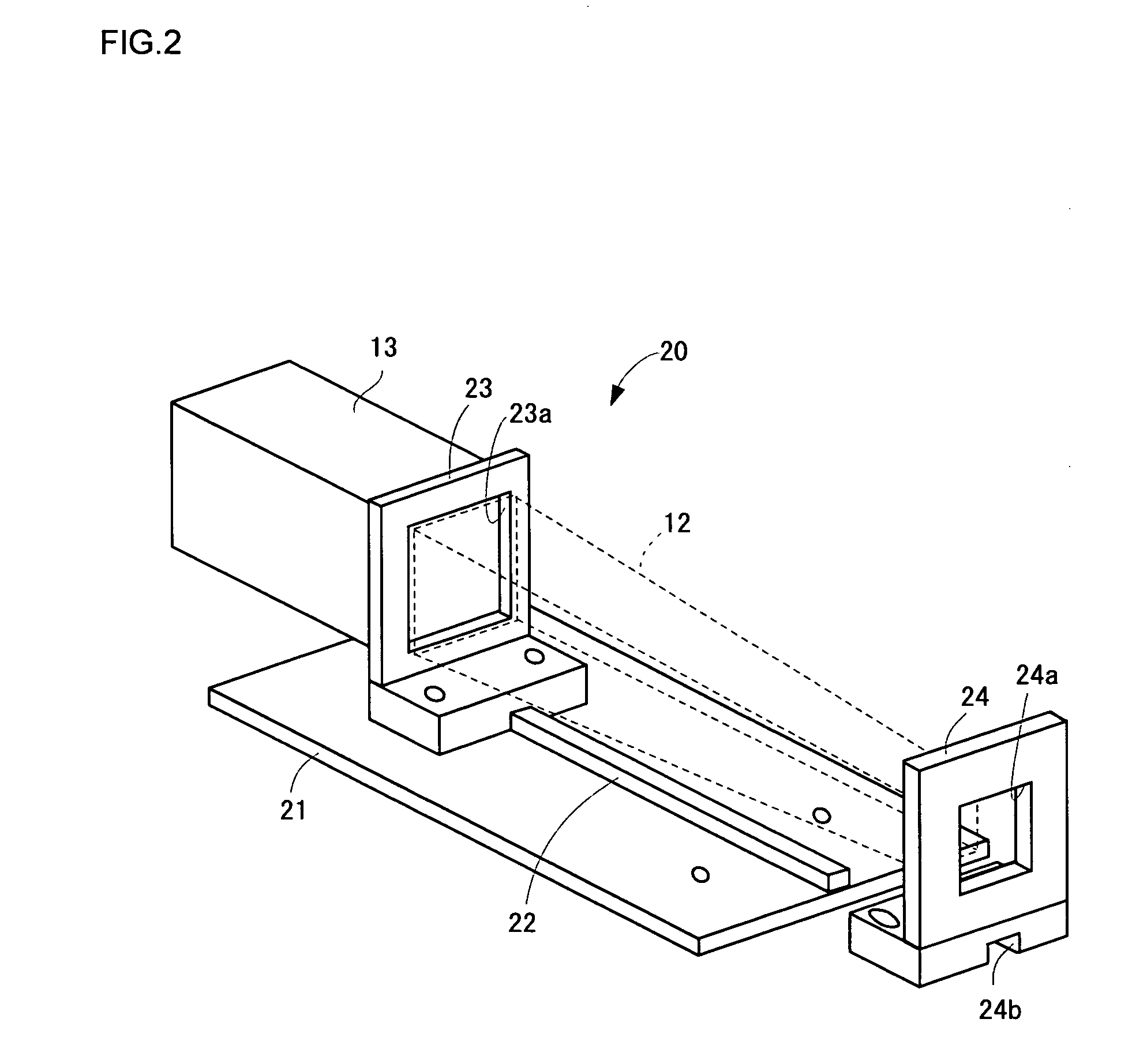

Rod integrator holder and projection type video display

InactiveUS7658497B2Easy machining accuracyEasy to guaranteeProjectorsColor television detailsIntegratorOptical axis

A guide convex portion is formed on a base plate in parallel to an illumination optical axis. Further, a fixed-side supporting member is provided in the base plate. A first opening is formed in an upright portion of the fixed-side supporting member. A slide supporting member can be provided on the base plate. A second opening is formed in the upright portion of the slide supporting member. By inserting a tapered rod into the second opening at its light incidence side and by moving the slide supporting member along the aforementioned guide convex portion, the slide supporting member is stopped at a predetermined position and, at this position, the slide supporting member is fixed.

Owner:SANYO ELECTRIC CO LTD

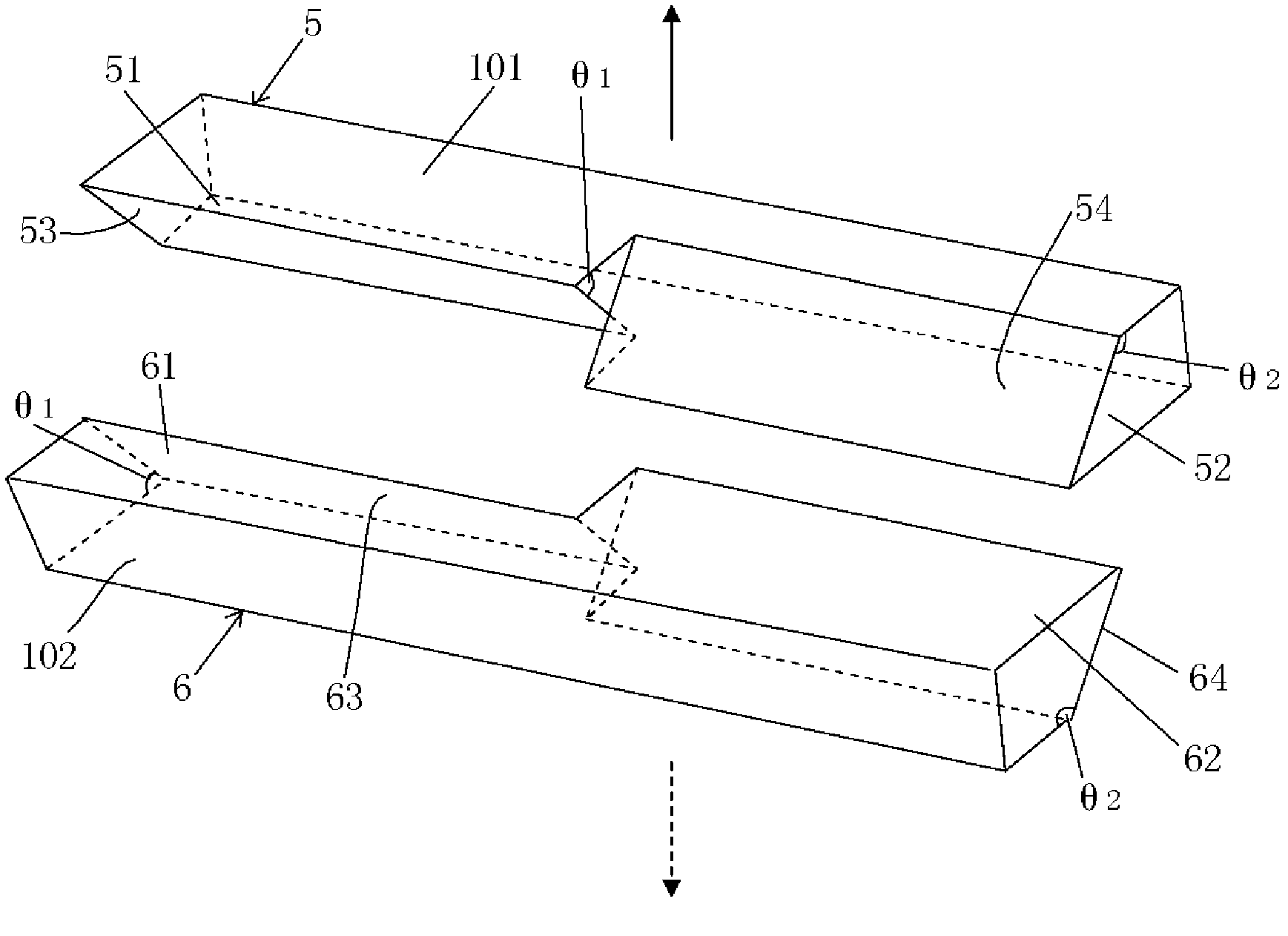

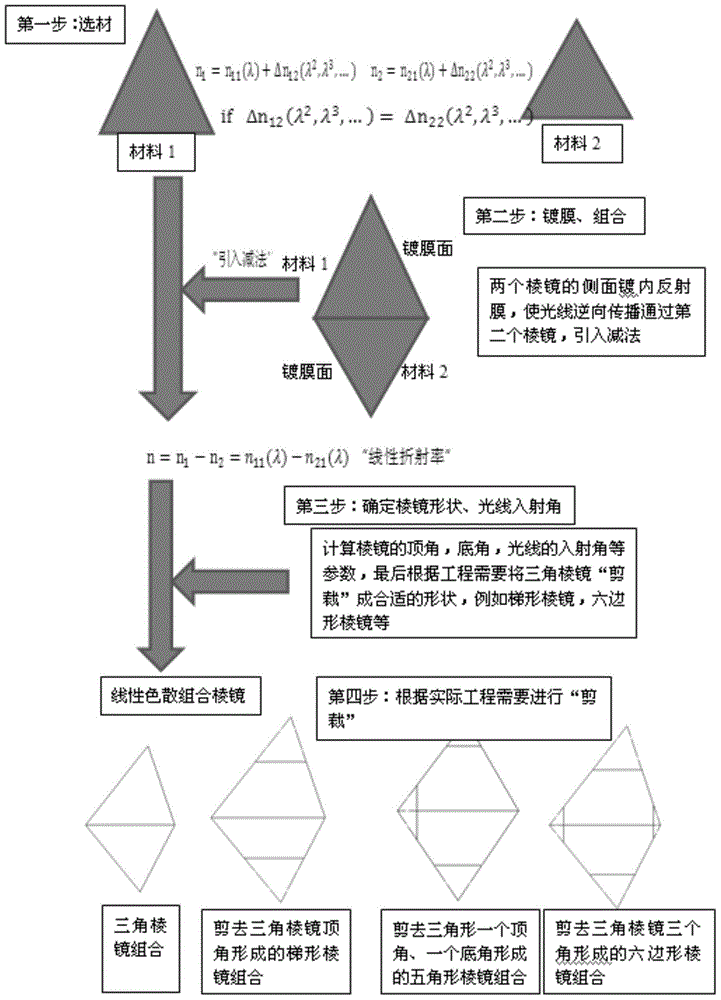

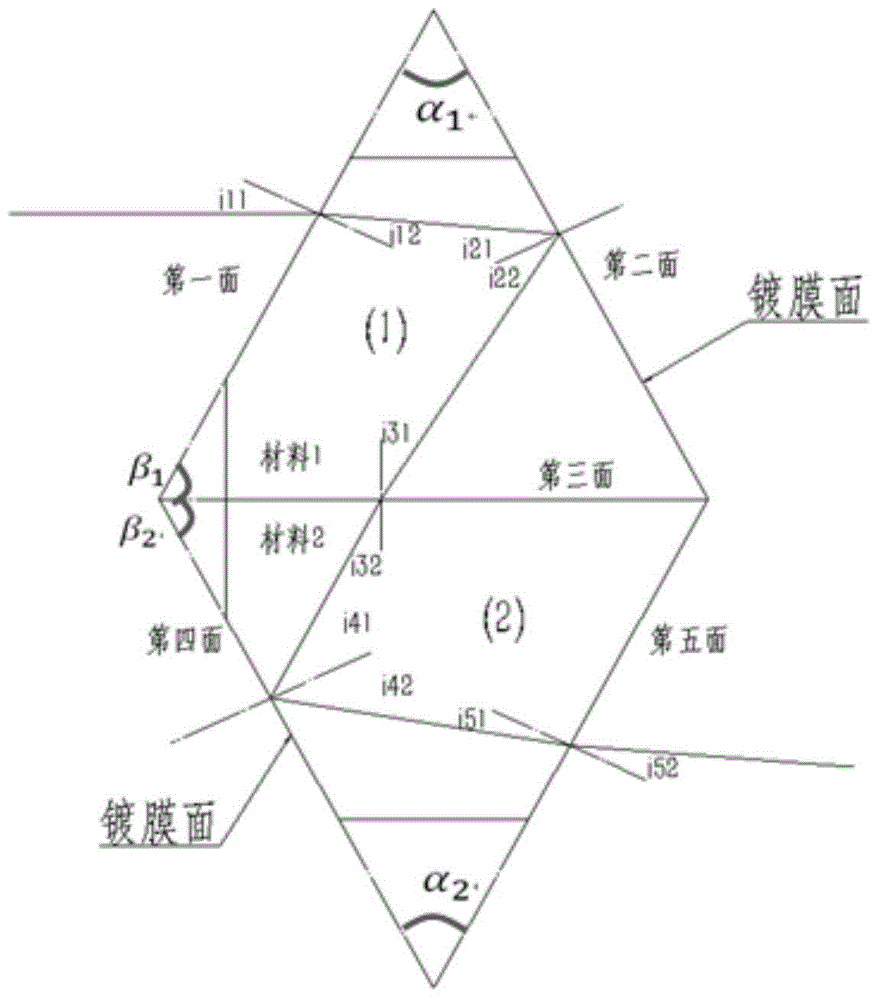

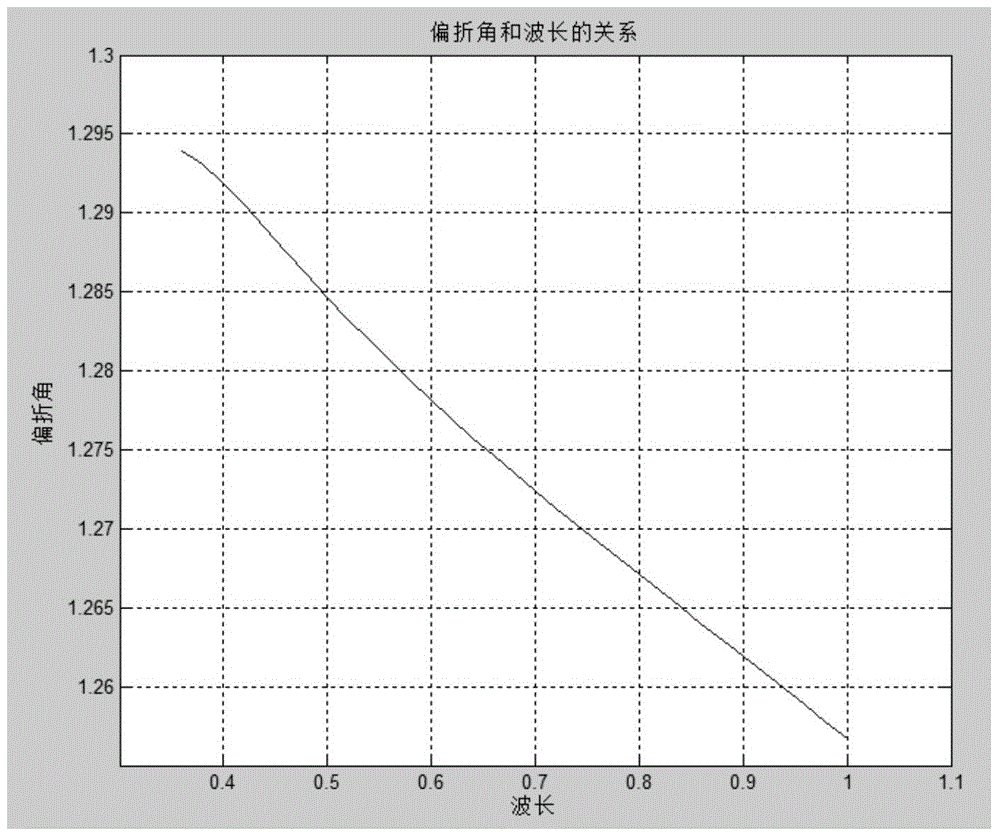

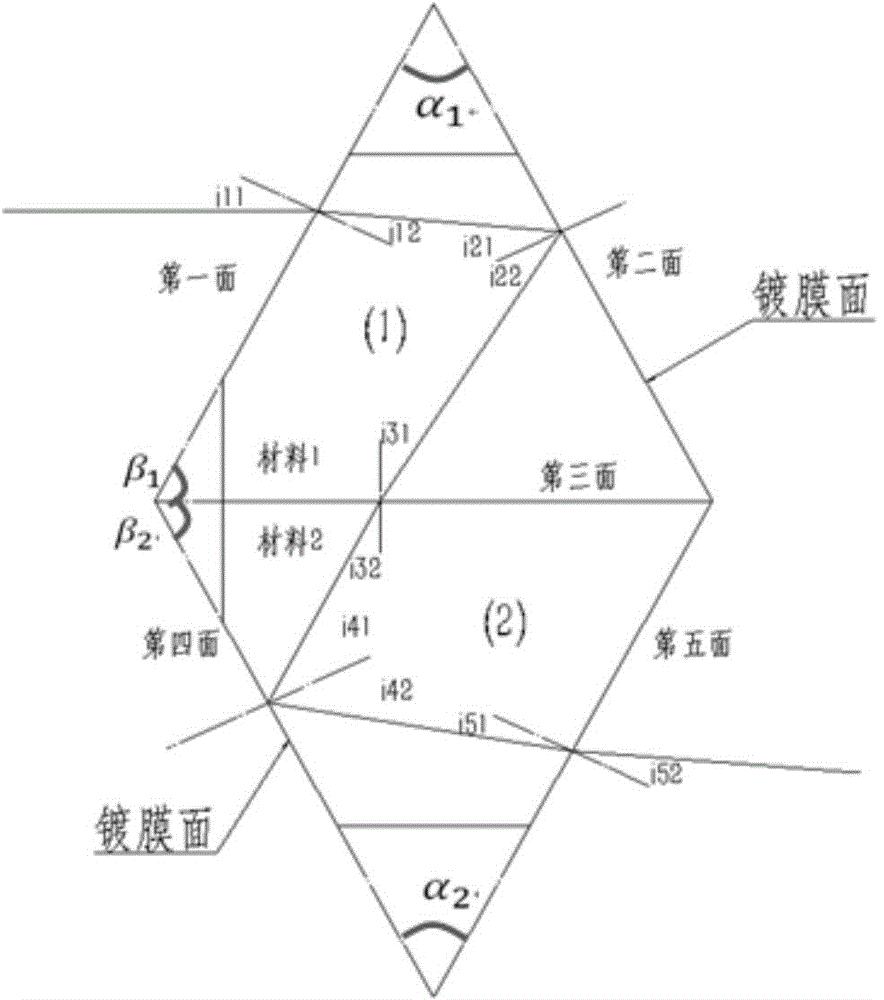

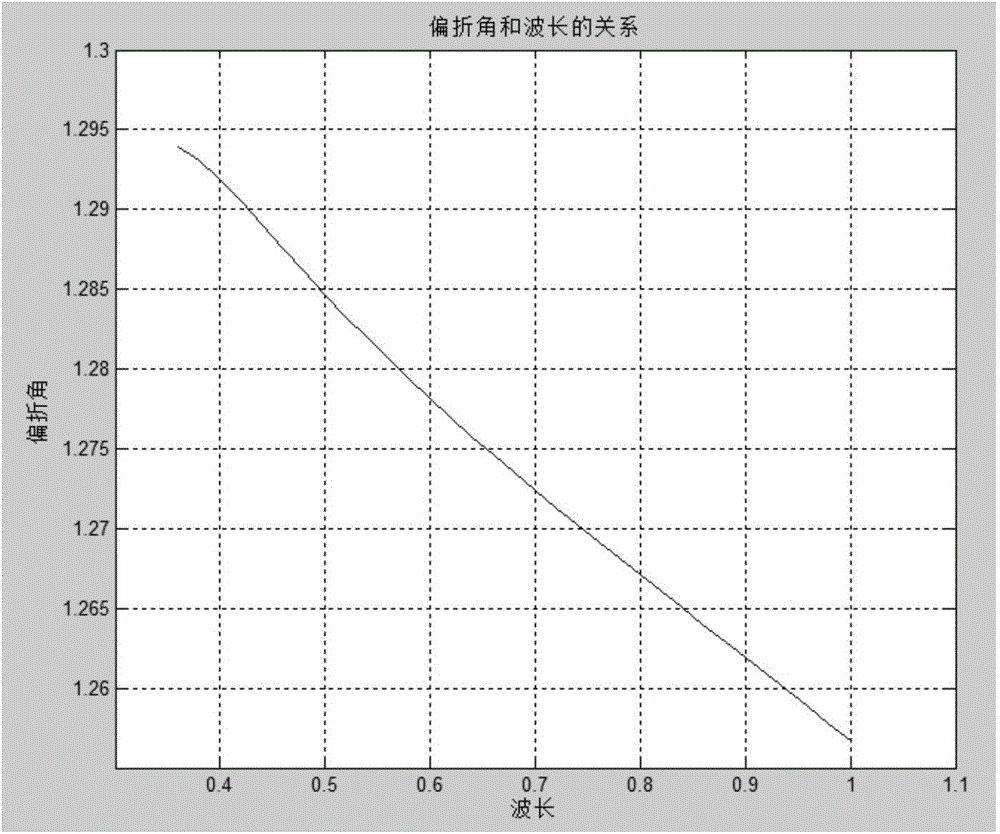

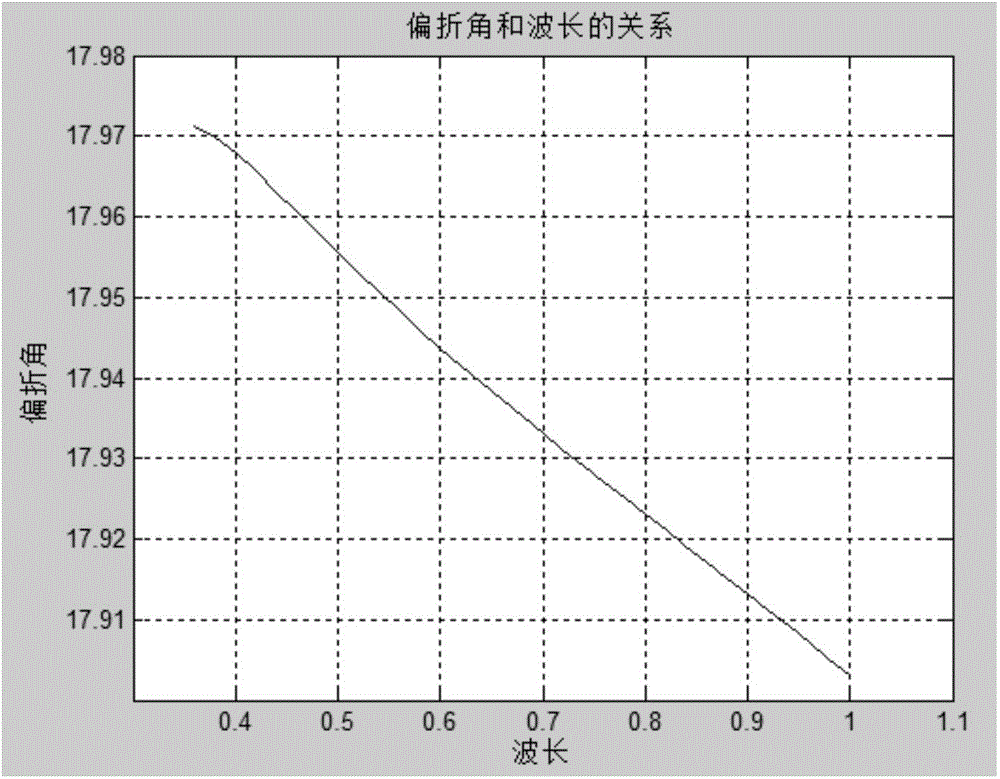

Linear chromatic dispersion combined prism beam splitting device

The invention discloses a linear chromatic dispersion combined prism beam splitting device which is formed by combining two prisms made of a special selected material and provided with coating films on the side faces in the mode of 'bottom surface adhesion and opposite coating film faces'. The linear chromatic dispersion combined prism beam splitting device is especially suitable for spectral analysis, spectrum detection and other relevant fields. Based on a control variable method and a differential equation thought, the non-linear chromatic dispersion of the second prism is utilized to compensate non-linear chromatic dispersion of the first prism so as to obtain the linear chromatic dispersion combined prism beam splitting device by controlling light propagation direction and the shapes of the prisms according to the chromatic dispersion characteristic of a first prism material. The linear chromatic dispersion combined prism beam splitting device overcomes the defect of chromatic dispersion non-linearity of the single prism and has the advantages of being wide in free spectral range, high in light energy utilization rate, good in universality, simple in structure, low in price and the like.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

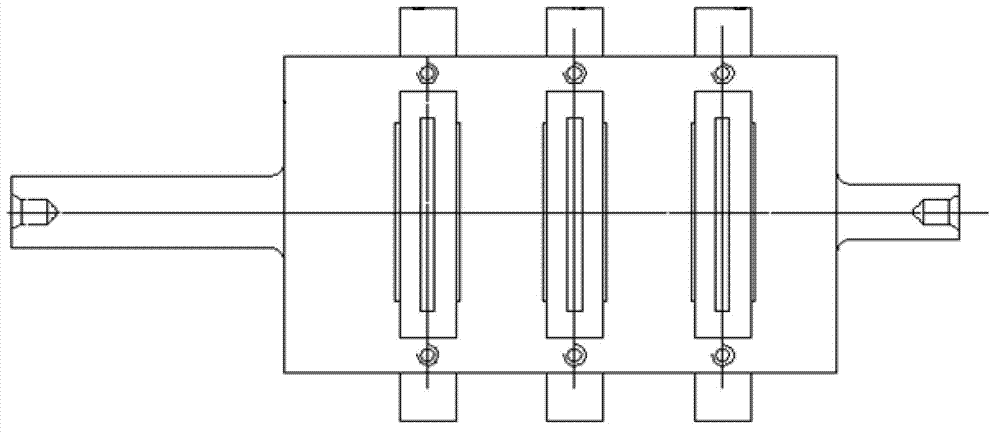

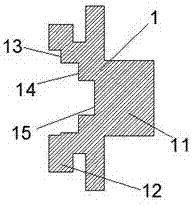

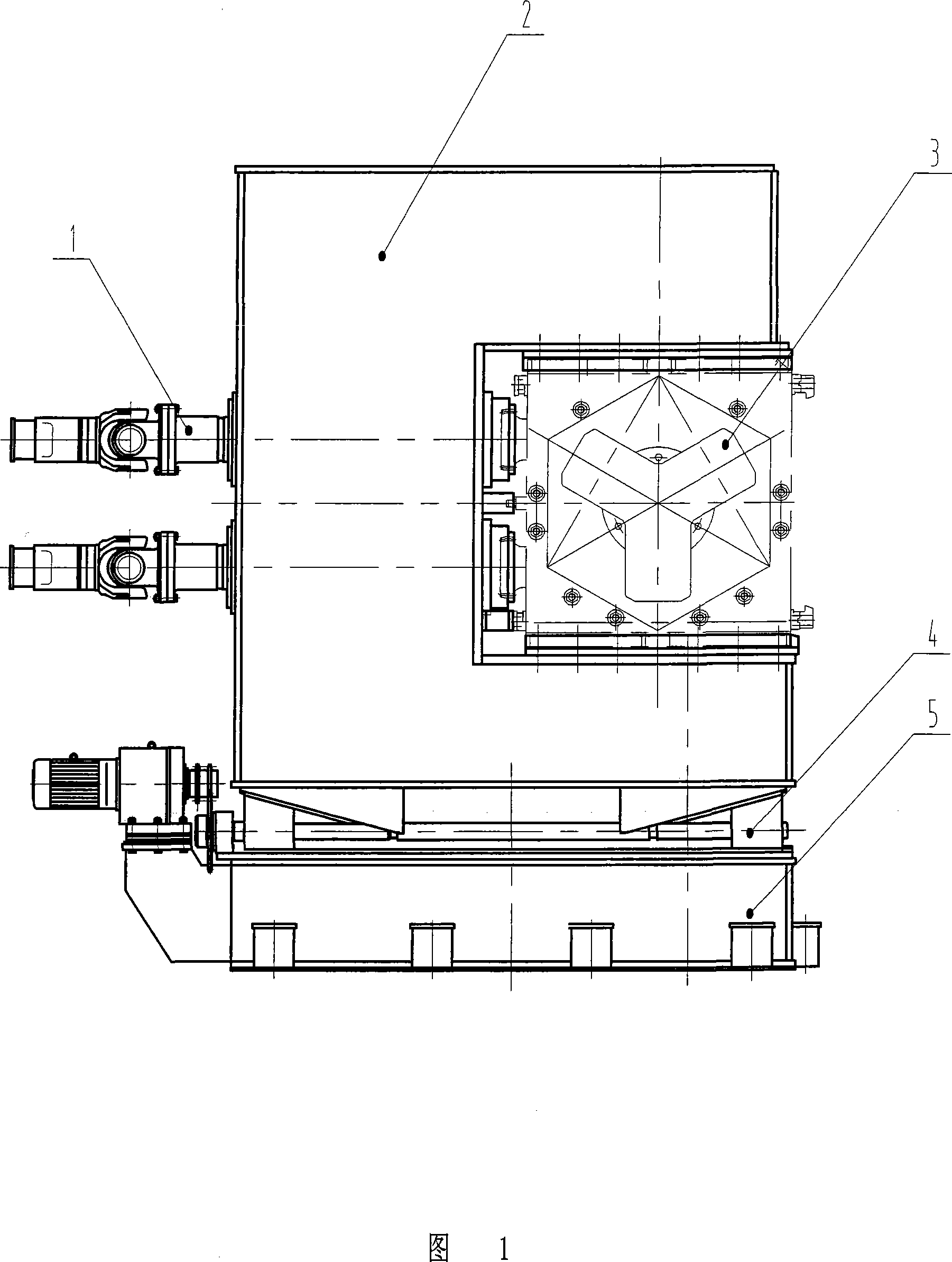

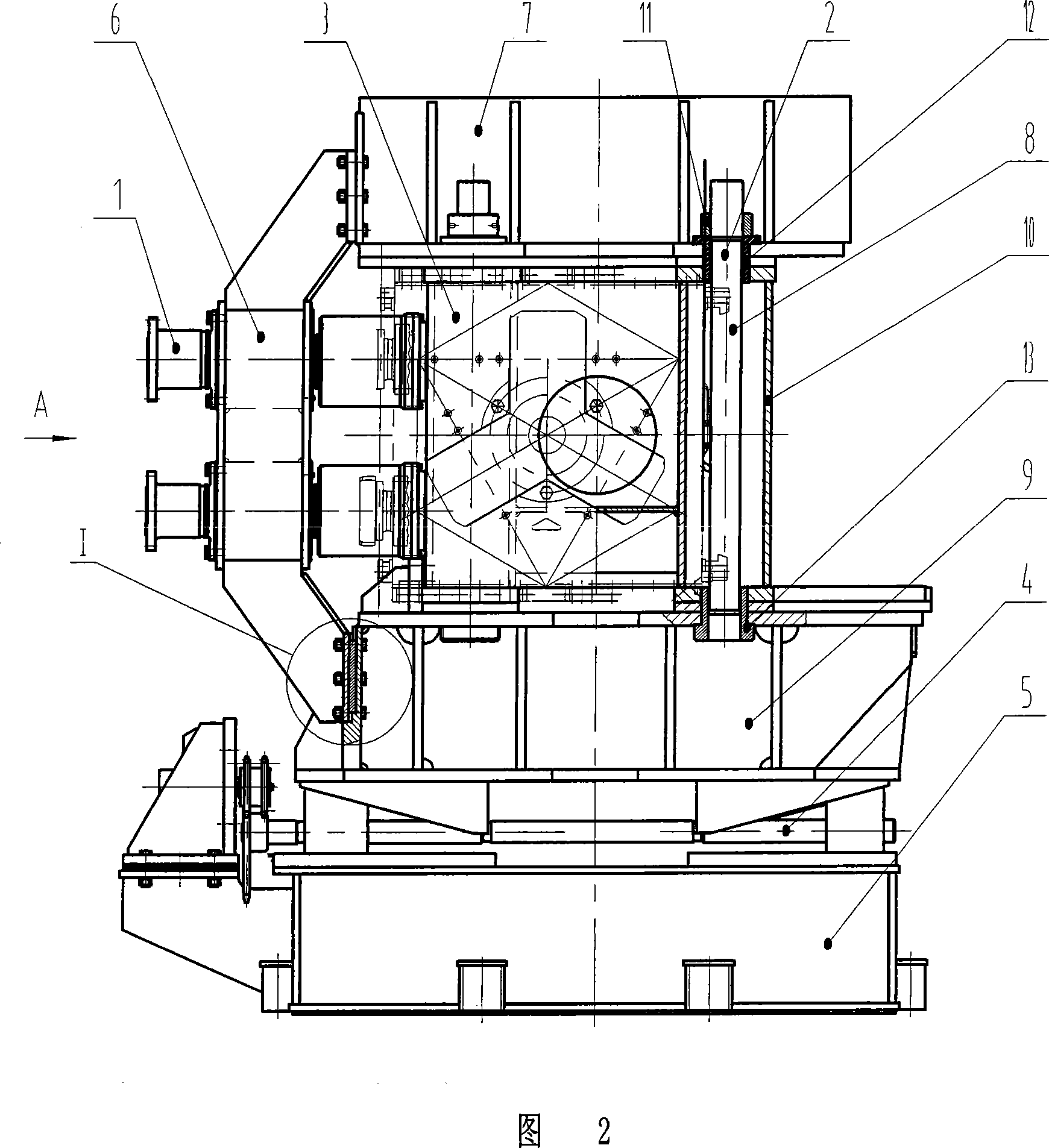

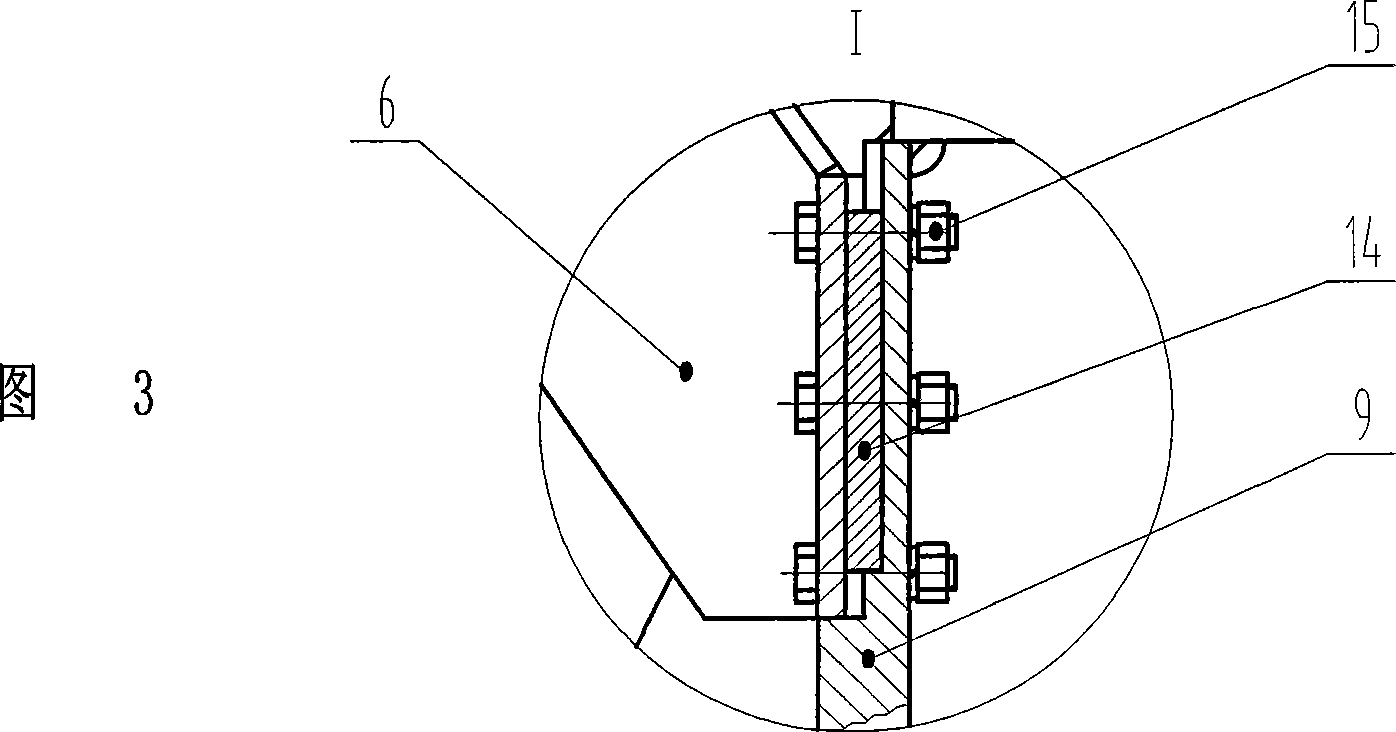

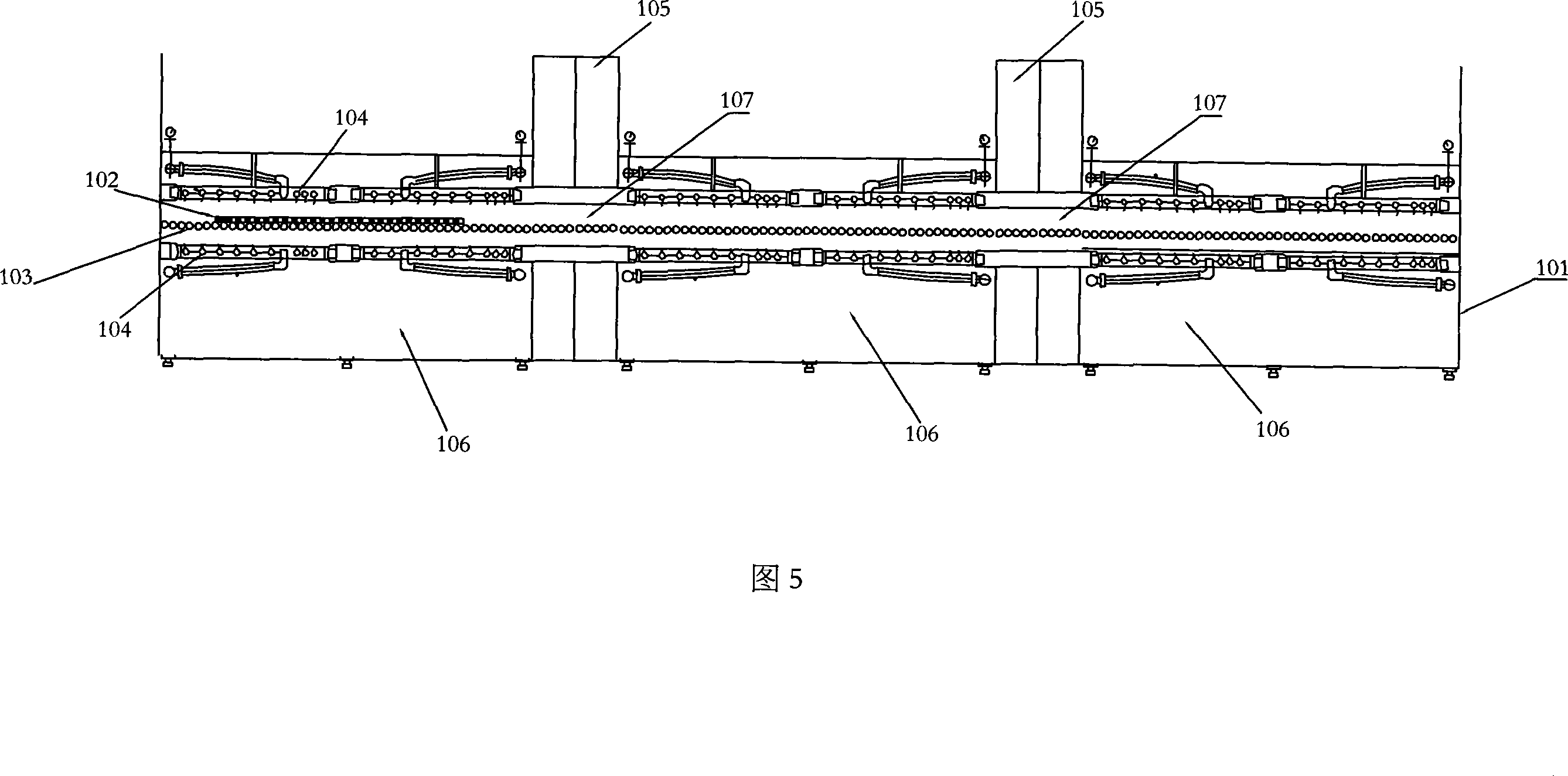

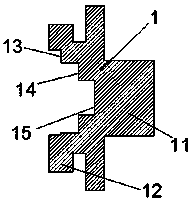

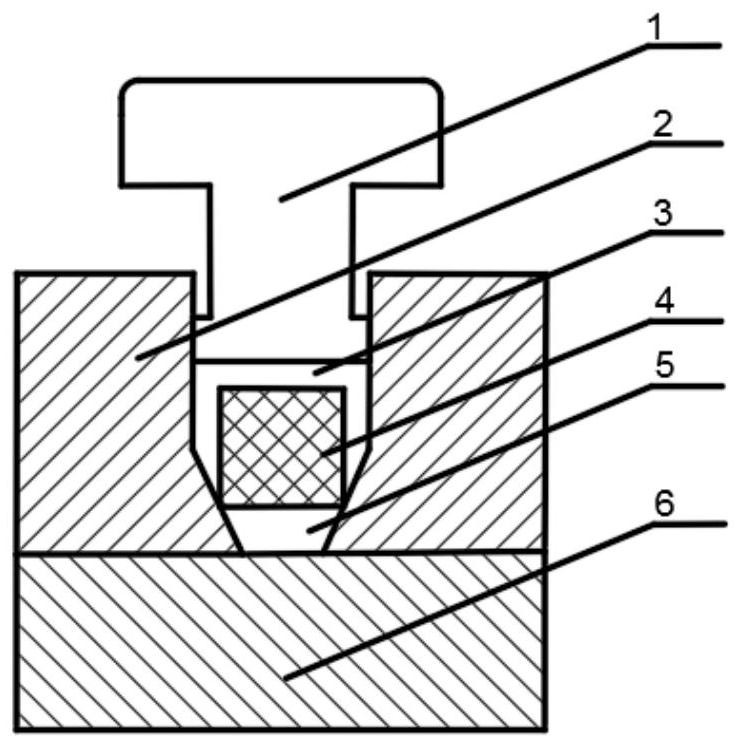

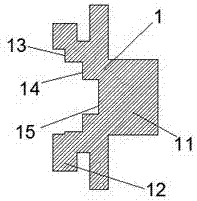

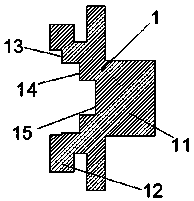

Sizing stand of main engine seat for manufacturing seamless steel tube

InactiveCN101049606AEasy to processEasy machining accuracyMetal rolling stand detailsMetal rolling arrangementsEngineeringMechanical engineering

A main machine base of a sizing mill for manufacturing seamless steel pipe features the existing C-shaped machine base is divided into lower machine base, upper transverse beam, supporting arch, and laterial supporters, and all of them are connected by the connecting parts to become a combined body.

Owner:TAIYUAN TONGZE HEAVY IND

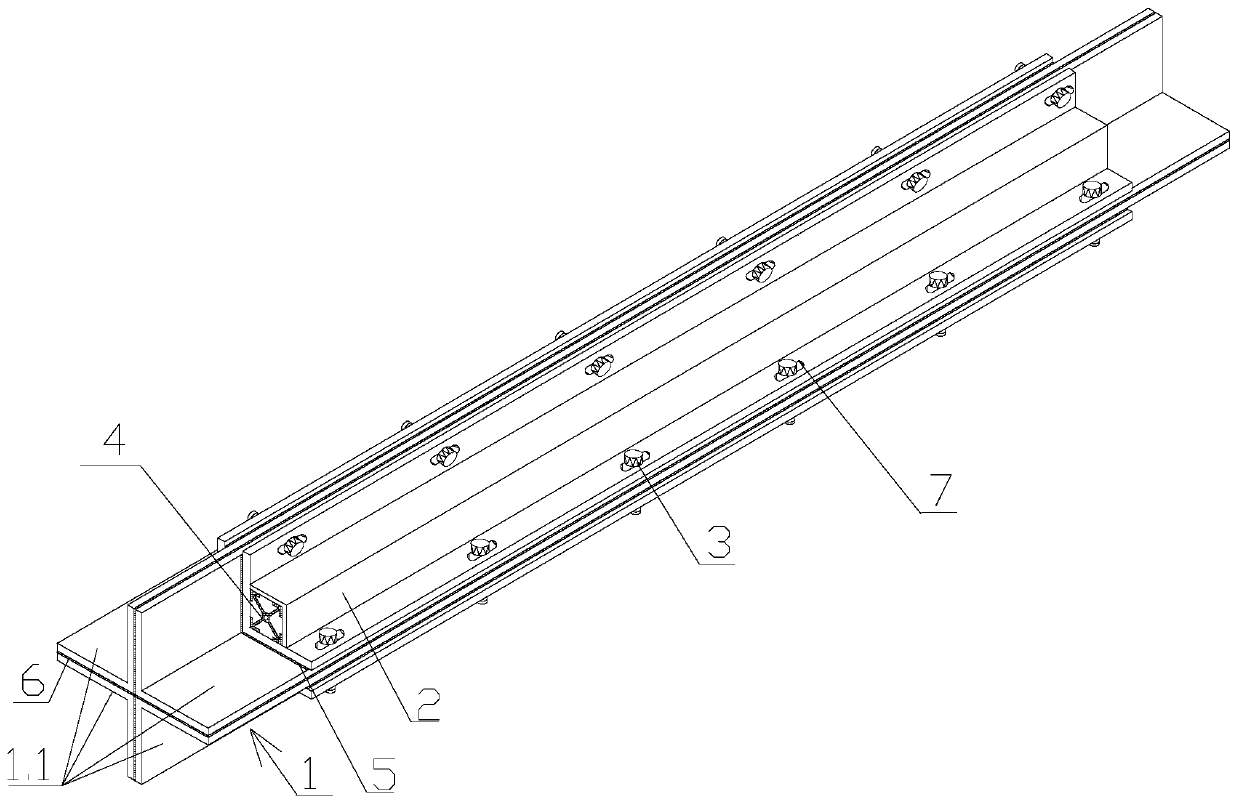

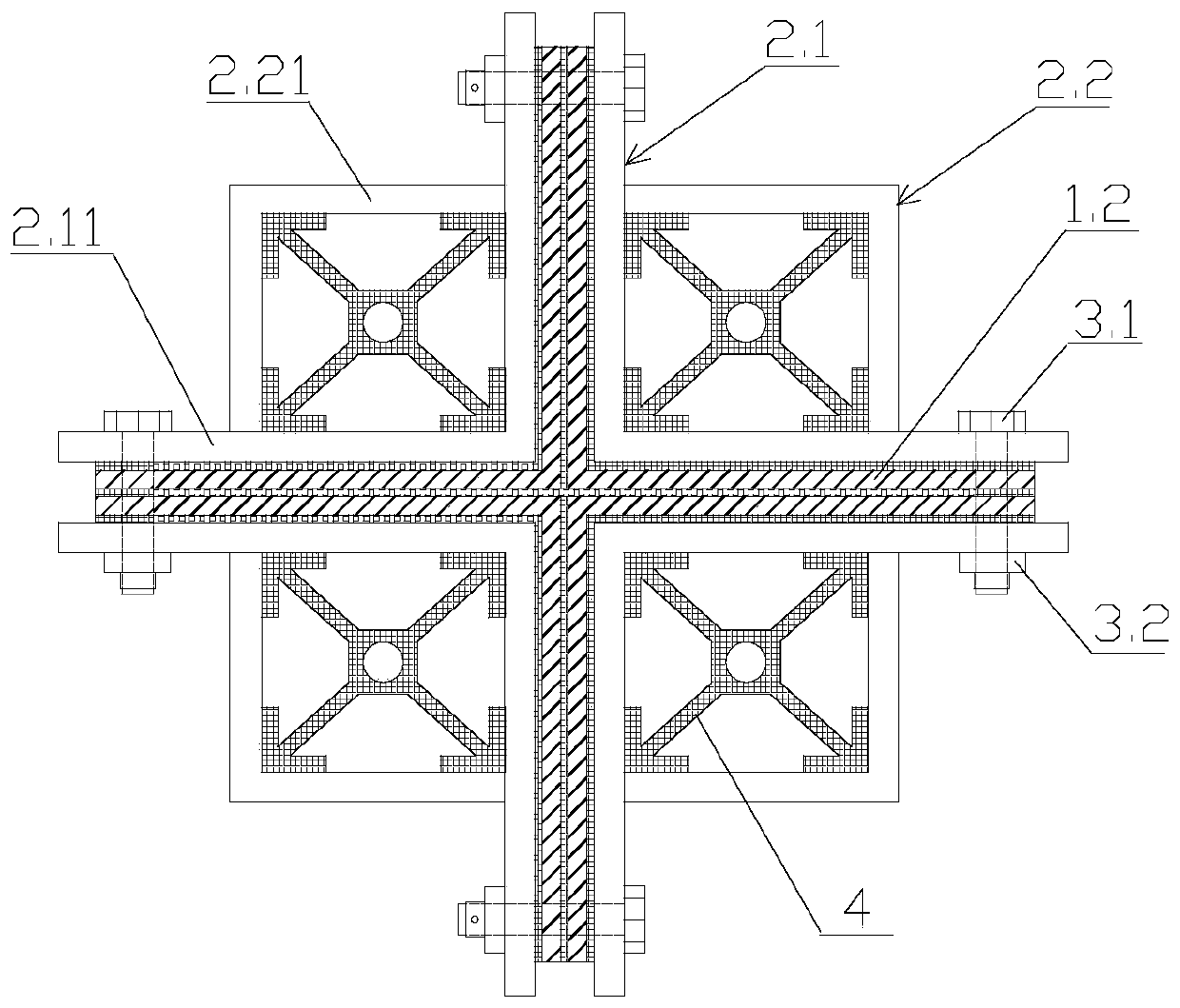

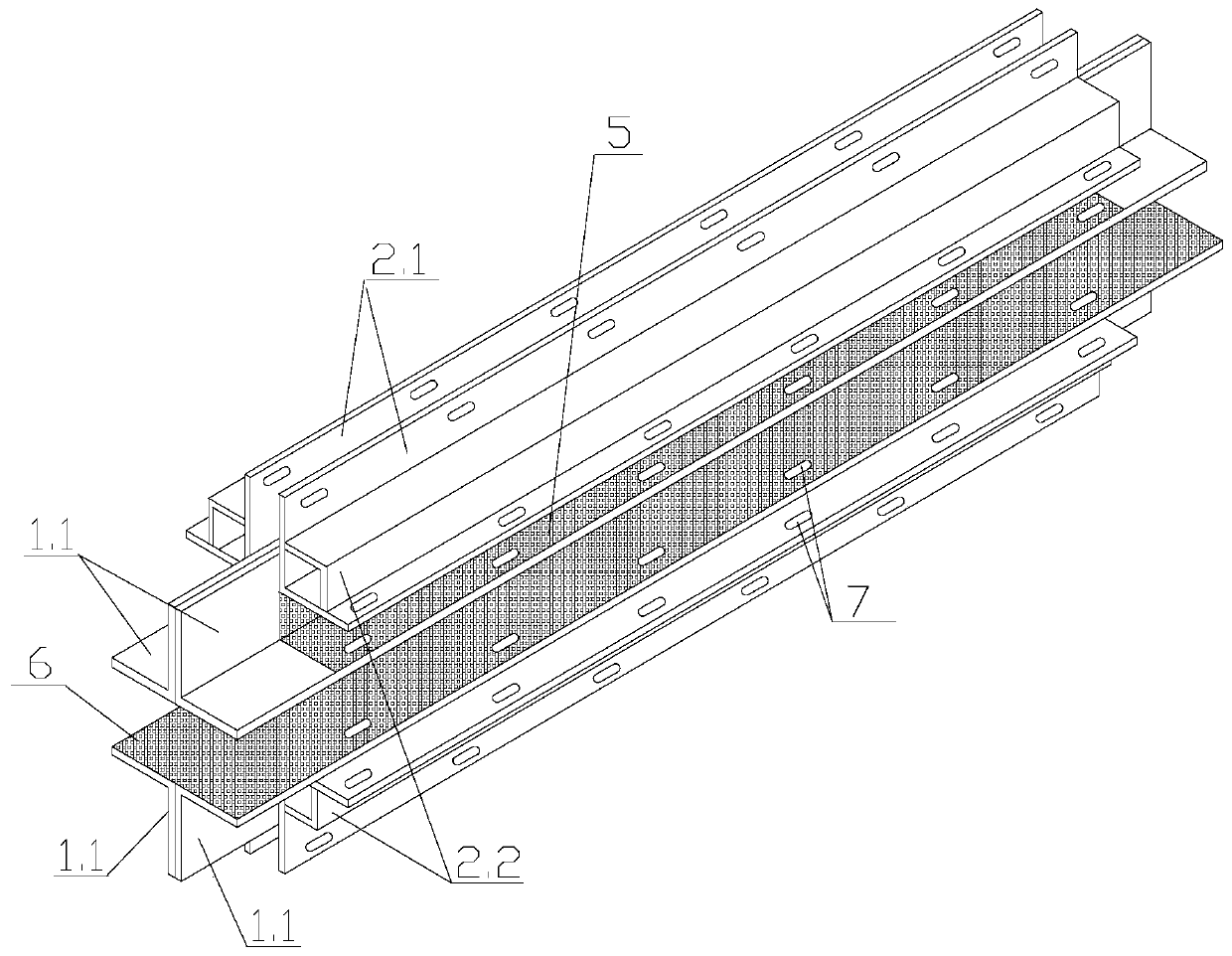

Crisscross section total-prefabricated-type anti-buckling supporting member

PendingCN111270898AImprove ductilityImprove energy consumptionProtective buildings/sheltersShock proofingEarthquake resistanceEngineering

The invention discloses a crisscross section total-prefabricated-type anti-buckling supporting member. The crisscross section total-prefabricated-type anti-buckling supporting member comprises a crosscore member located at the center and four constraint square steel tube assemblies which are correspondingly arranged in the four right angle corners of the cross core member to form a peripheral constraint unit, the edges of every two adjacent constraint square steel tube assemblies are fixedly connected with a wing plate of the cross core member clamped between the two adjacent constraint square steel tube assemblies through a bolt assembly, and an X-shaped steel internal bracing is embedded in the tube of each constraint square steel tube assembly. According to the crisscross section total-prefabricated-type anti-buckling supporting member, the field assembly of all steel members is adopted, the construction is convenient, the manufacturing precision is easy to control, large tonnage buckling proof supporting can be improved through the arrangement of cross double cores, the precision control between a peripheral restraint member and a core steel plate is more convenient and concise, field installation is facilitated, all steel members can be manufactured in a factory, and the processing precision is easy to control; and the ductility performance of the member is obviously improved, the energy consumption capacity is greatly improved, and the seismic performance is improved.

Owner:TIANJIN UNIV RENAI COLLEGE

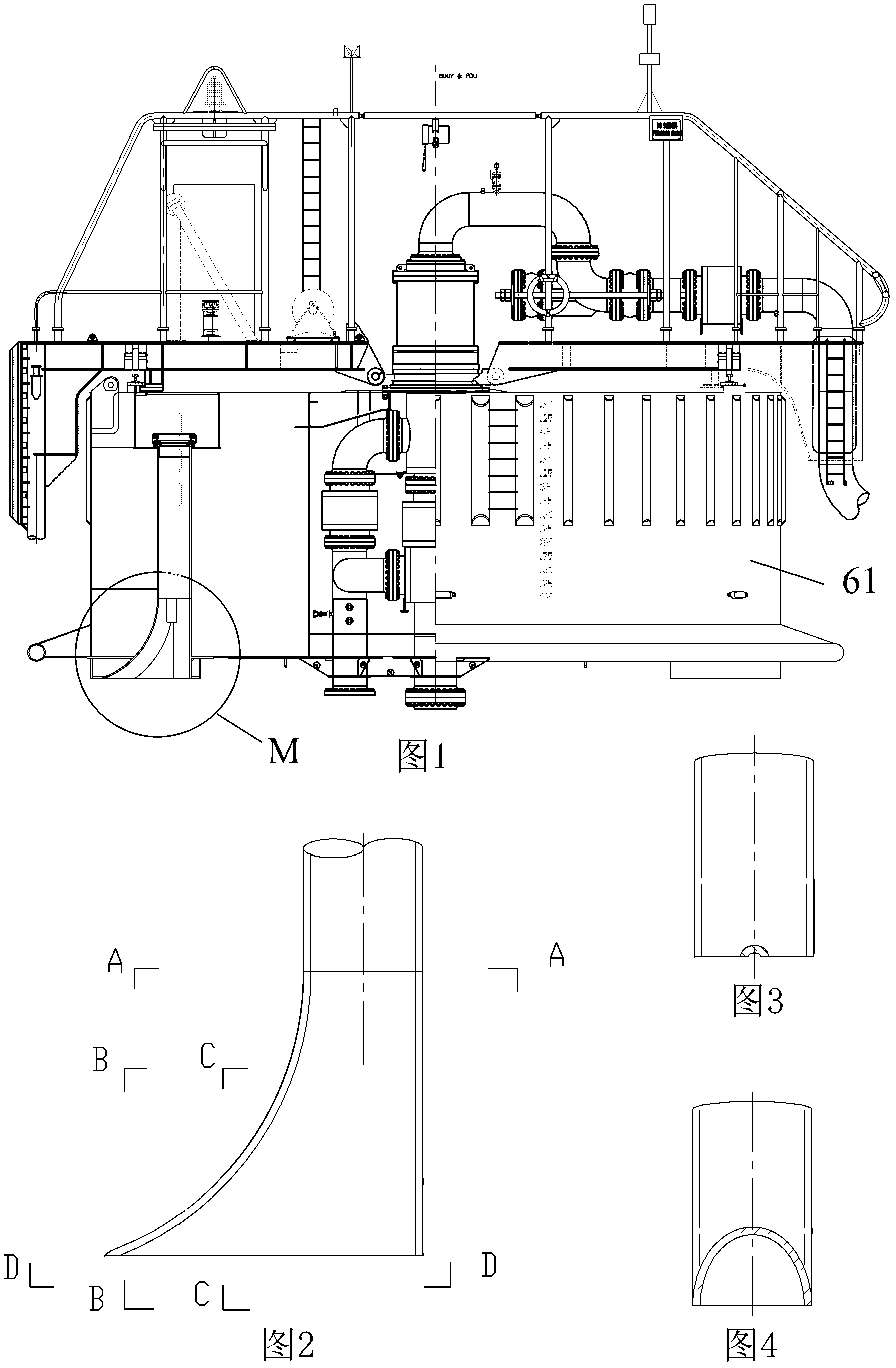

Making method of hawsepipe for single point mooring buoy main body

The invention discloses a making method of a hawsepipe for a single point mooring buoy main body. The hawsepipe comprises an upper cylinder and a lower saddle-shaped structure, wherein the saddle-shaped structure comprises a semi-straight pipe as well as a triangular plate with an arc and a bent pipe, wherein the semi-straight pipe is positioned on a half side; the triangular plate with the arc and the bent pipe are positioned on the other half side and spliced with the side end surface of the semi-straight pipe; the lower part of the saddle-shaped structure is horizontally embedded with an embedding bottom plate and an embedding plate in parallel; and the lower part of the saddle-shaped structure is additionally provided with reinforcing ribs and an enclosure plate. Transitional circular arc plates are also arranged on two sides of the upper part of the saddle-shaped structure. Through designing a machining process, the making method of the hawsepipe for the single point mooring buoy main body, disclosed by the invention, has the advantages that errors are reduced and the machining precision is enhanced because a hawsepipe structure is formed; and the invention integrally provides the simple and convenient method with high machining quality and low machining cost.

Owner:DALIAN SHIPBUILDING IND

Linear dispersion combined prism optical splitter

The invention discloses a linear dispersion combined prism optical splitter. The linear dispersion combined prism optical splitter is formed by combining two prisms which are manufactured from special materials and coated with films on the side surfaces by a mode of enabling the bottom surfaces to be clung to each other and the film-coated surfaces to be opposite to each other. The linear dispersion combined prism optical splitter is particularly suitable for the fields of spectrum analysis, spectrum detection and related fields. The linear dispersion combined prism optical splitter is on the basis of the control variable method and differential equation concept; the spreading direction of the line and the shape of the prisms are controlled according to the dispersion property of the first prism material; the nonlinear dispersion of the first prism is compensated according to the nonlinear dispersion of the second prism so as to obtain the linear dispersion combined prism optical splitter. The linear dispersion combined prism optical splitter can overcome the defect of nonlinear dispersion of single prism and has the advantages of being wide in free spectrum range, high in light energy utilization rate, high in generality, simple in structure, and small in cost.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Deep hole processing tool structure

InactiveCN101850520AEasy assemblyReasonable structurePositioning apparatusMetal-working holdersDeep holeFlange

The invention relates to a deep hole processing tool structure, which is characterized in that: a first positioning sleeve, a second positioning sleeve and a first flange cover are fastened to a processed surface at a position of a first fixing shaft of a box through screws; a first space ring, a second positioning plate and a second space ring are sequentially arranged between the second positioning sleeve and the first flange cover; a first positioning plate is arranged on the first fixing shaft between the first positioning sleeve and the second positioning sleeve in a floating mode; a second fixing shaft is parallel to the first fixing shaft and connected with a second flange cover through a screw; and a pad is arranged behind the first positioning plate and locked by a lock nut in a thread mode and fixes the axial position of the first positioning plate. The structure has the advantages of effectively providing support for a boring shaft, providing effective guarantee for links such as the processing of the box and the assembly of products, facilitating reducing the assembly difficulty, improving the processing efficiency of the products, ensuring the quality of the products,along with simple processing and assembly and reasonableness.

Owner:无锡桥联数控机床有限公司

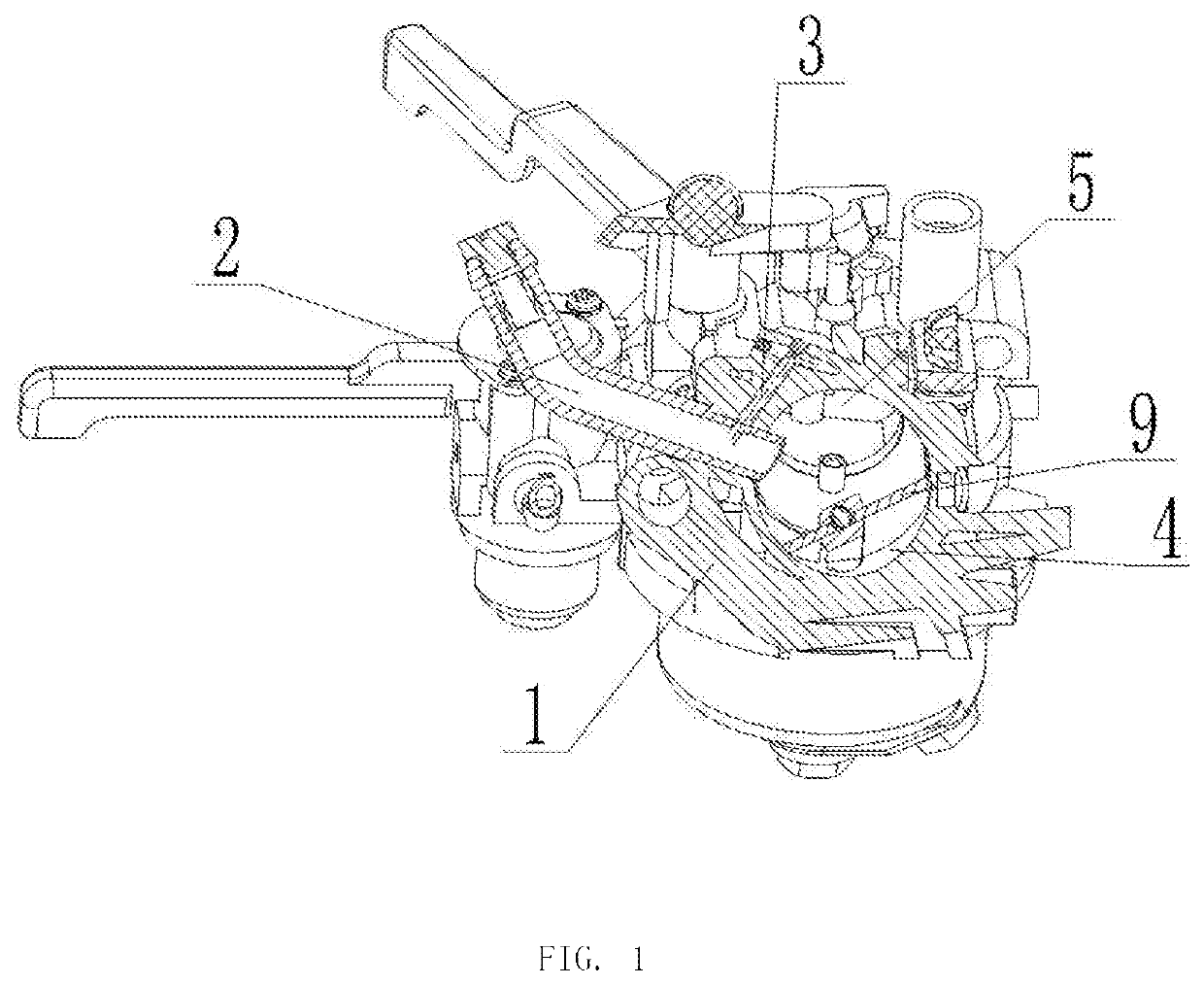

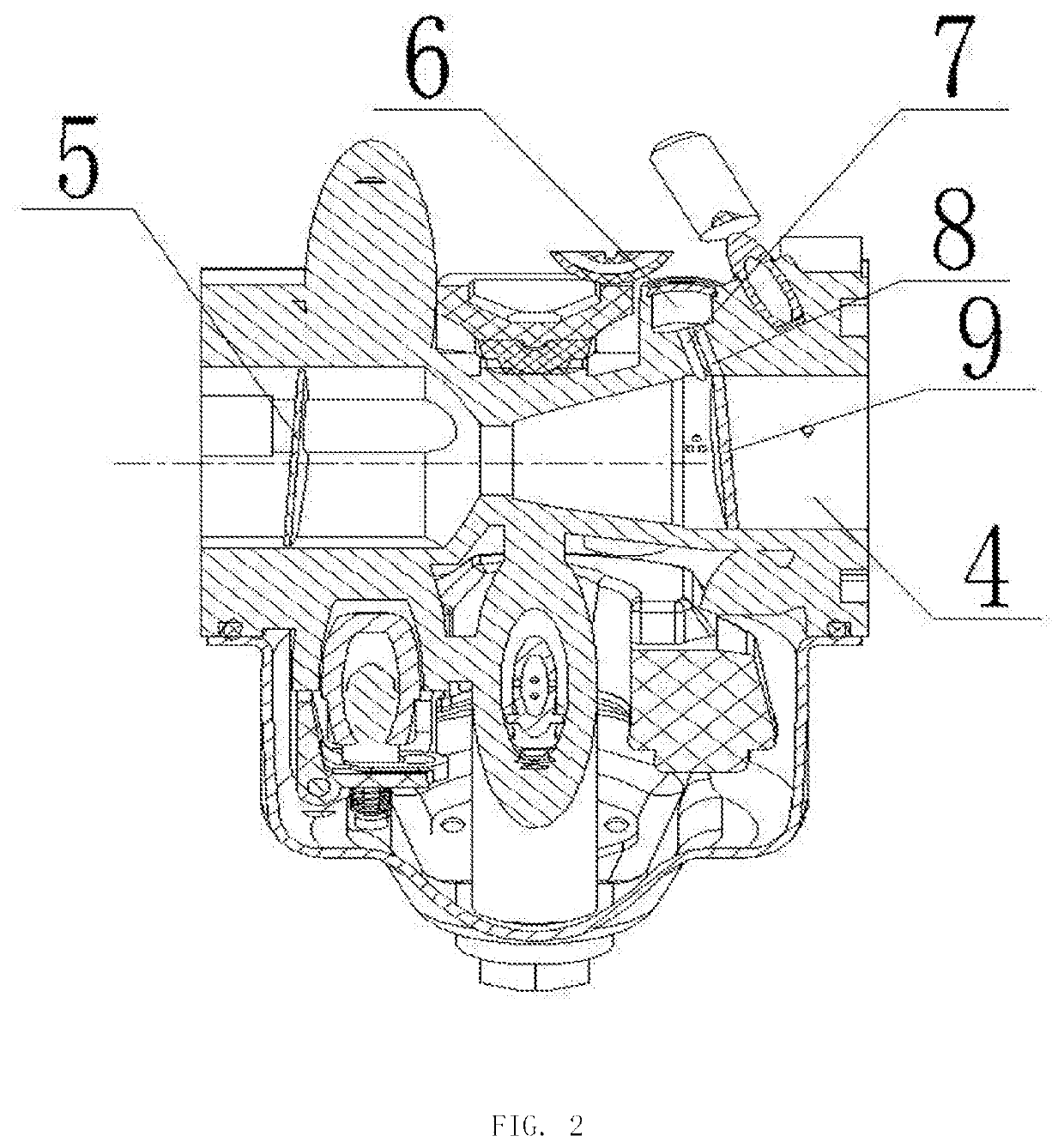

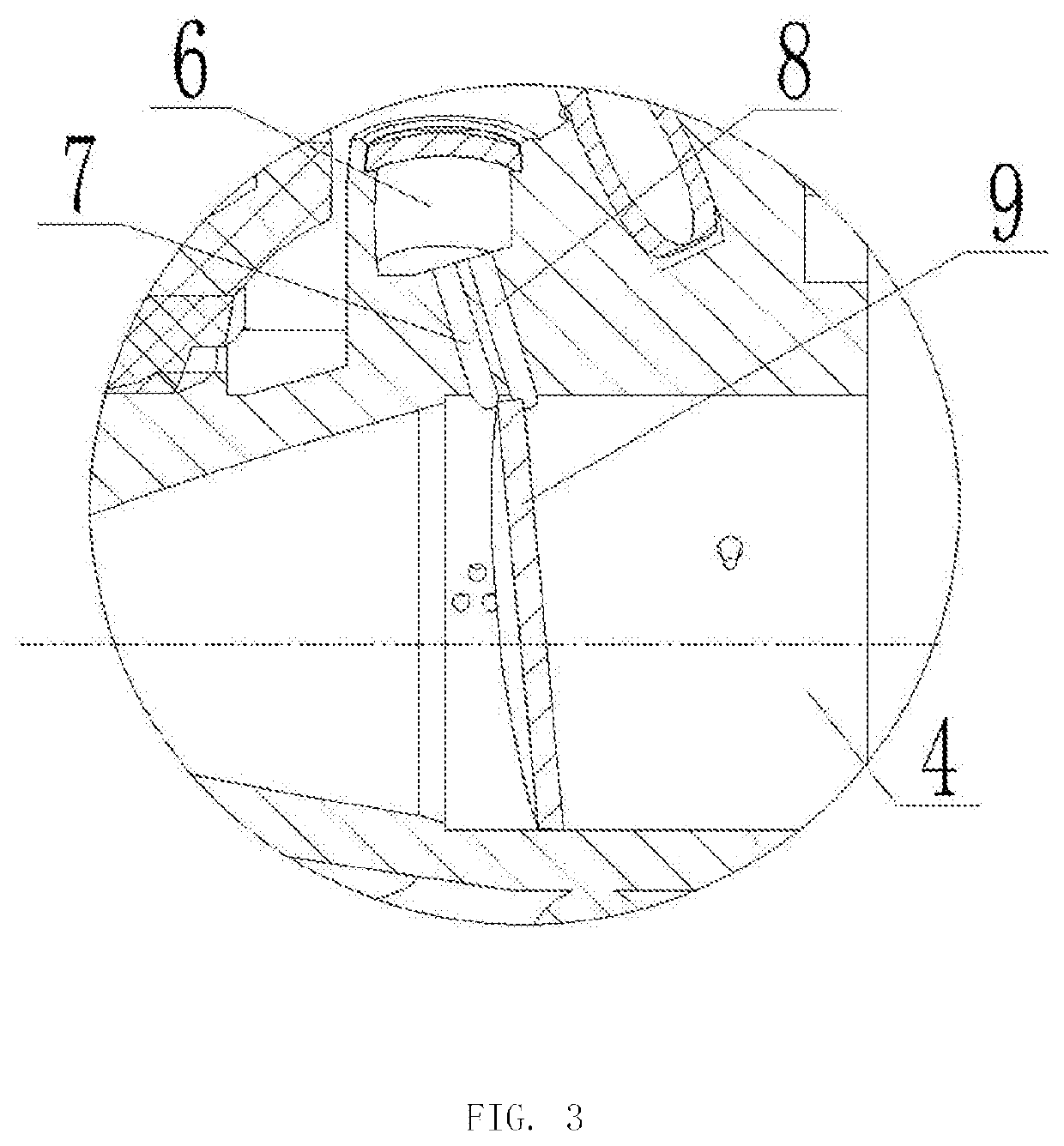

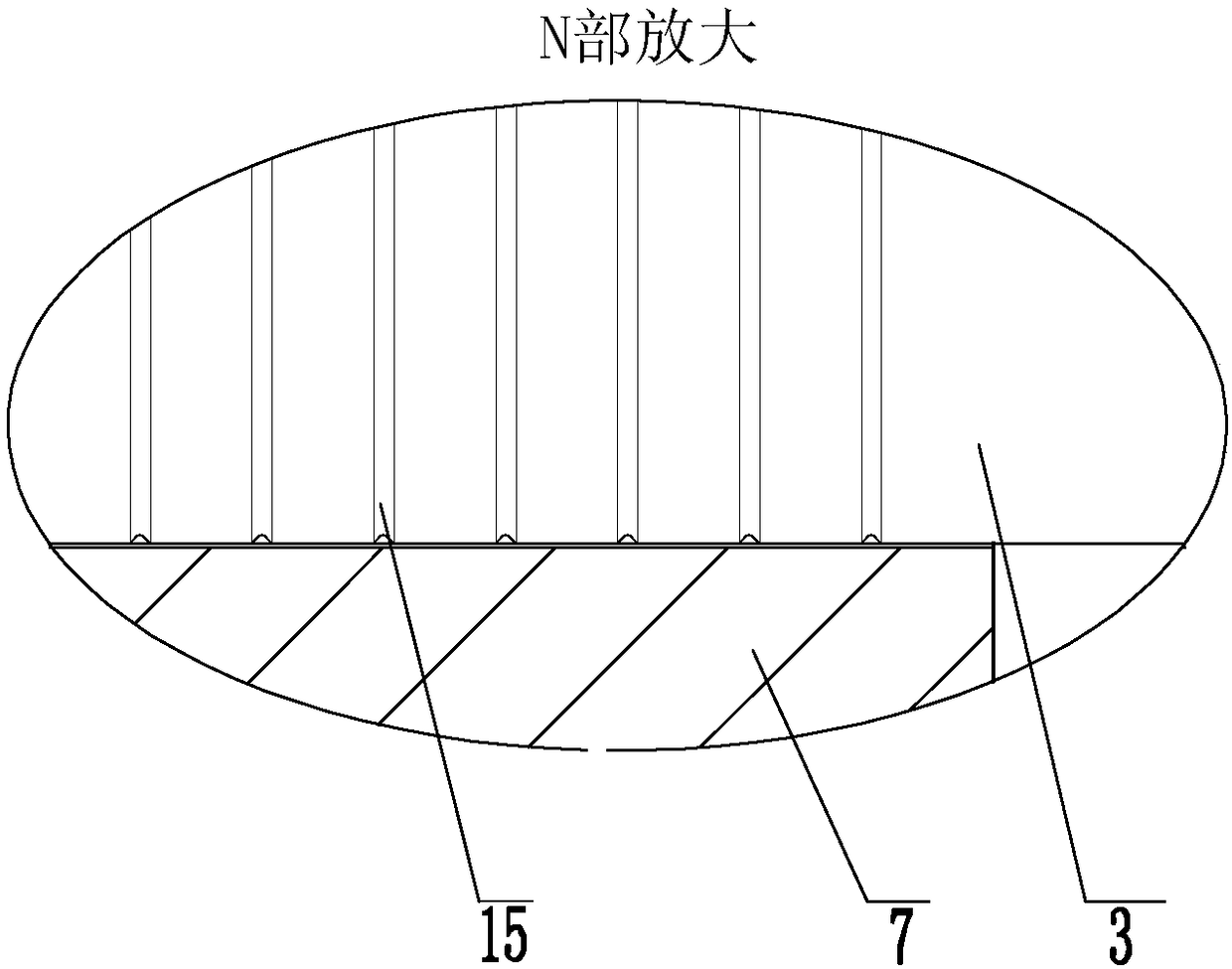

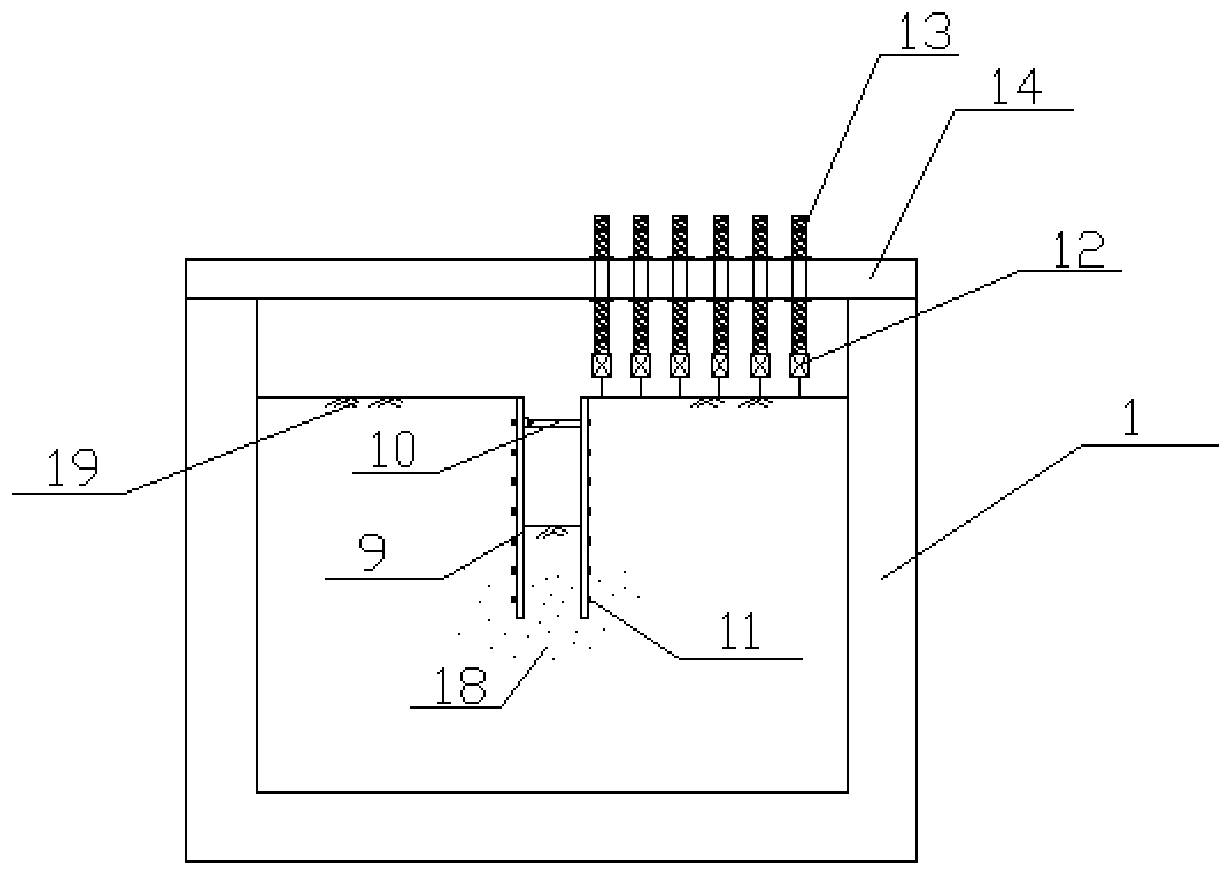

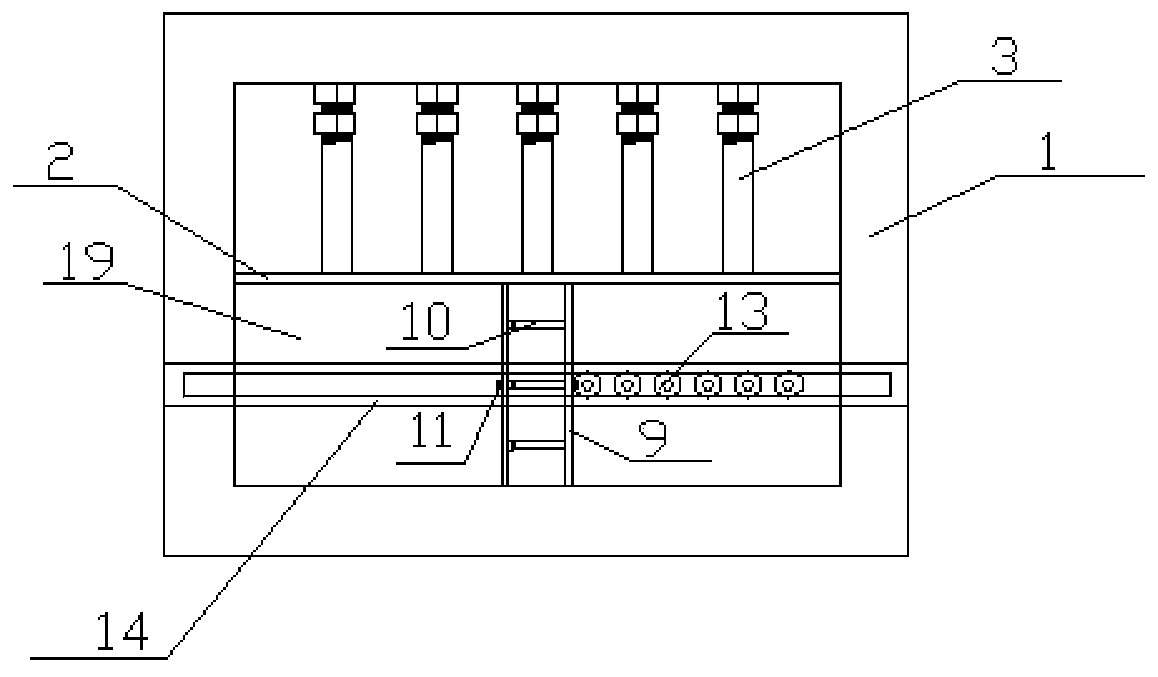

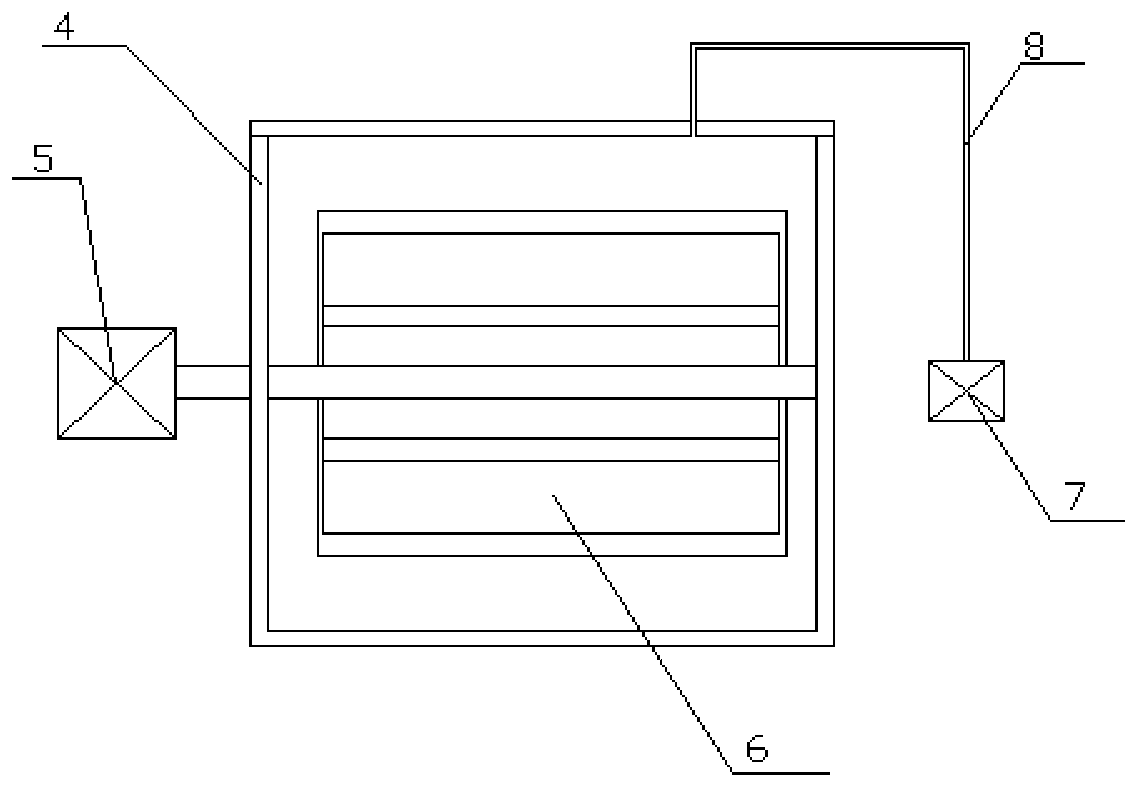

Gas idling transition passage structure for oil and gas dual-purpose carburetor

ActiveUS11193451B2Solve the real problemImprove controllabilityMachines/enginesCarburettorsEngineeringCarburetor

The utility model provides a gas idling transition passage structure for oil and gas dual-purpose carburetor, comprising a carburetor body 1 and a mixing chamber 4; a choke valve 5 and a throttle valve 9 are disposed in the mixing chamber 4 in the order of the air flow direction; a gas intake pipe 2 for supplying gas to the mixing chamber 4 is disposed on the carburetor body 1; a first air inlet pipe 7 and a second air inlet pipe 8 are disposed in the carburetor body 1 in parallel; an opening of an outlet end of the second air inlet pipe 8 is located in the mixing chamber 4 and the position of the outlet end of the second air inlet pipe 8 is at the intersection of an outer circle and the mixing chamber 4 when the throttle valve 9 is closed.

Owner:CHEN QIAN

Deep hole processing tool structure

InactiveCN101850520BDoes not affect machining accuracyDoes not affect assemblyPositioning apparatusMetal-working holdersPositioning systemFlange

The invention relates to a deep hole processing tool structure, which is characterized in that: a first positioning sleeve, a second positioning sleeve and a first flange cover are fastened to a processed surface at a position of a first fixing shaft of a box through screws; a first space ring, a second positioning plate and a second space ring are sequentially arranged between the second positioning sleeve and the first flange cover; a first positioning plate is arranged on the first fixing shaft between the first positioning sleeve and the second positioning sleeve in a floating mode; a second fixing shaft is parallel to the first fixing shaft and connected with a second flange cover through a screw; and a pad is arranged behind the first positioning plate and locked by a lock nut in a thread mode and fixes the axial position of the first positioning plate. The structure has the advantages of effectively providing support for a boring shaft, providing effective guarantee for links such as the processing of the box and the assembly of products, facilitating reducing the assembly difficulty, improving the processing efficiency of the products, ensuring the quality of the products,along with simple processing and assembly and reasonableness.

Owner:无锡桥联数控机床有限公司

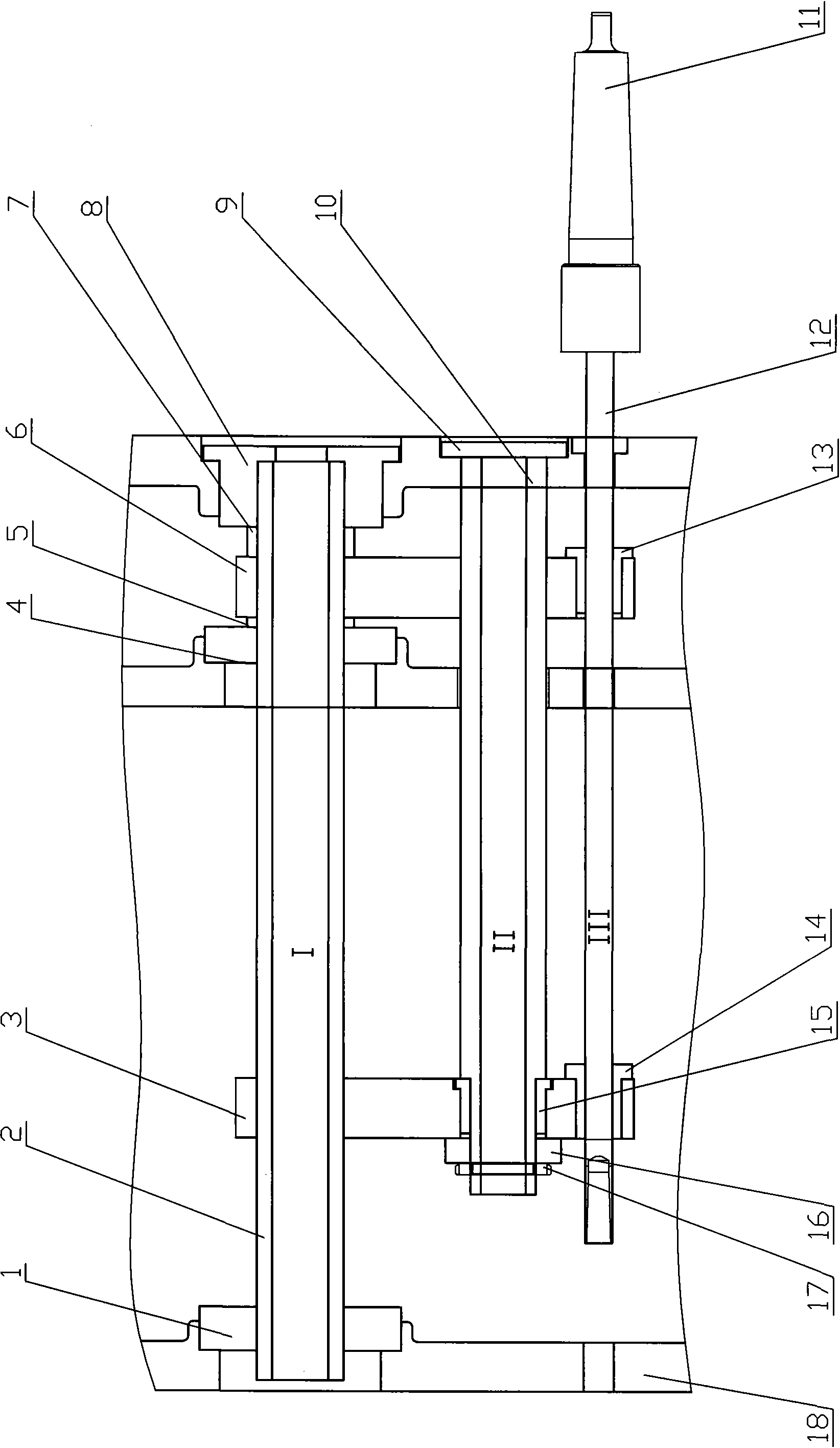

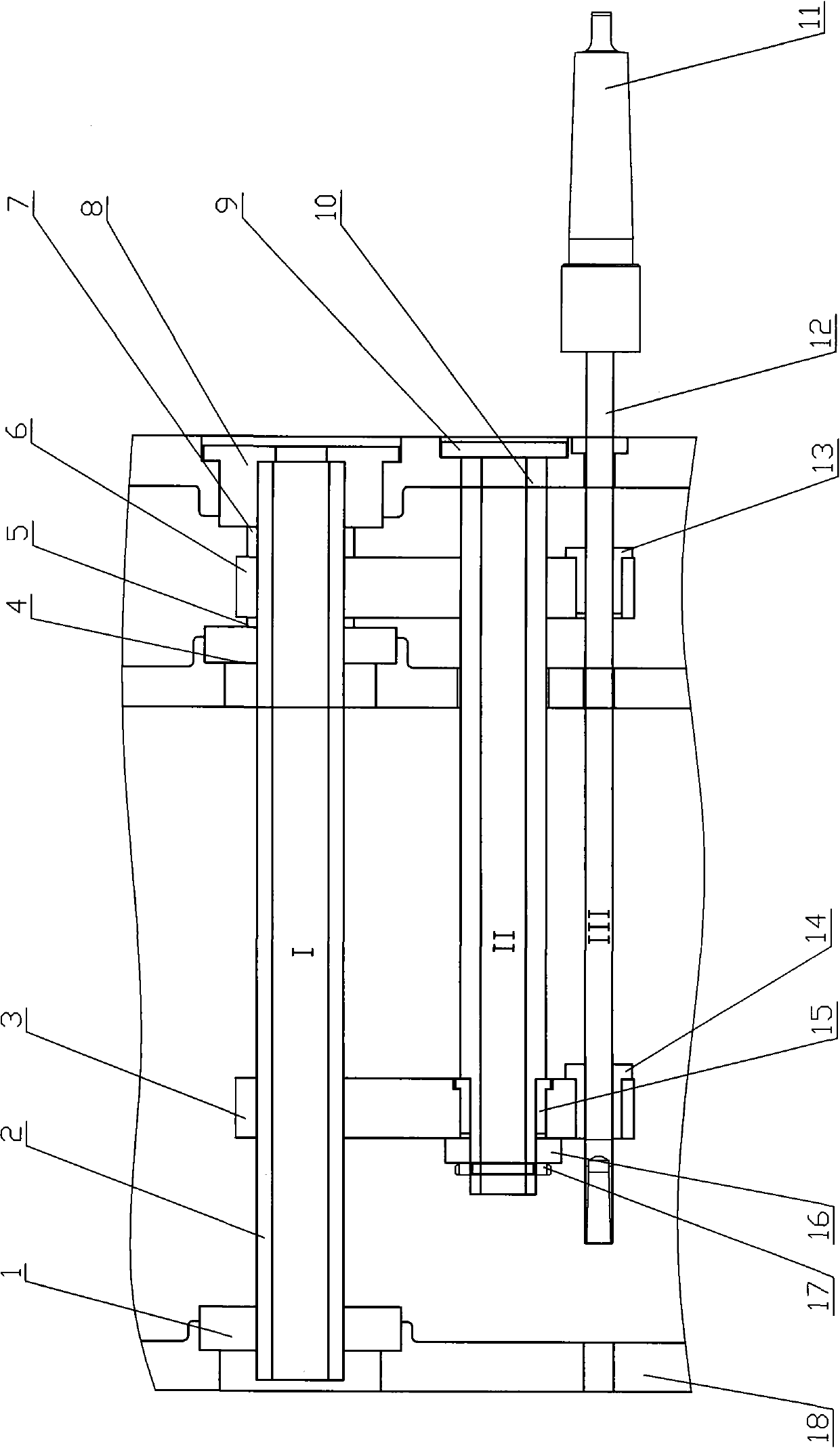

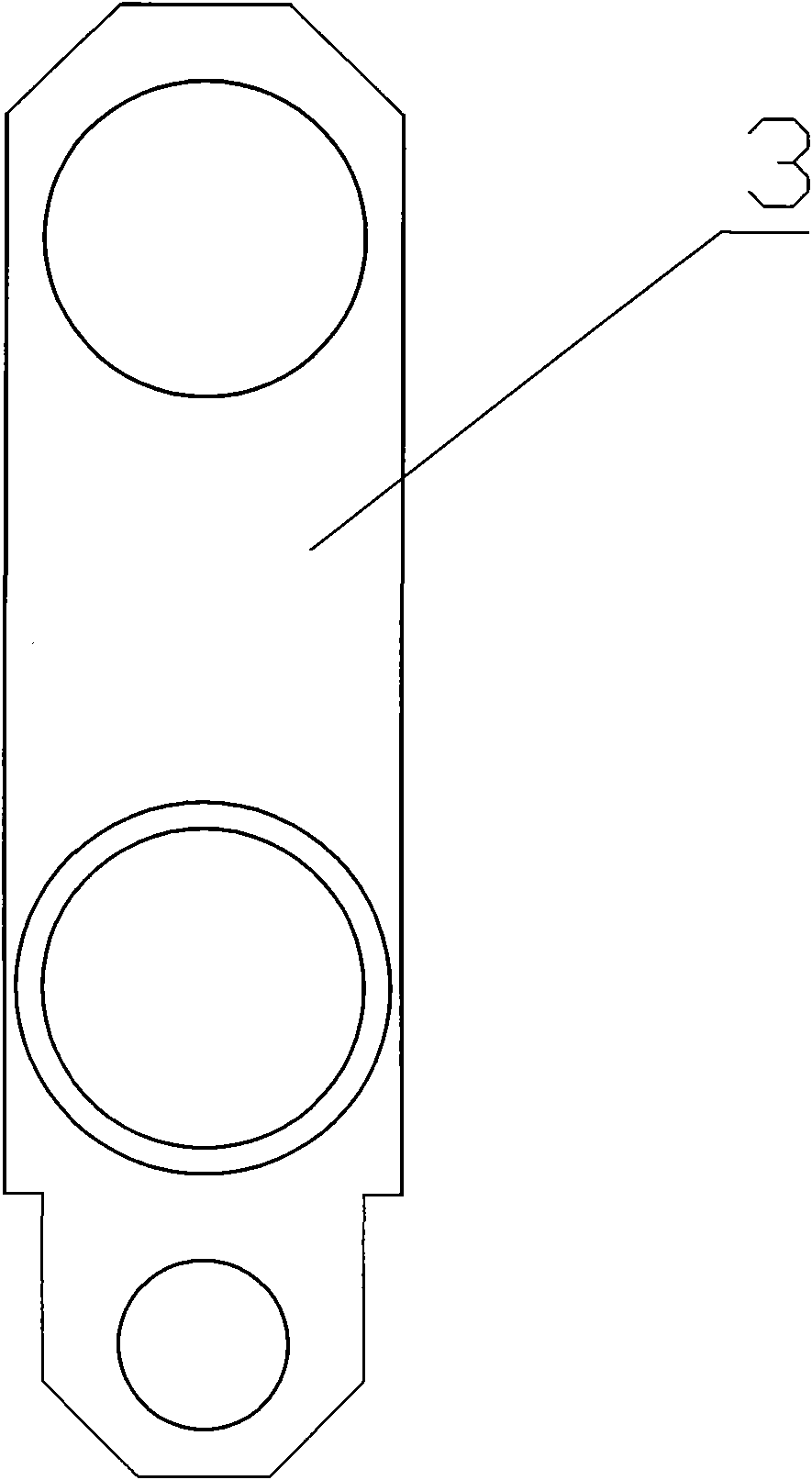

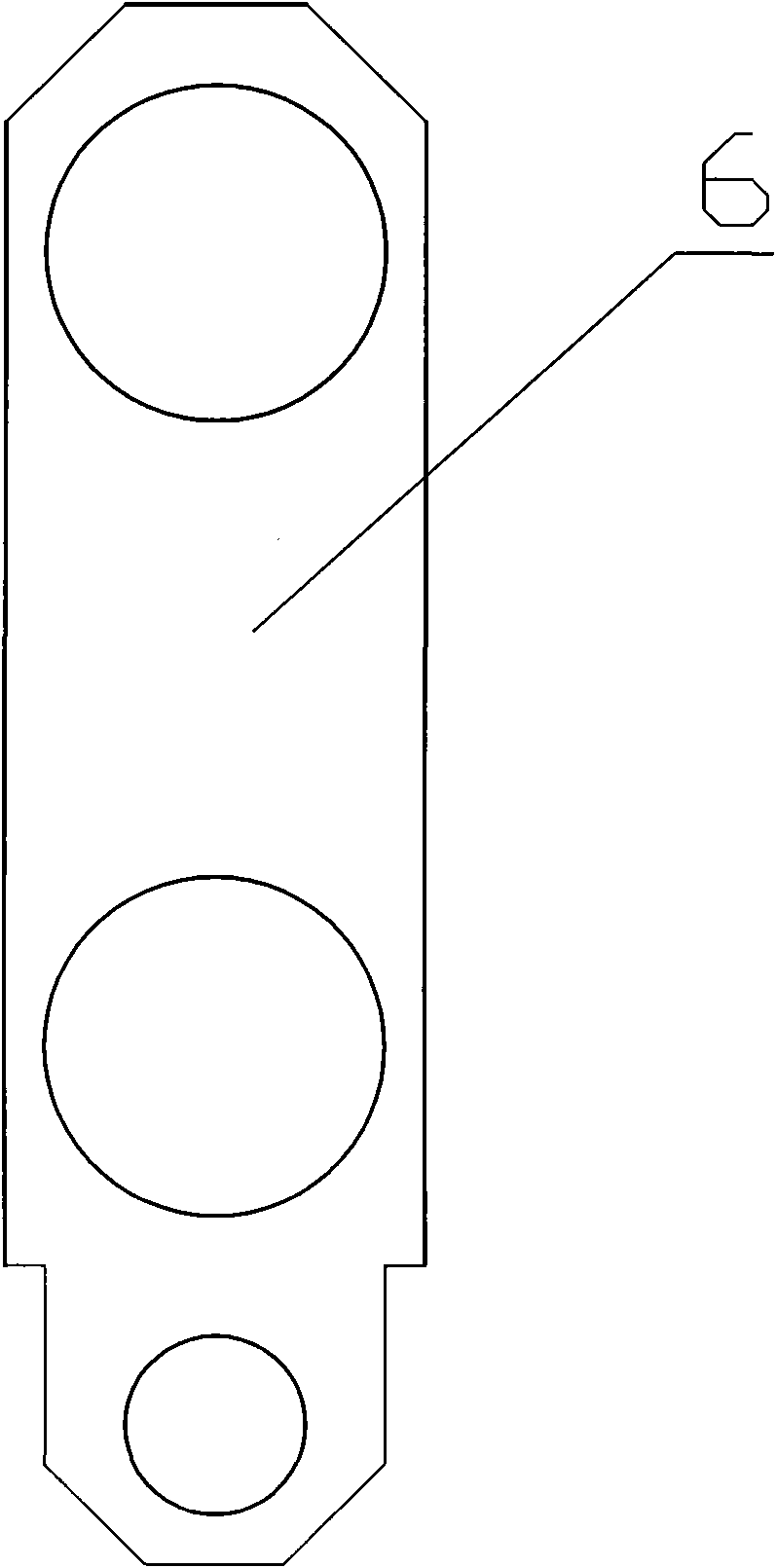

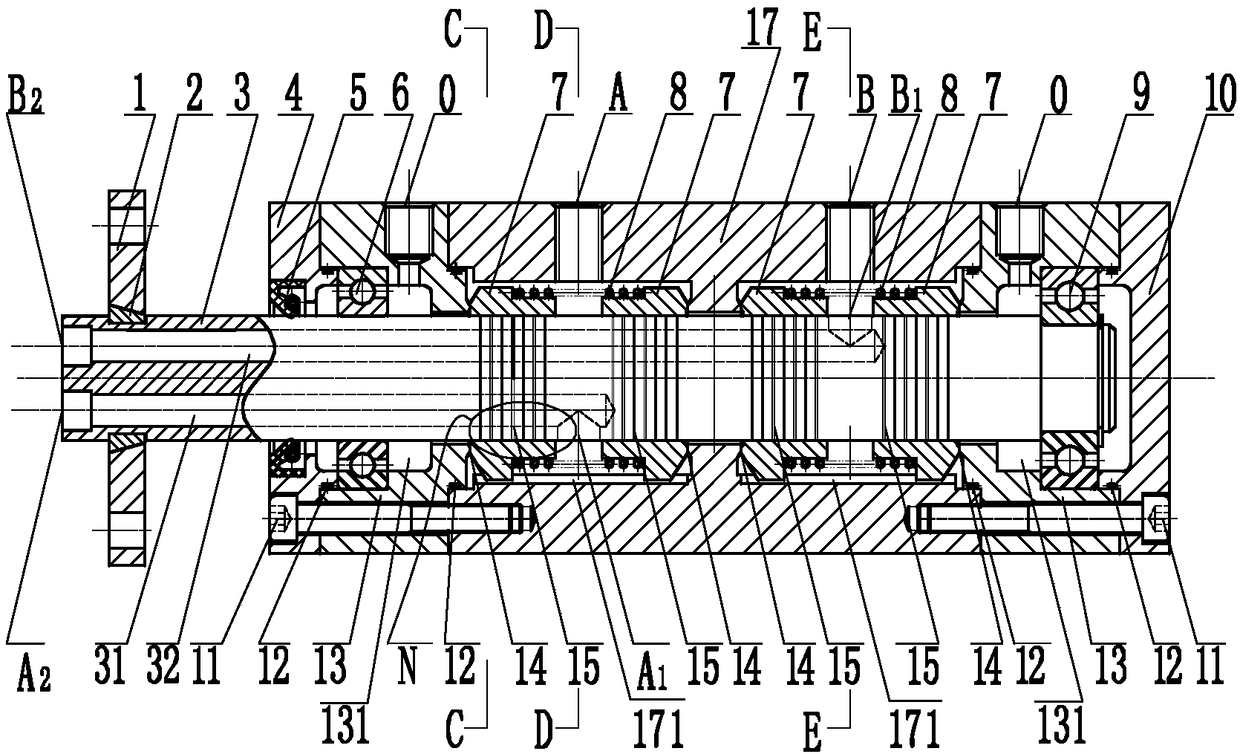

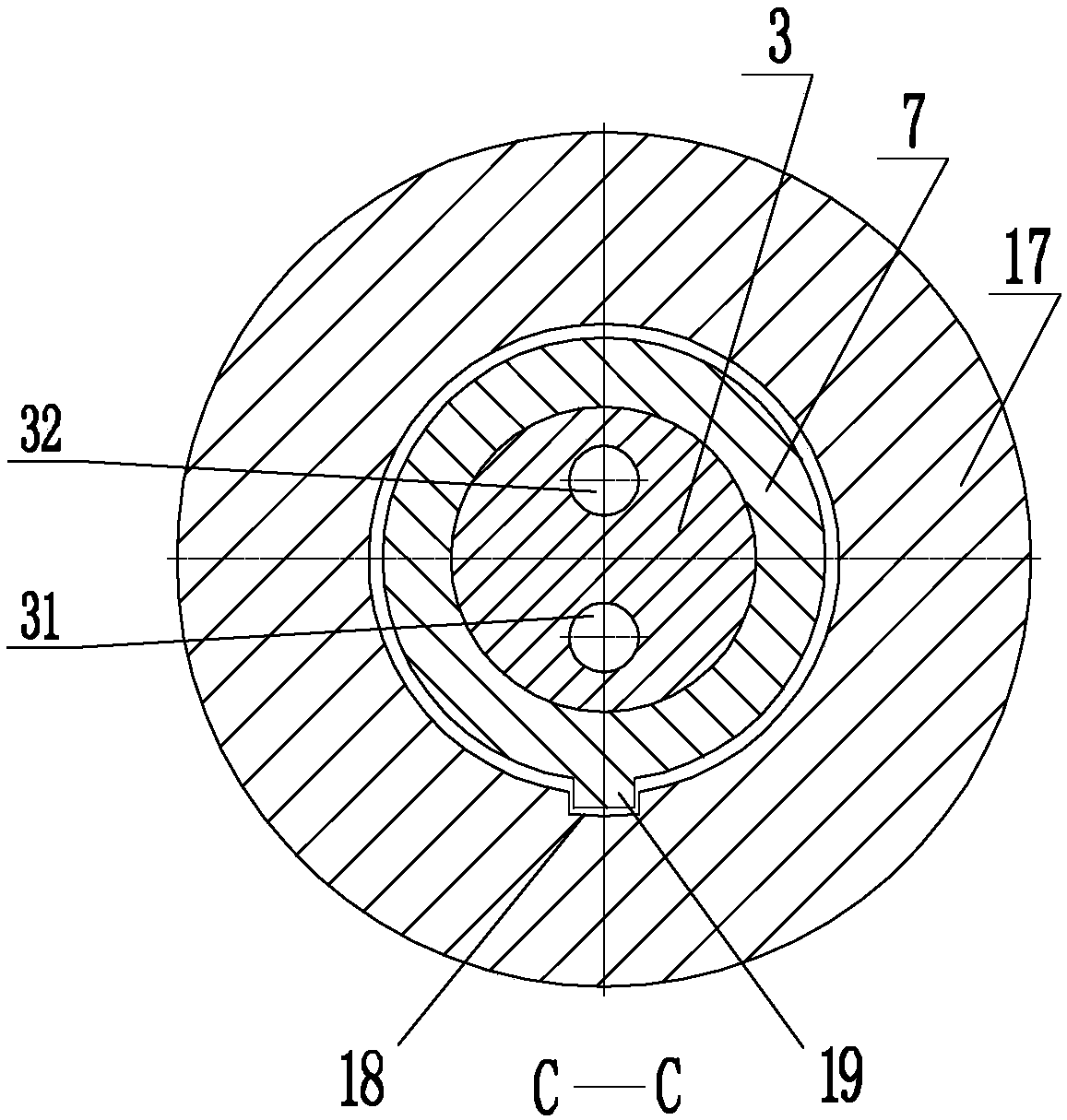

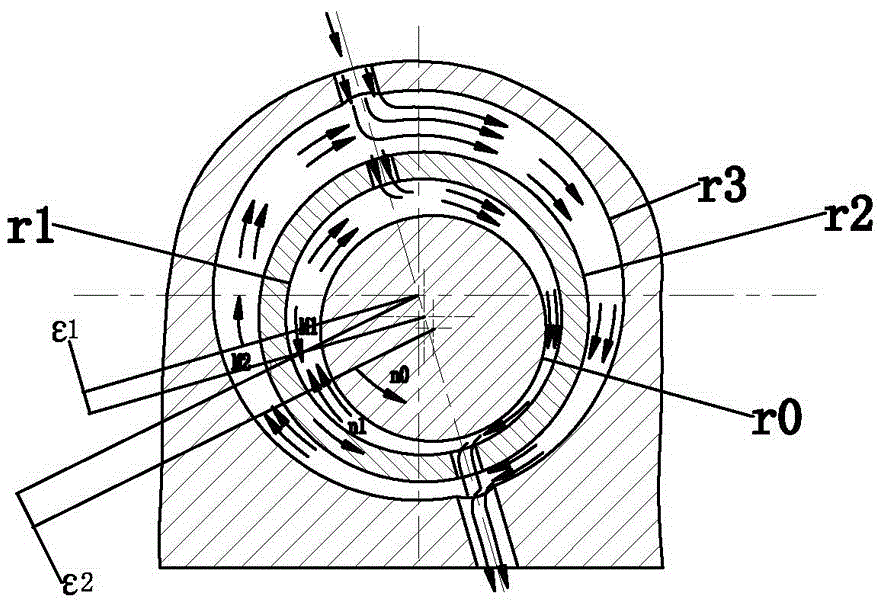

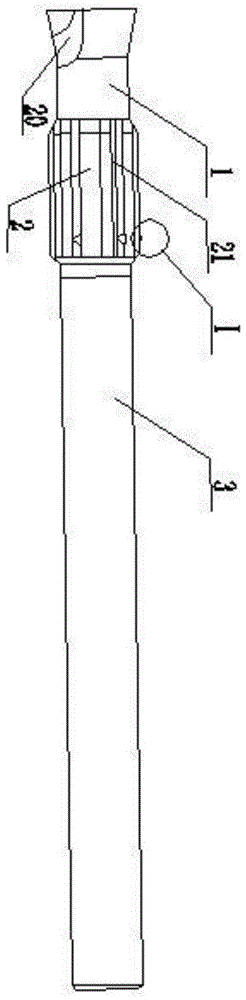

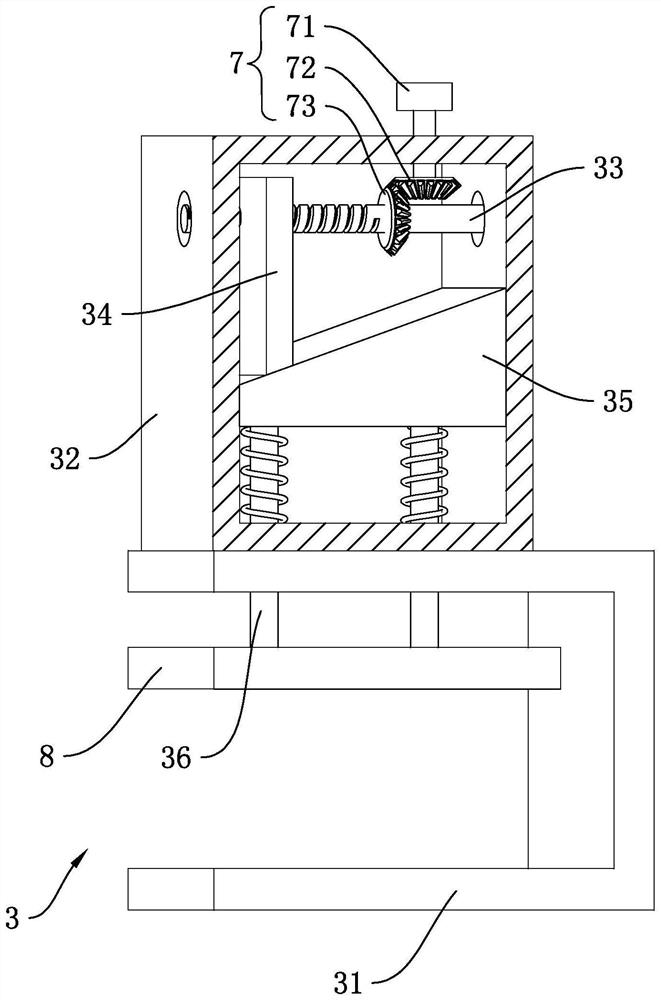

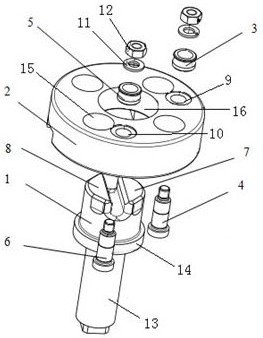

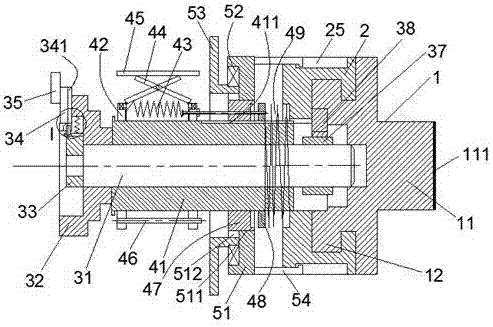

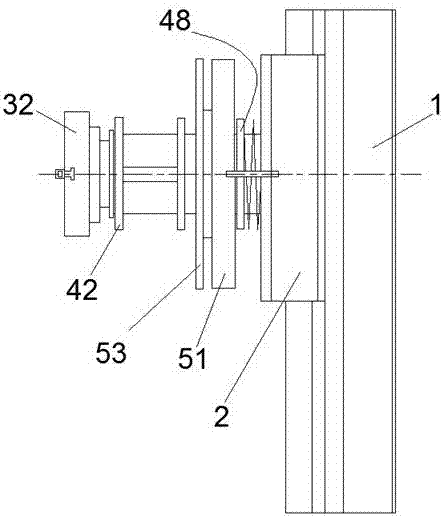

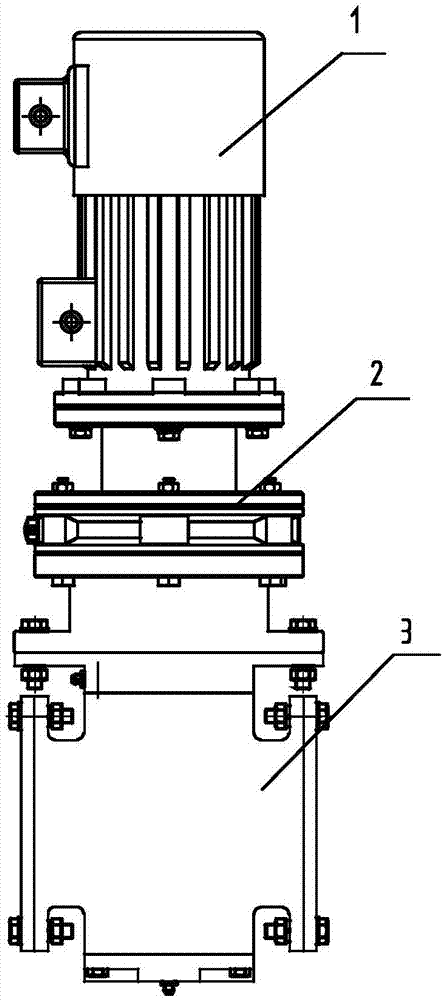

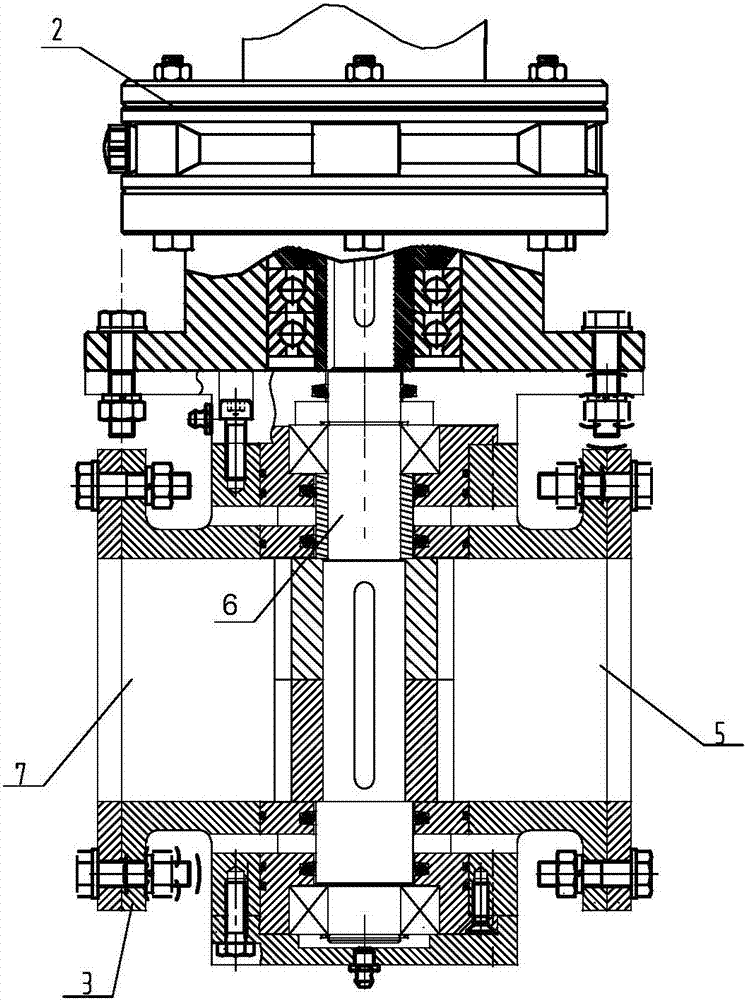

A rotary liquid supply device

ActiveCN106931262BShorten the lengthEasy machining accuracyEngine sealsPipe elementsRotational axisEngineering

The invention belongs to the technical field of rotating liquid supply and relates to a rotating liquid supply device. Bearing bases are connected to the two ends of a barrel body correspondingly. A bearing is installed on each bearing base. A rotating shaft is supported on the bearings. A sealing end cover is arranged at the outer ends of each bearing base and the corresponding bearing. Two axial liquid guiding holes are formed in the rotating shaft in parallel. Each liquid guiding hole is provided with a radial liquid passing opening. Two annular grooves are formed in the barrel body in a spaced mode. Each annular groove is internally sleeved with two floating sleeves. A spring is supported between the two floating sleeves in each annular groove. A radial liquid passing hole is formed in each annular groove. Each liquid passing hole communicates with the corresponding liquid passing opening. The floating sleeves and the barrel body are circumferentially positioned. Sealing rings are arranged between the barrel body and the bearing bases as well as between the bearing bases and the sealing end covers. A liquid collecting cavity is formed in the inner side of each bearing. Each bearing base is provided with a radial liquid drainage hole communicating with the corresponding liquid collecting cavity. The rotating liquid supply device is suitable for rotating shaft liquid passing hole liquid pressure conveying.

Owner:张嗣远

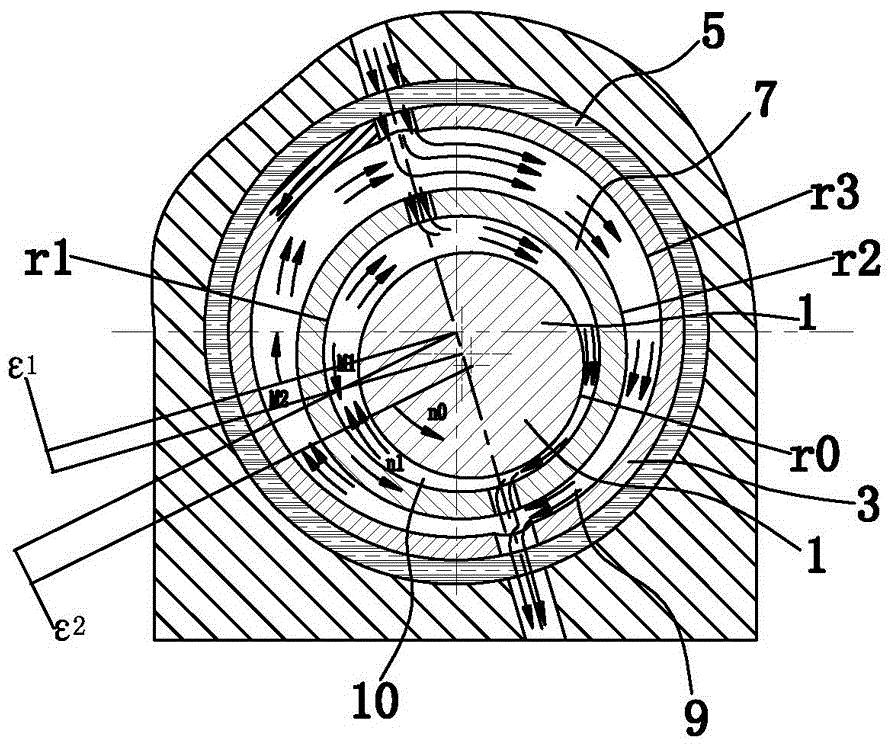

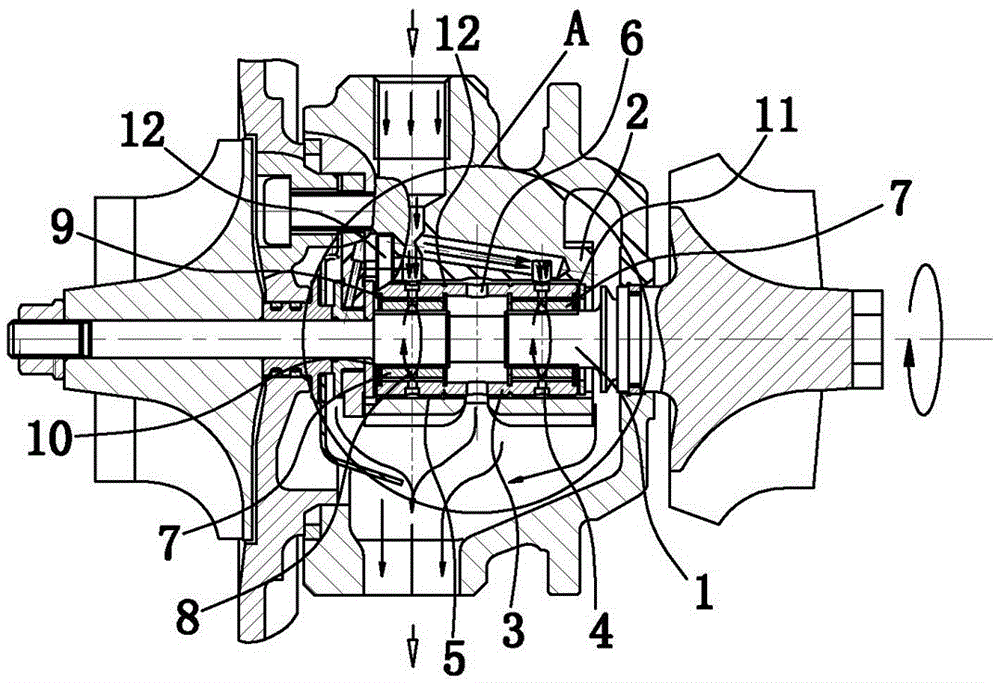

A floating bearing structure for small turbocharger

ActiveCN104132066BStructure miniaturizationLow mass of rotational inertiaShaftsBearing componentsSelf excitedTurbocharger

The invention provides a floating bearing structure used for small turbochargers, and belongs to the technical field of machines. The problems of low efficiency, easy self-excited vibration, low durability and low stability of present bearing structures used for turbochargers. The floating bearing structure used for small turbochargers comprises a single semi-floating bearing sleeve, the single semi-floating bearing sleeve is provided with a plurality of oil holes I, a static oil clearance exists between the single semi-floating bearing sleeve and a bearing body, the single semi-floating bearing sleeve is provided with an oil return hole, a turbine rotating shaft is sheathed with a full-floating bearing sleeve, the full-floating bearing sleeve and the single semi-floating bearing sleeve are axially positioned, the full-floating bearing sleeve is provided with a plurality of oil holes II, a dynamic oil clearance I exists between the full-floating bearing sleeve and the single semi-floating bearing sleeve, and a dynamic oil clearance II exists between the full-floating bearing sleeve and the turbine rotating shaft. The floating bearing structure has the advantages of reasonable structure, high reliability, high efficiency and the like.

Owner:ZHEJIANG RONGFA MOTOR ENGINE

Method for producing skiving knife and equipment thereof

InactiveCN101219492AEasy machining accuracySmooth and sharp surfaceElectrochemical machining apparatusCooking vessel constructionsSmooth surfaceVoltage

The invention discloses a method to produce a scraping cutter by electrolytic method and a preparation thereof. The invention solves the disadvantages that the existing production method is toxic, pollutes the environment and the accuracy is not easy to control. A metal plate with surface provided with an anti electrolysis protective layer is electrolyzed by electrolytic method and the electrolyte strength can be controlled by adjusting electrolytic voltage or (and) electrolyte concentration or electrolyte velocity during the whole process, thereby ensuring the working precision is easier to control to obtain sharp cutter edge with smooth surface. Besides, raw materials in the invention applied have no harm to human body and do not pollute the environment.

Owner:林其添

A machining tool for high-precision elongated holes and its machining method

ActiveCN104625119BEasy machining accuracyImprove processing efficiencyTurning toolsReaming toolsSurface roughnessEngineering

The invention discloses a machining tool for high-precision elongated holes and a machining method thereof, which is characterized in that: the machining tool is integrally composed of a cylindrical boring part, a reaming part and a clamping part; It is fixedly connected with the rear end of the reaming part; a reamer groove is provided on the outer peripheral surface of the reaming part, and a reamer is arranged in the reamer groove; the front end of the reaming part is fixedly connected with the rear end of the boring part, and the The front end of the boring part is provided with a boring tool; during processing, firstly, the workpiece is rough-machined to obtain a slender hole, and the cutting allowance of the rough machining is controlled to be 1-2mm, and then the machining tool of the present invention is used to perform half-precision machining on the slender hole. Boring, high-precision reaming and surface strengthening extrusion can complete the processing of high-precision elongated holes. The machining tool of the invention has the advantages of simple structure, low cost, simple machining process, high machining efficiency, machining precision up to IT6 level, and the surface roughness of the machined holes can reach Ra0.4-1.6.

Owner:HEFEI ORIENT METALLURGICAL EQUIP

Simulation and test system for excavation of narrow foundation pit in high gravity field

PendingCN110939163AEasy to excavateStable supportFoundation testingExcavationsSupporting systemModel system

The invention relates to a simulation and test system for excavation of a narrow foundation pit in a high gravity field. The simulation and test system is composed of a foundation pit simulation system, a foundation pit supporting system and a measuring system, the foundation pit simulation system comprises a model box, a separating plate and an adjusting rod, the separating plate is vertically located in the model box, one end of the adjusting rod is connected to the separating plate, the other end of the adjusting rod abuts against the inner wall of the model box, the adjusting rod is used for adjusting the position of the separating plate, a space between the separating plate and the model box is used for containing test soil, and the test soil is formed by consolidating mud in the highgravity field; and the foundation pit supporting system includes two retaining walls arranged in parallel with excavated trenches and a supporting rod connected between the two retaining walls, the supporting rod is used for adjusting the distance between the two retaining walls, and the measurement system is used for measuring the strain of the retaining walls and conducting formation settlementmeasurement and changes in the displacement field. The simulation and test system can comprehensively measure various aspects of affects of foundation pit excavation in the high gravity field, can realize full excavation of a foundation pit and can achieve simulation of support adding.

Owner:上海市岩土地质研究院有限公司 +1

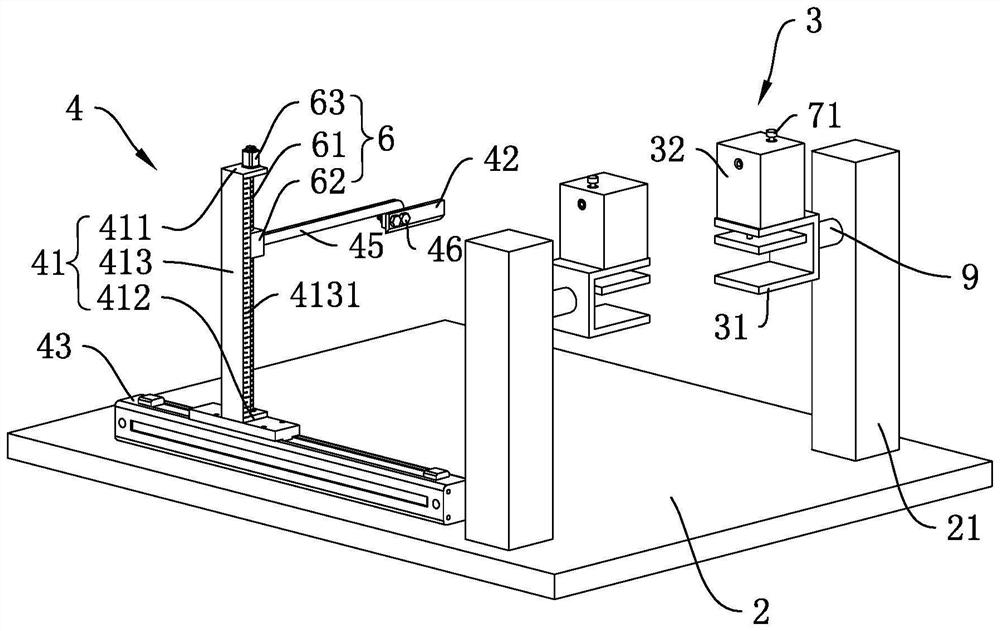

Special-shaped workpiece machining equipment and machining process thereof

InactiveCN114570829AEasy machining accuracyImprove machining accuracyProcess efficiency improvementWorkmanshipMachining process

The invention relates to the technical field of special-shaped workpiece machining, in particular to special-shaped workpiece machining equipment and a machining process thereof.The special-shaped workpiece machining equipment comprises a workbench and a scraping mechanism, the workbench is provided with two fixing columns, and the two fixing columns are symmetrically arranged and each provided with a clamping mechanism used for fixing a material plate; the scraping mechanism comprises an installation frame, a scraper arranged on the installation frame and a rodless air cylinder arranged on the workbench, the installation frame is fixed to a sliding table of the rodless air cylinder, and the rodless air cylinder can drive the scraper to move in the length direction of a cylinder body; and an adjusting mechanism for adjusting the height of the scraper is arranged on the mounting frame. The problem that the quality of workpieces is low can be solved.

Owner:苏州福丰联合电子有限公司

Rod integrator holder and projection type video display

InactiveUS20080079912A1Reduce necessityEasy accuracy requirementProjectorsColor television detailsIntegratorOptical axis

A guide convex portion is formed on a base plate in parallel to an illumination optical axis. Further, a fixed-side supporting member is provided in the base plate. A first opening is formed in an upright portion of the fixed-side supporting member. A slide supporting member can be provided on the base plate. A second opening is formed in the upright portion of the slide supporting member. By inserting a tapered rod into the second opening at its light incidence side and by moving the slide supporting member along the aforementioned guide convex portion, the slide supporting member is stopped at a predetermined position and, at this position, the slide supporting member is fixed.

Owner:SANYO ELECTRIC CO LTD

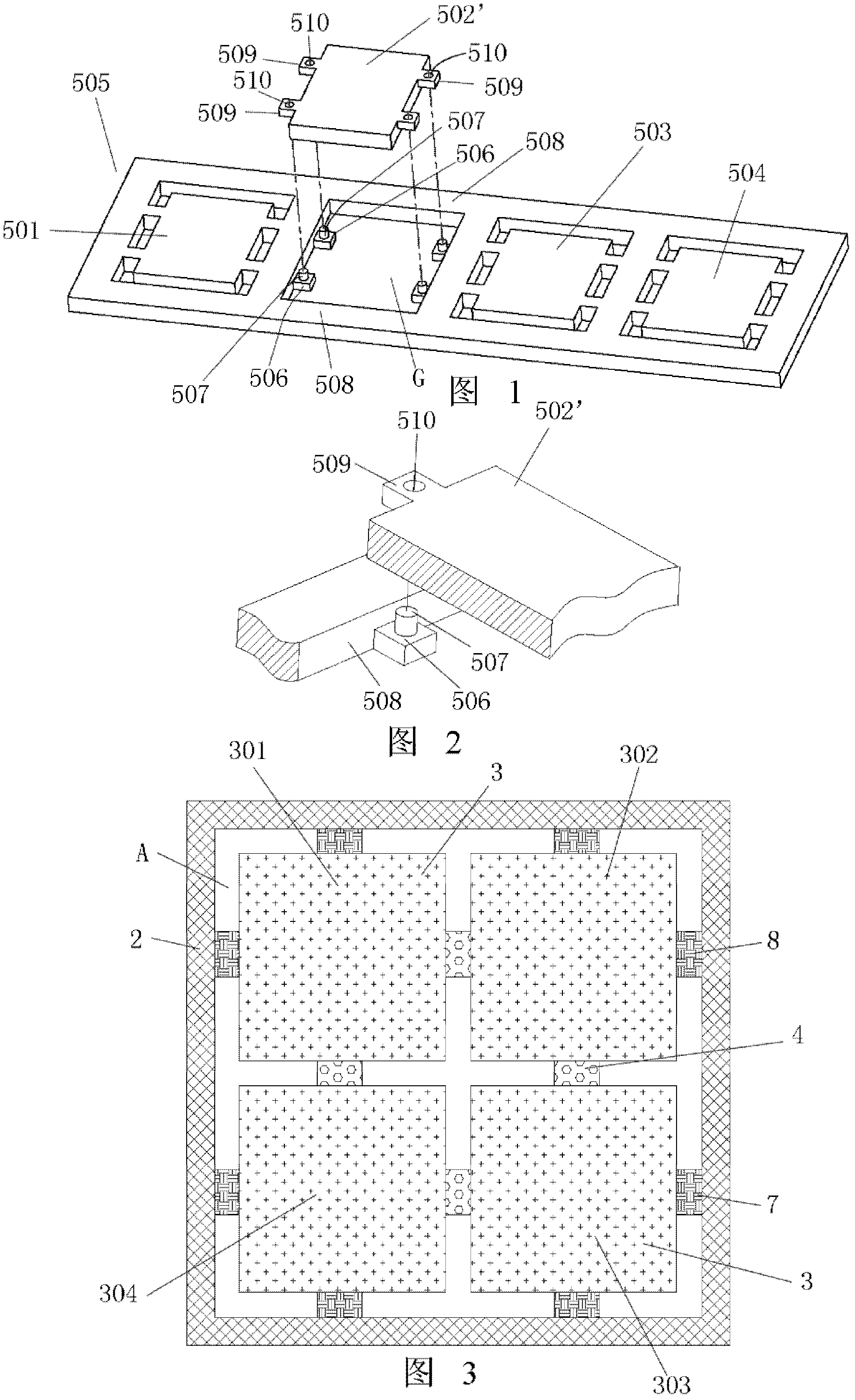

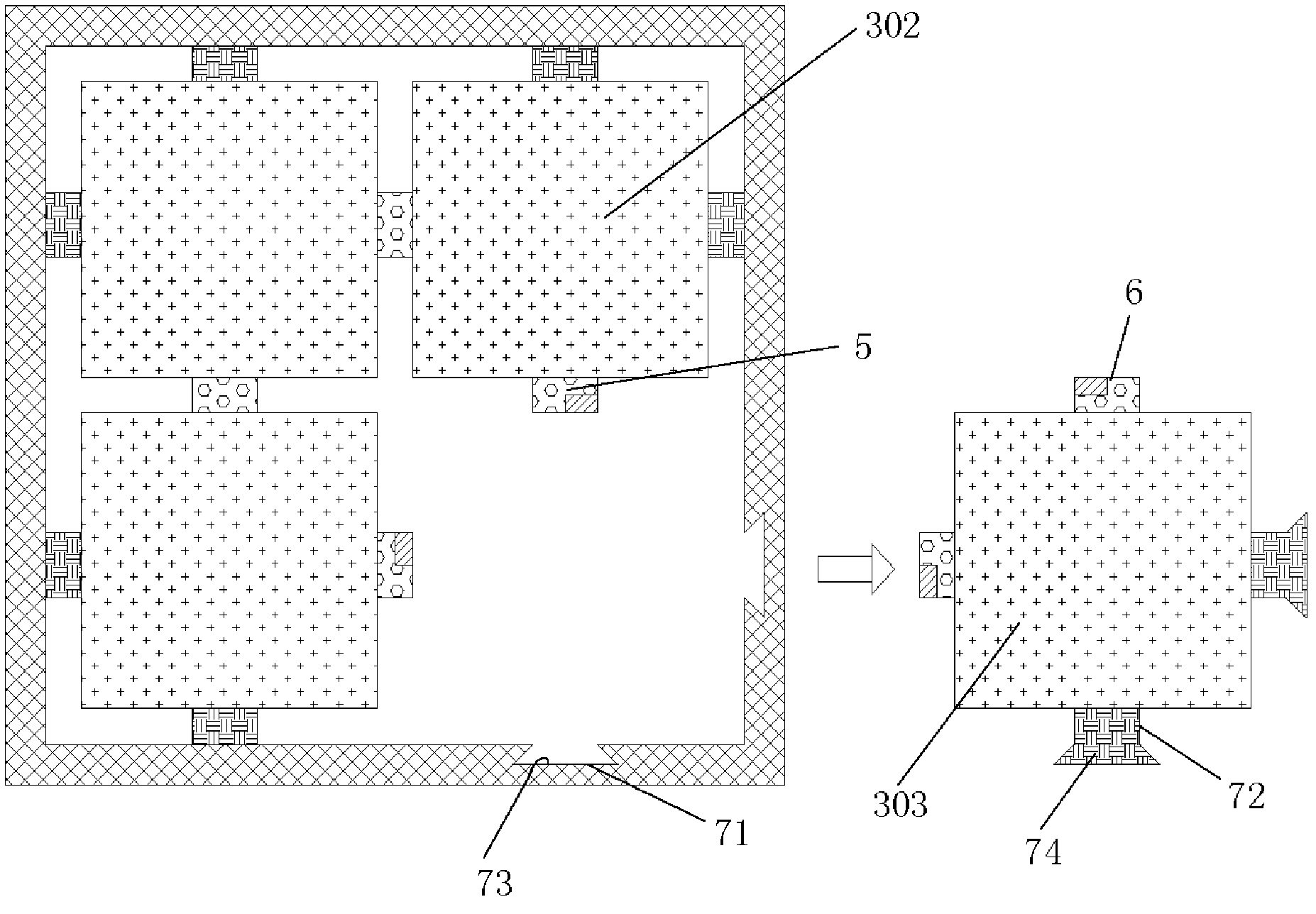

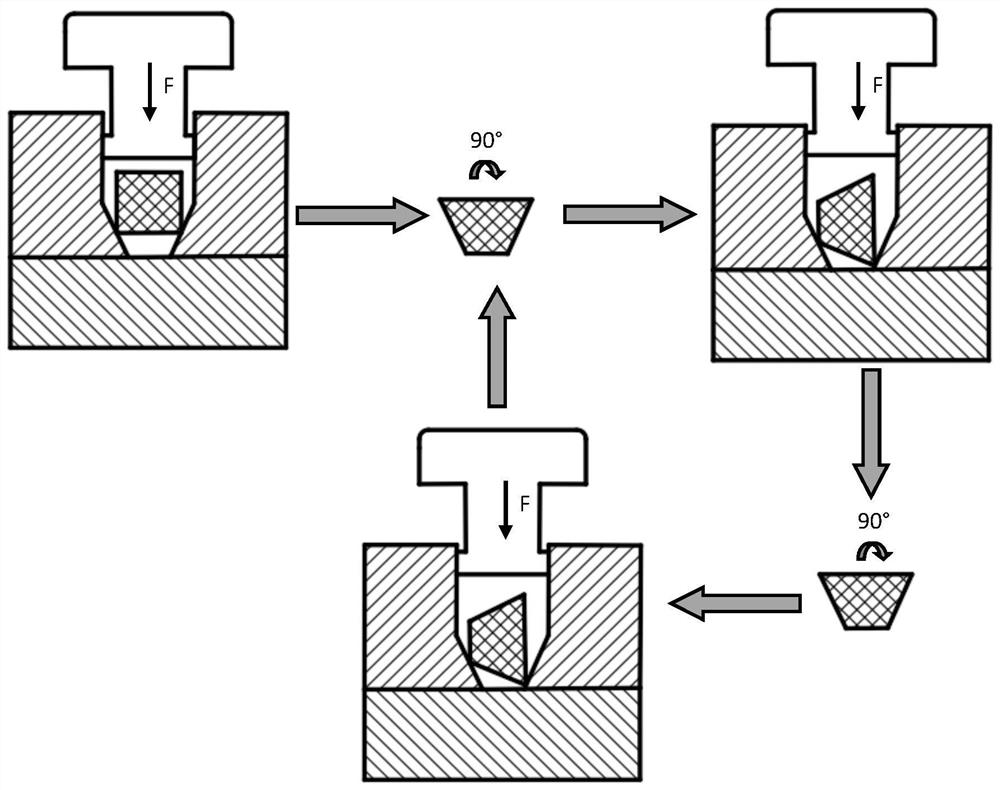

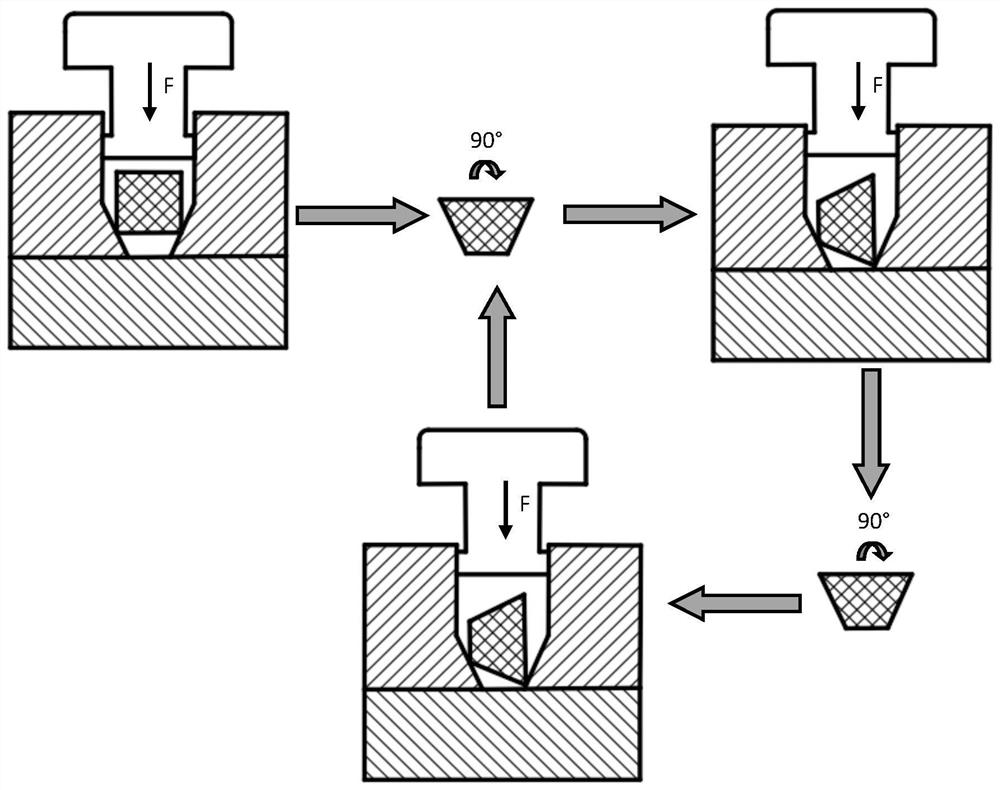

A kind of magnesium alloy profile multi-directional repeated extrusion deformation processing device and processing method

ActiveCN112090976BImprove mechanical propertiesGrain refinementExtrusion diesMetallic materialsEngineering

Owner:HUNAN UNIV OF SCI & TECH

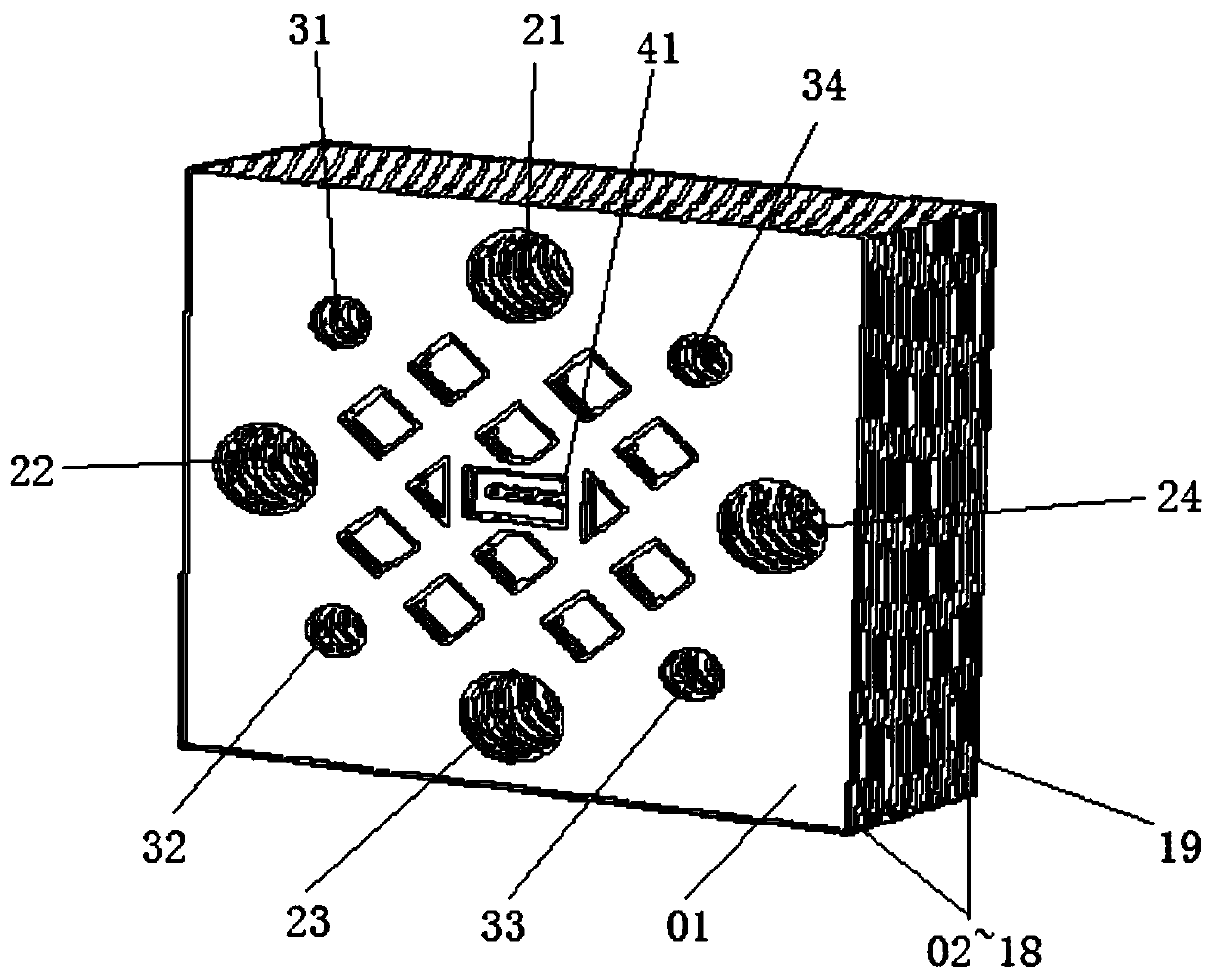

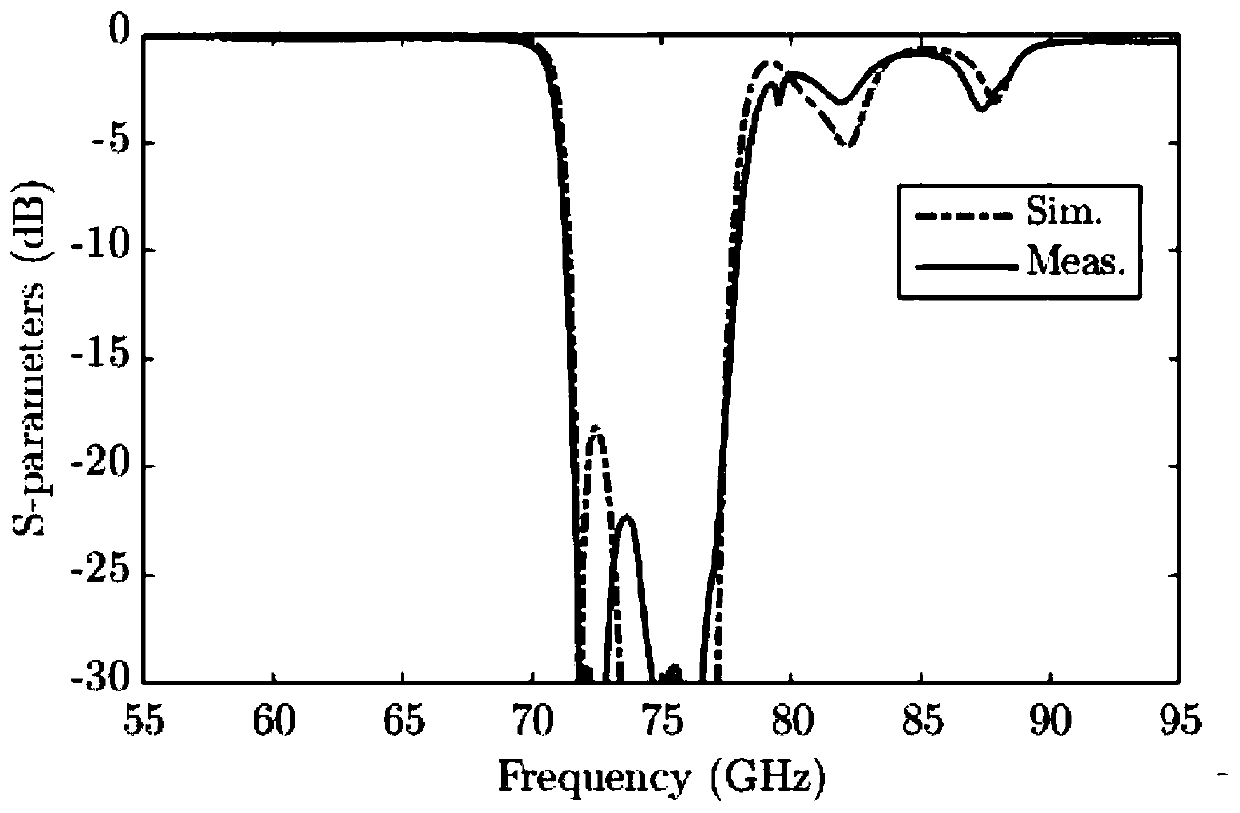

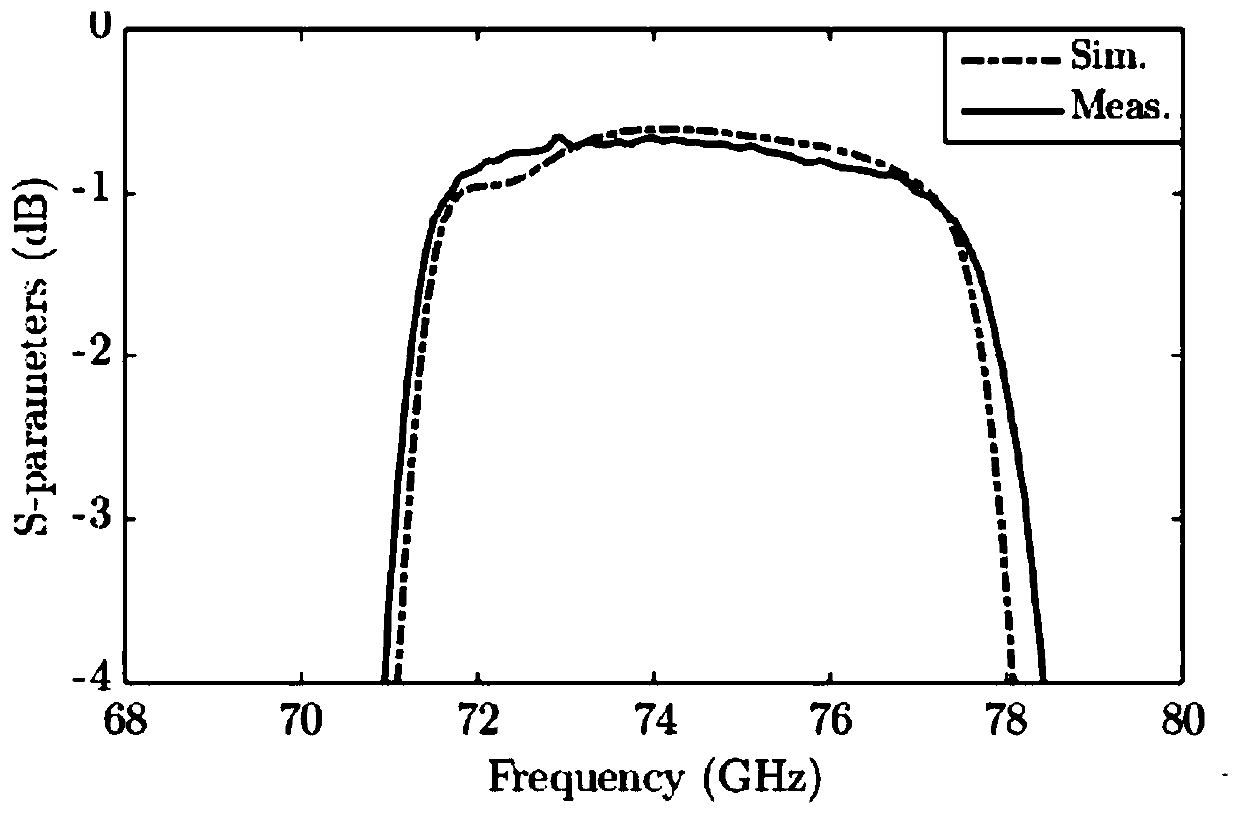

E-band low-loss EBG multilayer integrated band-pass filter

The invention relates to the technical field of radio frequency, and discloses an E-band low-loss EBG multilayer integrated band-pass filter. The filter comprises a three-dimensional structure formedby laminating a plurality of layers of electromagnetic band gap structure unit patches of two-dimensional structures, wherein a gap is formed between every two adjacent electromagnetic band gap structure unit patches, ad a coupling hole is formed in the center of each electromagnetic band gap structure unit patch, and the size of each coupling hole is gradually changed in the laminating direction.According to the technical scheme provided by the invention, the three-dimensional cavity structure is realized by adopting a gradual change type electromagnetic band gap structure unit patch laminated structure; compared with a traditional cavity filter, the filter is easier to process, saves the cost, and solves the problem of low processing precision; according to the technical scheme, while the band-pass filter is achieved, due to the fact that the vertical structure is adopted, the plane size of the filter is greatly reduced especially when high-order design is carried out, thereby facilitating miniaturization design; according to the technical scheme, the propagation of electromagnetic waves in a certain direction or propagation in all directions can be prevented within a certain frequency band.

Owner:AEROSPACE SCI & IND MICROELECTRONICS SYST INST CO LTD +1

Novel robot equipment

InactiveCN108214503AAchieve vertical movementRealize processingManipulatorEngineeringVertical control

The invention discloses novel robot equipment which comprises a clamping fixing part, an end body, a vertical control device, a transverse control device and a clamping fixing device. A long strip isarranged on the left side of the clamping fixing part, and the upper end face and the lower end face of the right side of the clamping fixing part are each provided with a guide strip in the front-back direction. The right side of the end body is provided with a guide concave hole in sliding fit with the guide strip in the front-back direction. The vertical control device is installed on the leftside of the end body, penetrates rightwards into a first through groove and then penetrates into a step set in the middle end of the right side face of the clamping fixing part. The clamping fixing device is installed on the vertical control device located on the left side of the end body. The transverse control device is installed on the clamping fixing device. Size control is convenient, operation is convenient and fast, machining precision can be ensured, and the machining efficiency can be improved.

Owner:GUANGZHOU LEANLITE OPTIC ELECTRONICS TECH CO LTD

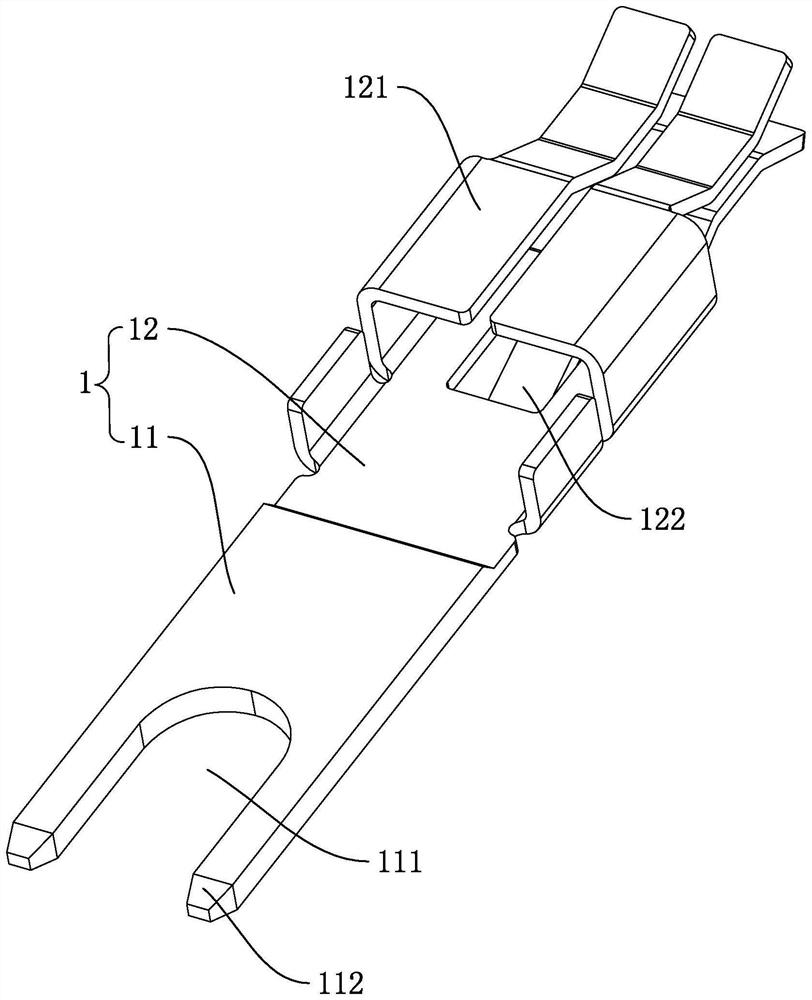

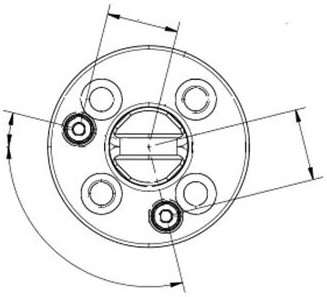

Tooth profile bending assembly for anchoring part machining

The invention discloses a tooth profile bending assembly for anchoring part machining. The tooth profile bending assembly for anchoring part machining comprises a bottom disc and a bending head. A through hole, a first mounting hole, a second mounting hole and multiple fixing holes are formed in the bottom disc. The bending head comprises a head portion, a neck portion and a rotary shaft which aresequentially connected. A first tooth block and a second tooth block are arranged on the head portion. A bending gap is formed between the first tooth block and the second tooth block. The head portion can pass through the through hole, and the diameter of the neck portion is larger than the internal diameter of the through hole. A first bending roller is mounted on the first mounting hole, and asecond bending roller is mounted on the second mounting hole. The rotary shaft can drive the head portion to rotate in the through hole. The tooth profile bending assembly for anchoring part machining can efficiently machine anchoring parts.

Owner:ANHUI WUHU CONCH CONSTR & INSTALLATION ENG

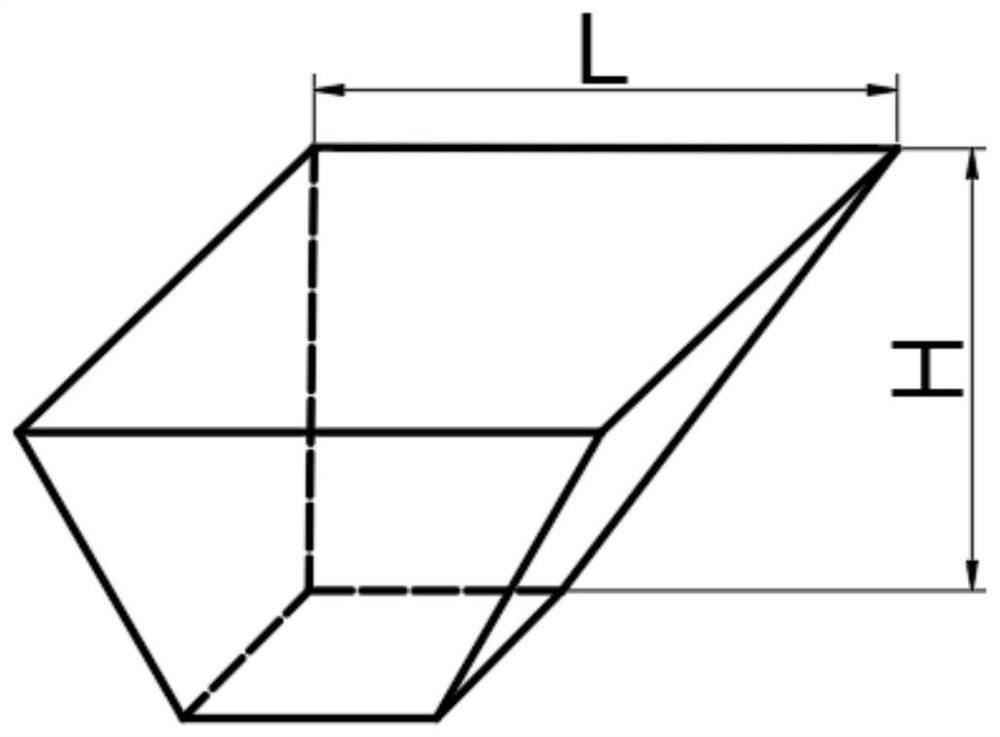

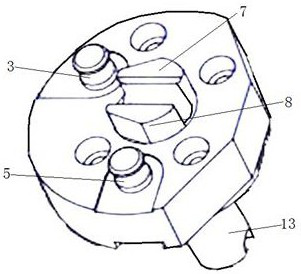

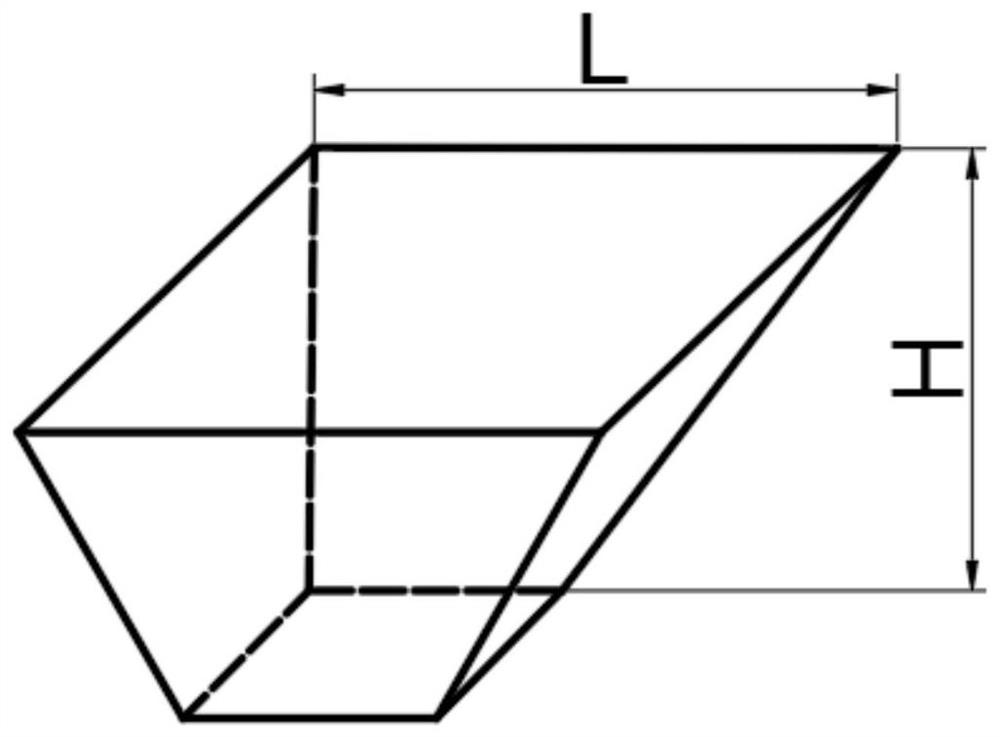

Multi-directional repeated extrusion deformation processing device and procesisng method for magnesium alloy profile

The invention relates to the technical field of metal material processing equipment, in particular to a multi-directional repeated extrusion deformation processing device and a processing method for amagnesium alloy profile. The processing device comprises a male die, an upper female die and a lower female die; the upper female die is provided with a die cavity; the die cavity is composed of a male die channel and an extrusion channel; the male die channel is in a cuboid shape; the extrusion channel is in an inverted regular quadrangular frustum pyramid shape; the upper female die and the lower female die are connected, positioned and combined into the female die through screws and pins; and the male die is arranged in the male die channel and is matched with the male die channel. The processing device provided by the invention is simple in structure, convenient to operate, beneficial to extrusion sample demolding, capable of preparing a large number of high-performance magnesium alloy products of various sizes, capable of improving the production efficiency and the processing precision, easy to disassemble, convenient to maintain, small in abrasion to the male die under the condition of long-time extrusion production, and the magnesium alloy processed by the device has good strength, plasticity and corrosion resistance.

Owner:HUNAN UNIV OF SCI & TECH

Robot equipment

InactiveCN107282955AAchieve vertical movementRealize processingBoring barsEngineeringProcessing accuracy

The invention discloses a robot device, which comprises a clamping piece, an end body, a vertical control device, a horizontal control device and a clamping device. A long strip is arranged on the left side of the clamping piece, and a front-back direction is respectively set on the upper and lower end surfaces of the right side. The right side of the end body is provided with a guide concave hole in the front and rear directions that slides and fits with the guide bar, and the vertical control device is installed on the left side of the end body and penetrates to the right The first through groove penetrates into the step group at the middle end of the right side of the clamp, the clamping device is installed on the vertical control device on the left side of the end body, and the horizontal control device Installed on the clamping device; the present invention is convenient in size control and convenient in operation, which can not only ensure the machining accuracy, but also improve the machining efficiency.

Owner:宣城尤达美智能科技有限公司

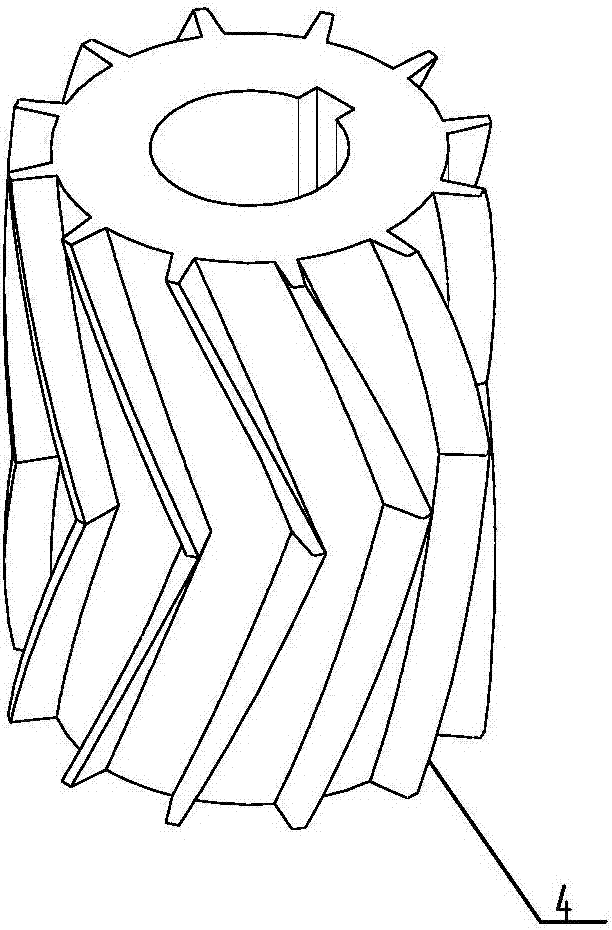

Novel pulverized coal metering and conveying equipment

The invention discloses novel pulverized coal metering and conveying equipment which comprises a feeding bin and a drive motor. A drive shaft is connected to the drive motor. The feeding bin is provided with a feed opening and a discharge opening which directly face each other. The drive shaft is inserted into the feeding bin and provided with a feeding gear. The appearance of the feeding gear is just matched with the shape of an inner cavity of the feeding bin. Herringbone teeth are arranged on the outer wall of the feeding gear. The problems that the occupied area is large, and maintenance is difficult are solved; and the novel structure is adopted, and a mechanism achieving conveying through the herringbone tooth gear is adopted. Under the condition that the conveying quantity is not changed, the novel gear conveying mechanism is adopted, and equipment replacement can be conveniently carried out in limited space. The herringbone gear structure is adopted, the shaft becomes shortened, the machining precision and mounting precision are easier to guarantee, and the platform cost is reduced.

Owner:石家庄圣宏达热能工程技术股份有限公司

Machining device for inner groove of lathe

InactiveCN107891161ARealize processingControl Radial DimensionsAuxillary equipmentTool holdersEngineering

The invention discloses a machining device for an inner groove of a lathe. The machining device for the inner groove of the lathe comprises a clamping piece, a body, a groove depth control device, anaxial positioning size control device and a clamping device; a long rectangle convex strip is arranged on the left side of the clamping piece; the upper surface and the lower surface of the right sideof the clamping piece are each provided with a rectangular guide rail convex strip in the front-back direction; a guide rail groove in the front-back direction and in sliding fit with the rectangularguide rail convex strips is formed in the right side of the body; the groove depth control device is installed on the left side of the body and rightwards penetrates a first through hole to finally stretch into a combined groove in the middle portion of the right side face of the clamping piece; the clamping device is installed on the portion, located on the left side of the body, of the groove depth control device; and the axial positioning size control device is installed on the clamping device. The machining device for the inner groove of the lathe facilitates size control, is convenient and fast to operate, can guarantee the machining precision and can also improve the machining efficiency.

Owner:莫金连

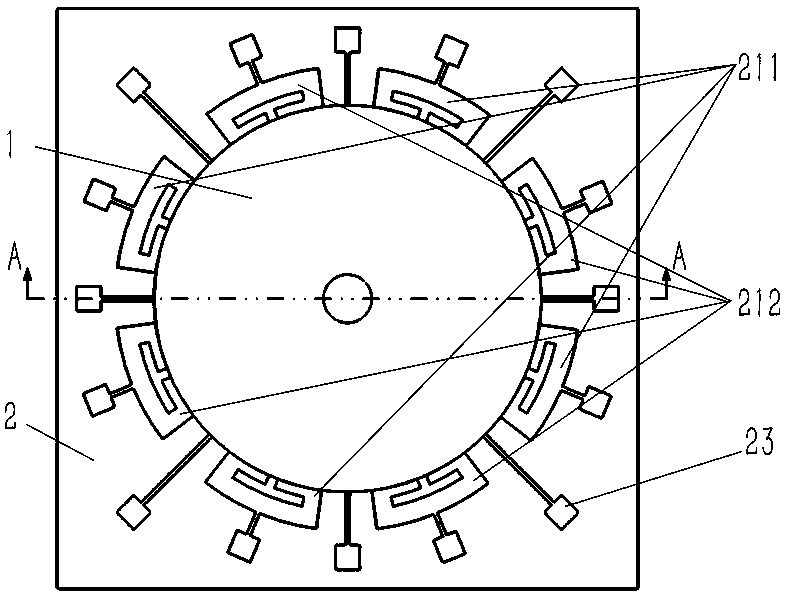

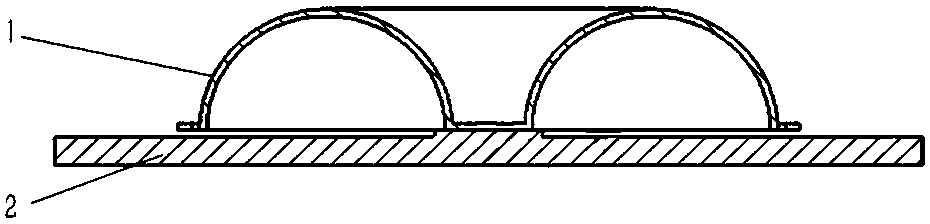

Microshell vibrating gyroscope and preparation method thereof

ActiveCN105698780BEasy to processEasy machining accuracySpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesOut of planeHarmonic oscillator

The invention discloses a micro shell vibration gyroscope and a preparation method thereof. The micro shell vibration gyroscope comprises a micro shell gyroscope harmonic oscillator and a glass substrate. The micro shell gyroscope harmonic oscillator is arranged on the glass substrate; the micro shell gyroscope harmonic oscillator comprises a rotating shell and a plurality of sensitive mass components; the sensitive mass components are uniformly distributed on the periphery of the bottom of the rotating shell; metal films are arranged on surfaces of the rotating shell and the plurality of sensitive mass components, which are opposite to the glass substrate; the glass substrate comprises a plurality of fixed capacitor plates; the plurality of fixed capacitor plates correspond to the plurality of sensitive mass components. The preparation method comprises: preparing the micro shell gyroscope harmonic oscillator by a high-accuracy contact pattern; carrying out micro assembling. The micro shell vibration gyroscope carries out driving and detection based on out-of-plane, and has the advantages of convenience in machining, high machining accuracy, high driving and detecting efficiency, convenience in mode and frequency trimming, good robustness, low cost and the like. The preparation method can greatly improve surface form machining accuracy of a three-dimensional curved surface and structural symmetry of the micro shell gyroscope harmonic oscillator.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com