Method for producing skiving knife and equipment thereof

A technology for scraping knives and equipment, applied in the field of manufacturing scraping knives and equipment, can solve the problems of harmful environment for personnel, violent reactions, pollution, etc., and achieve the effects of easy processing accuracy, smooth and sharp surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

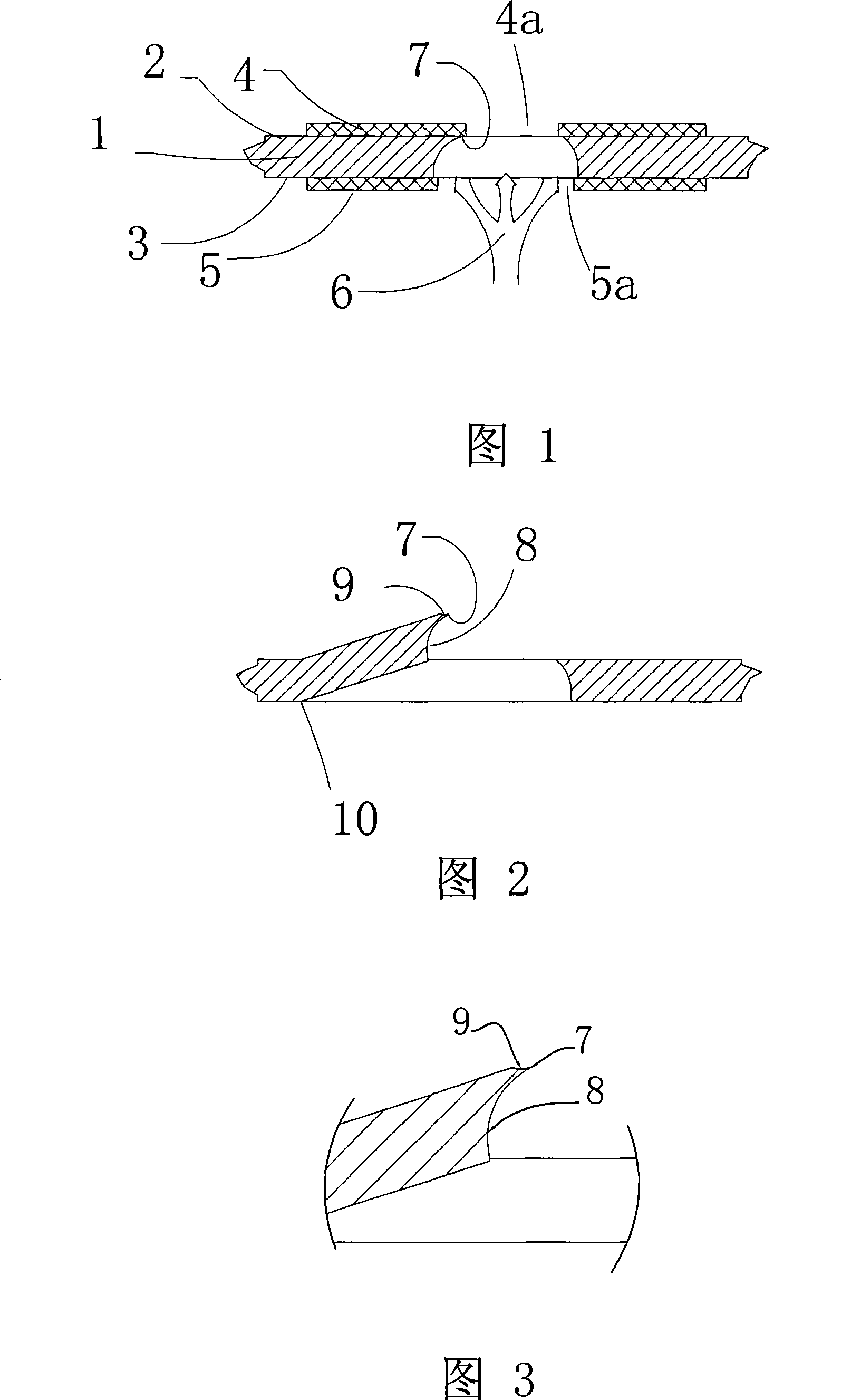

[0019] The method for manufacturing the scraper provided by the present embodiment, as shown in Fig. 1, Fig. 2 and Fig. 3, comprises the steps:

[0020] a. Cover the electrolytic protective layer on the thin metal plate, and use a printing machine to print the common ink used in traditional printing on the front surface 2 and the rear surface 3 of the metal plate 1 to form an electrolytic protective layer. During the printing process, the metal plate 1 Electrolysis window 4a and electrolysis window 5a (that is, the gap of the protection layer) are correspondingly opened on the front and rear surface protective layers 4 and 5 respectively. , compared with the electrolysis window 4a on the front surface of the scraper, it is widened on the side of the knife root (protruding from the root of the blade) 10;

[0021] b. Put the metal plate in the electrolytic tank, connect the positive pole of the DC power supply to the metal plate (the metal plate is used as the electrolysis anode...

Embodiment 2

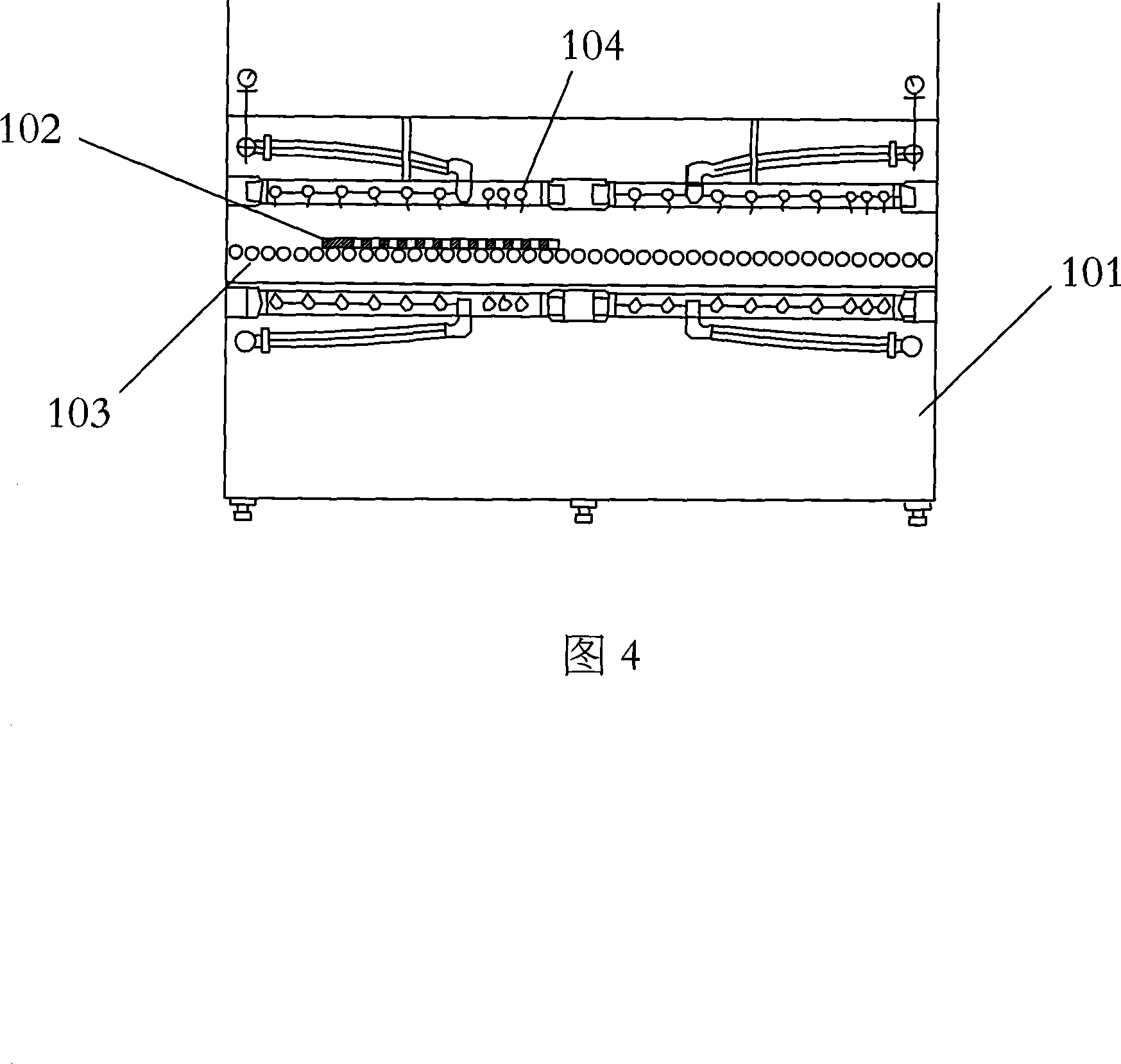

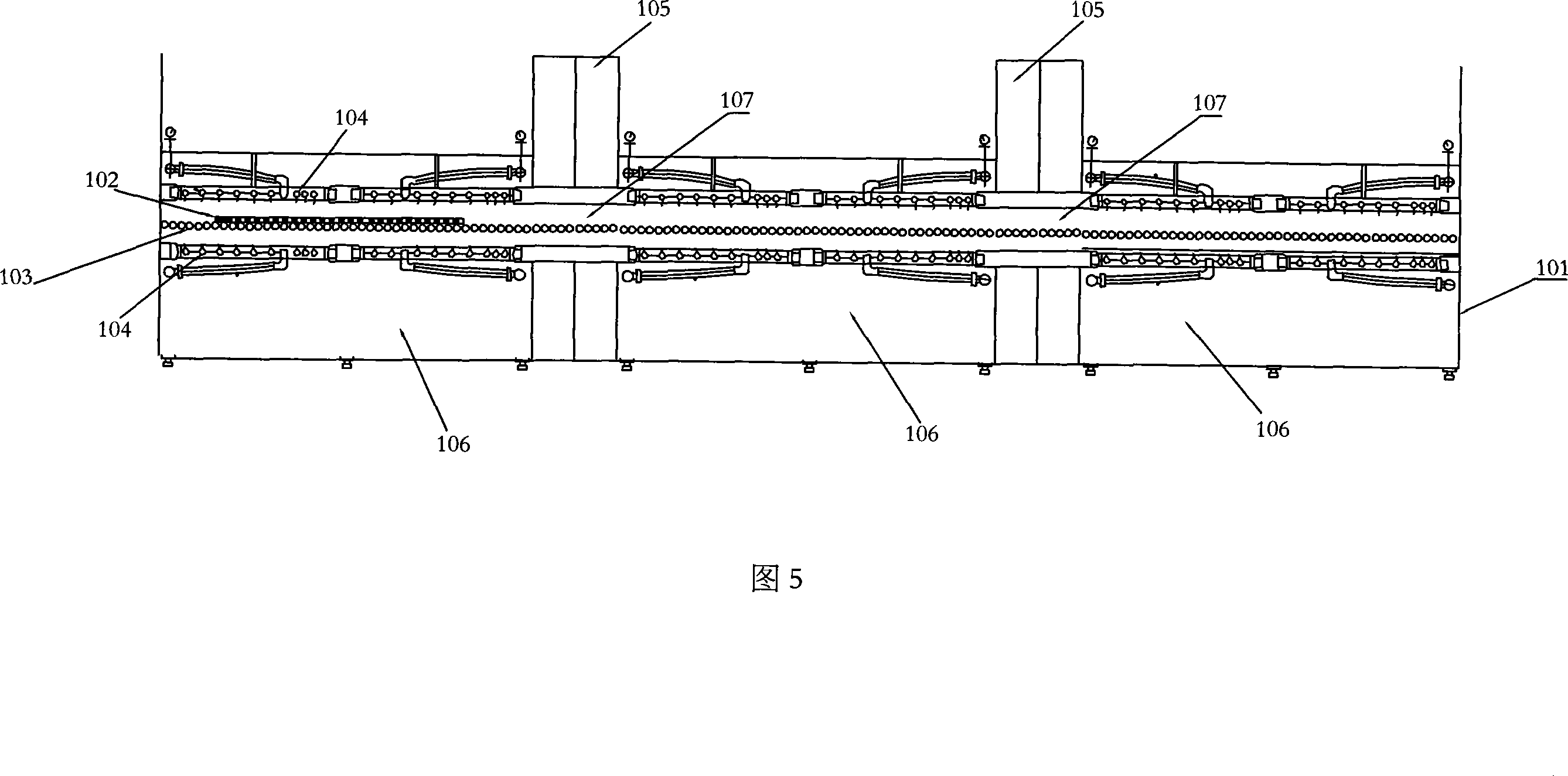

[0029] The equipment that manufacture scraper method adopts, as shown in Figure 5, there are two dividing plates 105 in its electrolyzing tank 101 and electrolyzing tank and electrolyte nozzle are divided into three compartments 106, and each dividing plate 105 is arranged to allow The passage 107 through which the workpiece and the roller group pass, in each compartment, the workpiece (the metal plate with the electrolysis window) 102 and the electrolyte can be electrically connected to a corresponding independent DC power supply for its electrolysis respectively, and the power supply voltage can be Adjustment; in each compartment, a group of independent electrolyte nozzles are provided on both sides of the roller, and each group of independent nozzles has its corresponding liquid supply pipeline, and there are switches and flow controls for the electrolyte on the respective pipelines. Valve, all the other are the same with the equipment described in embodiment 1.

[0030] Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com