Turn-over driving device of vehicle-mounted flat-panel display

A flat-panel display and driving device technology, which is applied in the direction of transmission, transmission parts, gear transmission, etc., can solve the problem of the large thickness of the vehicle-mounted flat-panel display overturning driving device, not adapting to the application trend of the vehicle-mounted flat-panel display, and the high processing cost of the box 25. problem, to achieve the effect of strong impact resistance, easy processing, and reduced processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

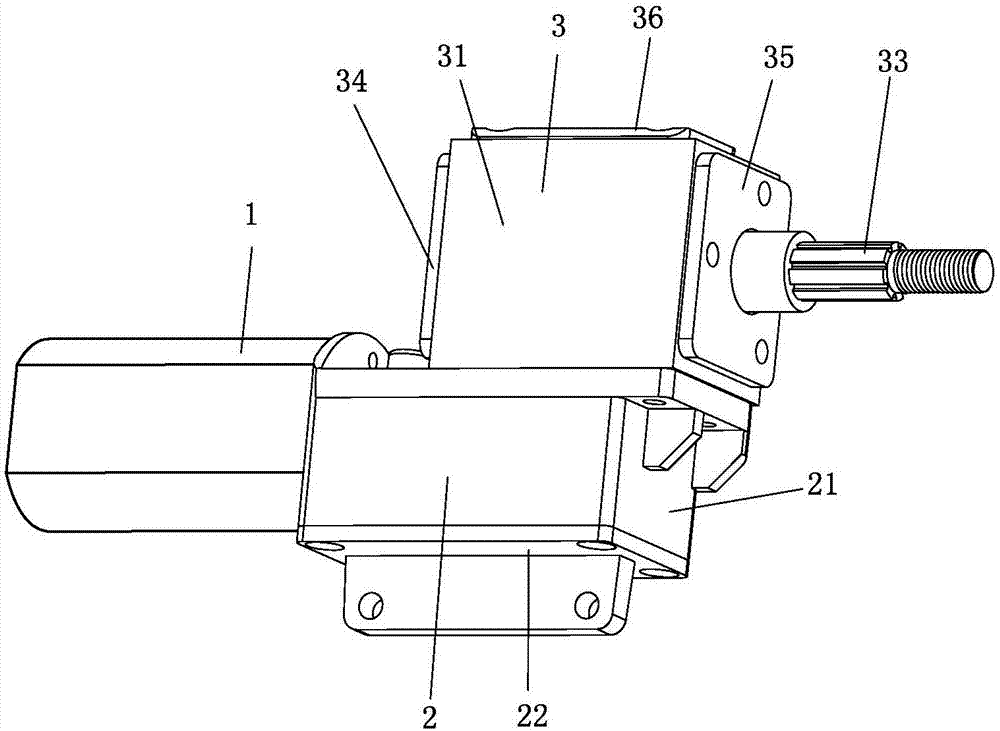

[0025] The three-dimensional structure of the vehicle-mounted flat panel display flip drive device of the present invention, such as figure 1 shown. It contains three main parts of motor 1, first reducer 2 and second reducer 3. In order to reduce the thickness of the entire display turning drive device, the motor 1 adopts a high-speed DC motor with a smaller diameter. In order to reduce the processing difficulty of the reducer case, the first reducer 2 and the second reducer 3 each have an independent case.

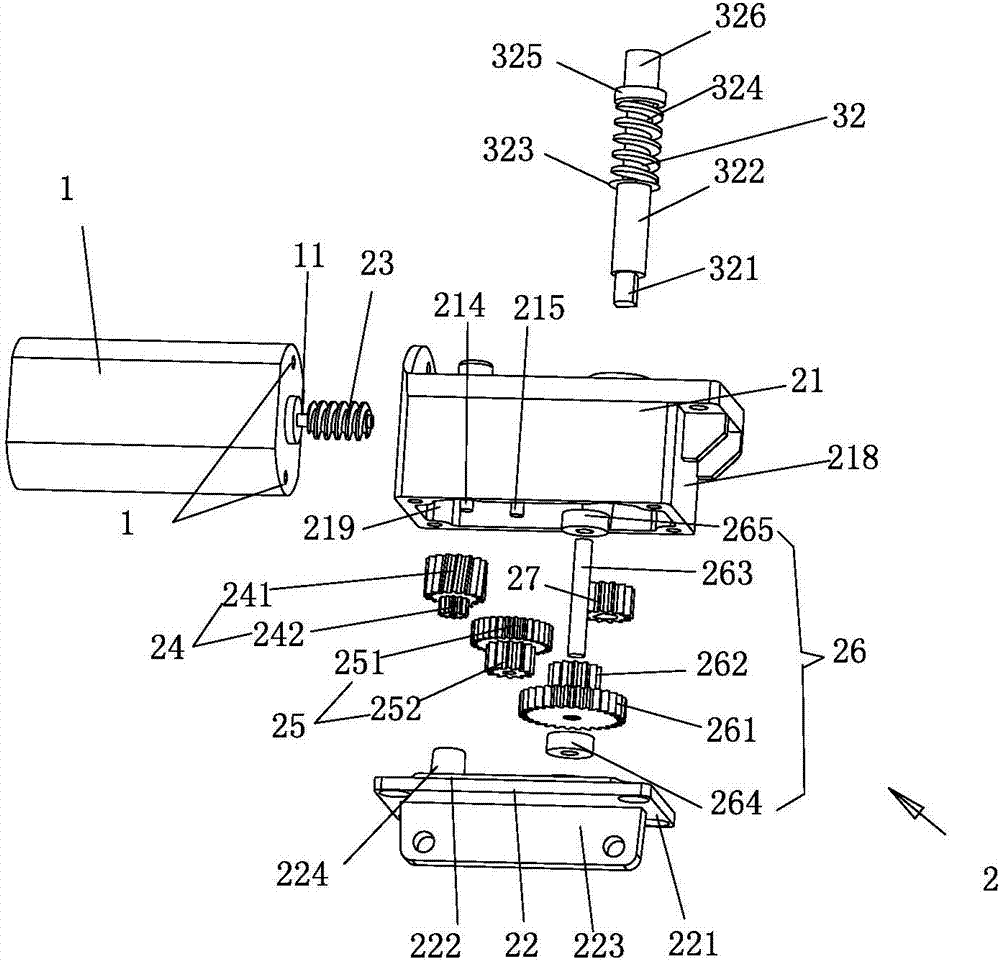

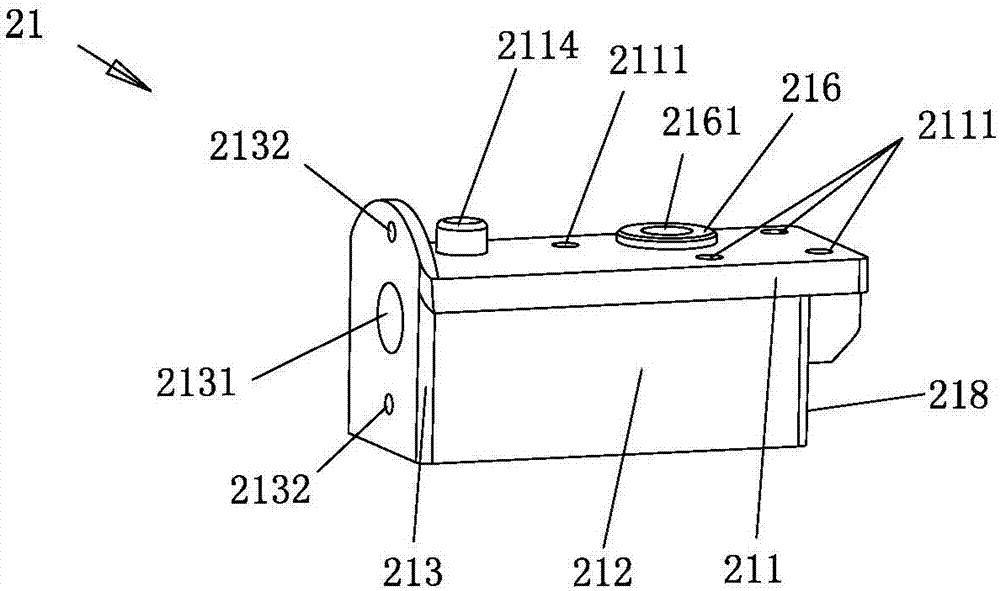

[0026] Please see figure 2 : the first speed reducer 2 comprises a first casing 21, a first case cover 22, a first worm 23, a first worm wheel 241, a first worm shaft 214, a first pinion 242, a first large gear 251, a second small The gear 252 , the first gear shaft 215 , the second large gear 261 , the third pinion 262 , the second gear shaft 263 , the first bearing 264 , the second bearing 265 and the output gear 27 . Wherein, the first small gear 242 , the first l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com