A machining tool for high-precision elongated holes and its machining method

A technology for processing cutting tools and processing methods, which is applied in the direction of lathe cutting tools, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult to meet high-precision hole processing, difficult to guarantee processing accuracy, complex processing technology, etc., to improve processing Efficiency and machining accuracy, hardness and tensile strength increase, and the effect of simplifying the machining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Provide the embodiment of the present invention below in conjunction with accompanying drawing:

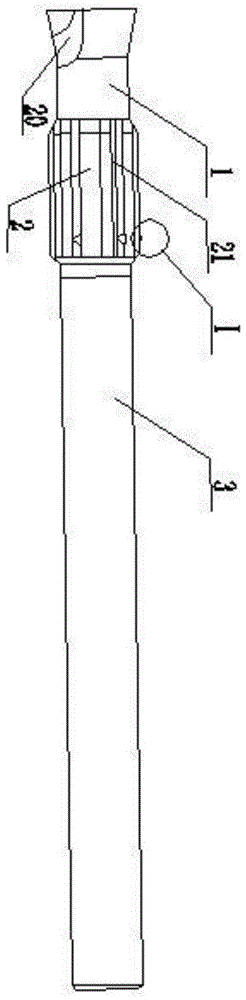

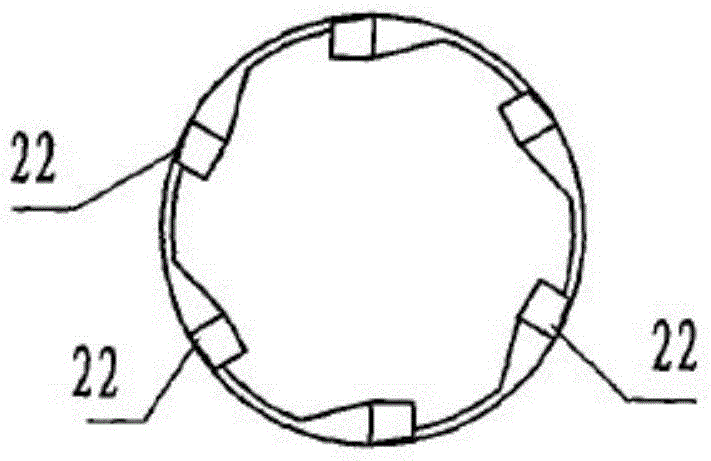

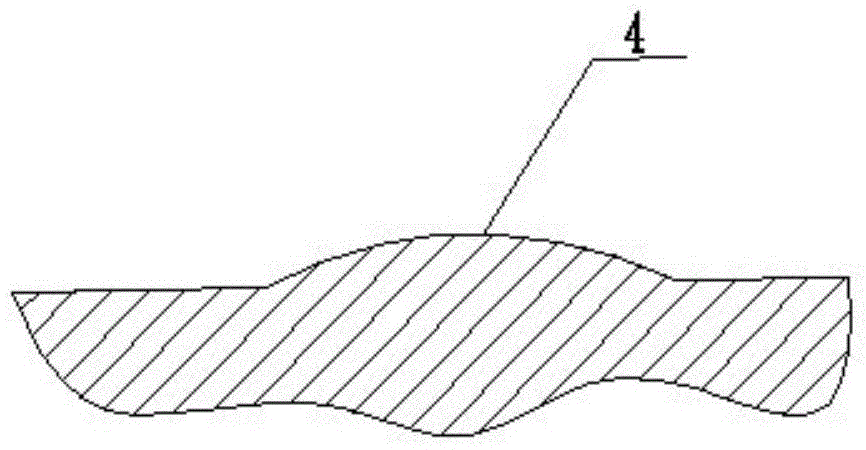

[0024] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the high-precision elongated hole machining tool of the present invention is composed of a cylindrical boring part 1, a cylindrical reaming part 2 and a cylindrical clamping part 3; the boring part, the reaming part and the clamping part 3 is cylindrical, easy to clamp, and can be easily clamped on the chuck of the machine tool; the front end of the clamping part 3 is fixedly connected to the rear end of the reaming part 2; a reamer is provided on the outer peripheral surface of the reaming part Groove 21, the direction of reamer groove 21 is parallel to the feeding direction of machining tool, and reamer 22 for carrying out high-precision reaming to slender hole is arranged in reamer groove 21;

[0025] The front end of the reaming unit 2 is fixedly connected to the rear end of the boring unit 1 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com