Deep hole processing tool structure

A tooling and deep hole technology, which is applied in the field of tooling structure for deep hole processing inside the workpiece, can solve the problems of difficult machining of the box, increased processing difficulty, and difficulty in machining the deep hole of the spindle box, and achieves simple assembly, improved processing efficiency, well-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

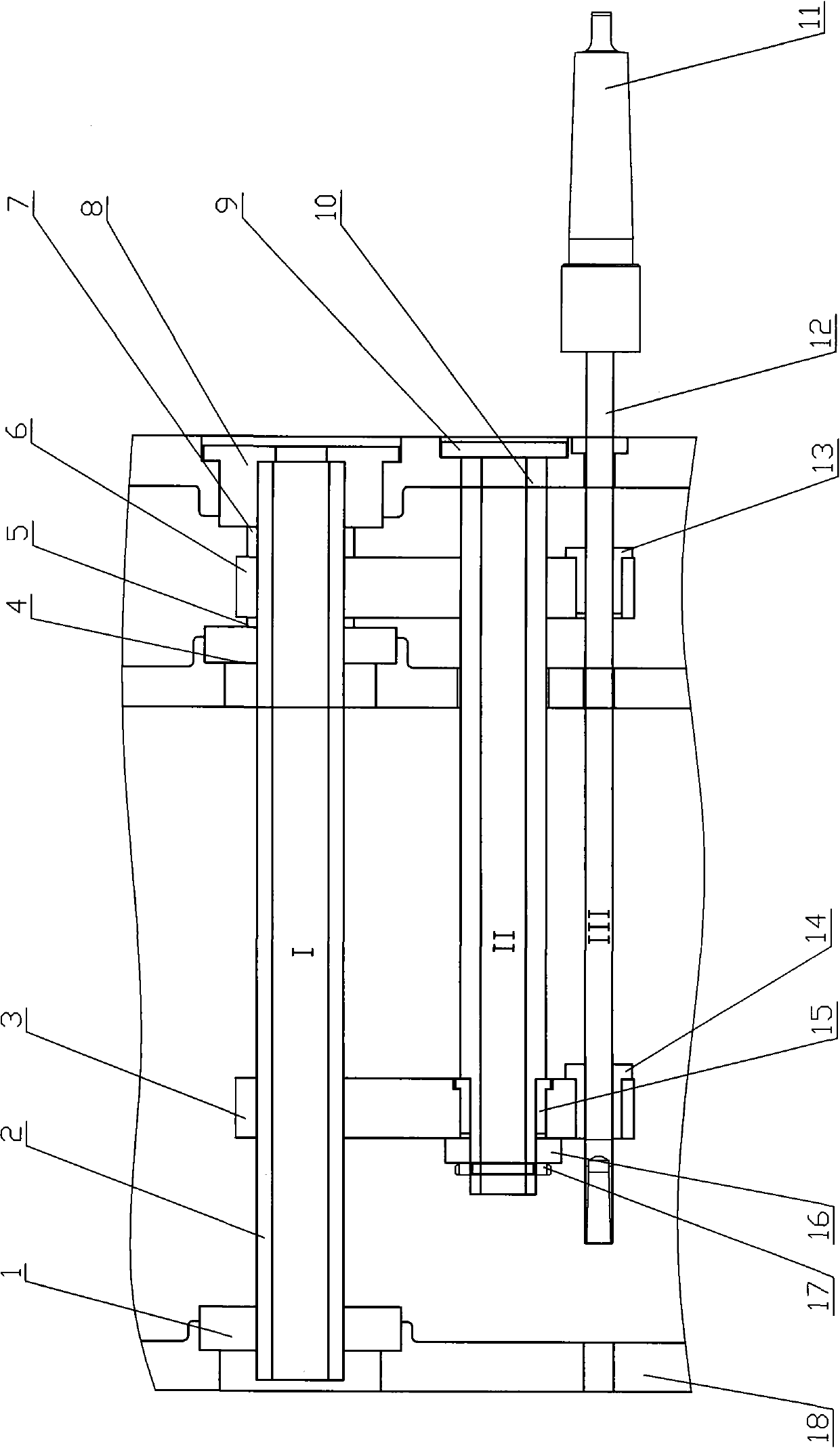

[0011] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

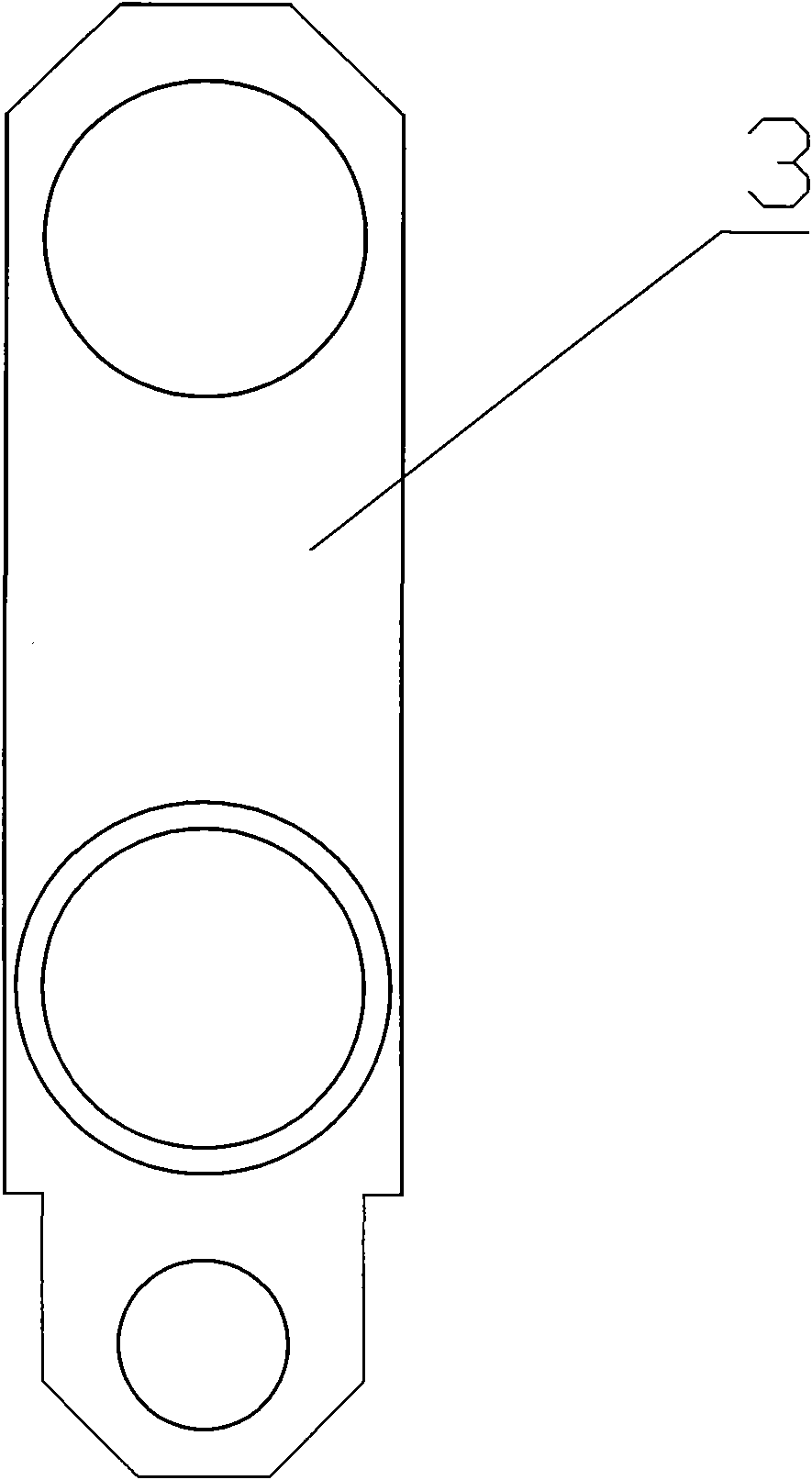

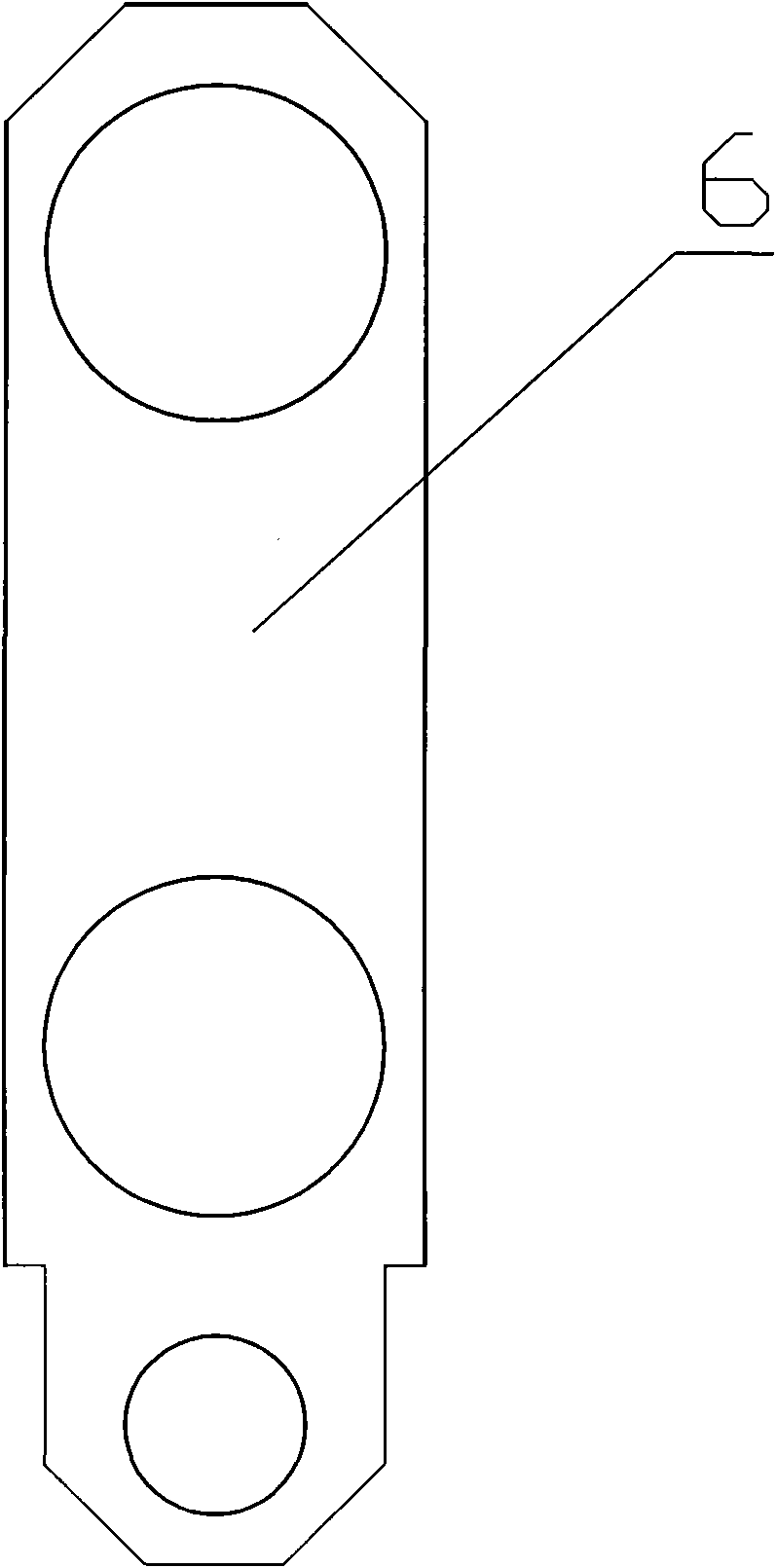

[0012] Such as Figure 1 ~ Figure 3 Shown: including the first positioning sleeve 1, the first fixed shaft 2, the first positioning plate 3, the second positioning sleeve 4, the first spacer 5, the second positioning plate 6, the second spacer 7, and the first flange Cover 8, second flange cover 9, second fixed shaft 10, tool handle 11, boring shaft 12, first set 13, second set 14, third set 15, pad 16, lock nut 17 and box 18 .

[0013] The present invention adopts the first positioning sleeve 1, the second positioning sleeve 4 and the first flange cover 8 to be fastened and connected to the machined surface at the position of the first fixed shaft 2 of the box body 18 by screws. The first fixed shaft 2 Cooperate with the inner hole of the first positioning sleeve 1, the second positioning sleeve 4 and the first flange cover 8, and connect with the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com