Crisscross section total-prefabricated-type anti-buckling supporting member

An anti-buckling bracing, cross-shaped technology, applied in building components, earthquake-proof, protective buildings/shelter, etc., can solve the problems of complicated production and installation, difficult to meet the accuracy of reserved gaps, etc., and achieve enhanced energy consumption. , The effect of easy control of machining accuracy and improved ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A cross-section fully assembled anti-buckling support member of the present invention will be described in detail below with reference to embodiments and drawings.

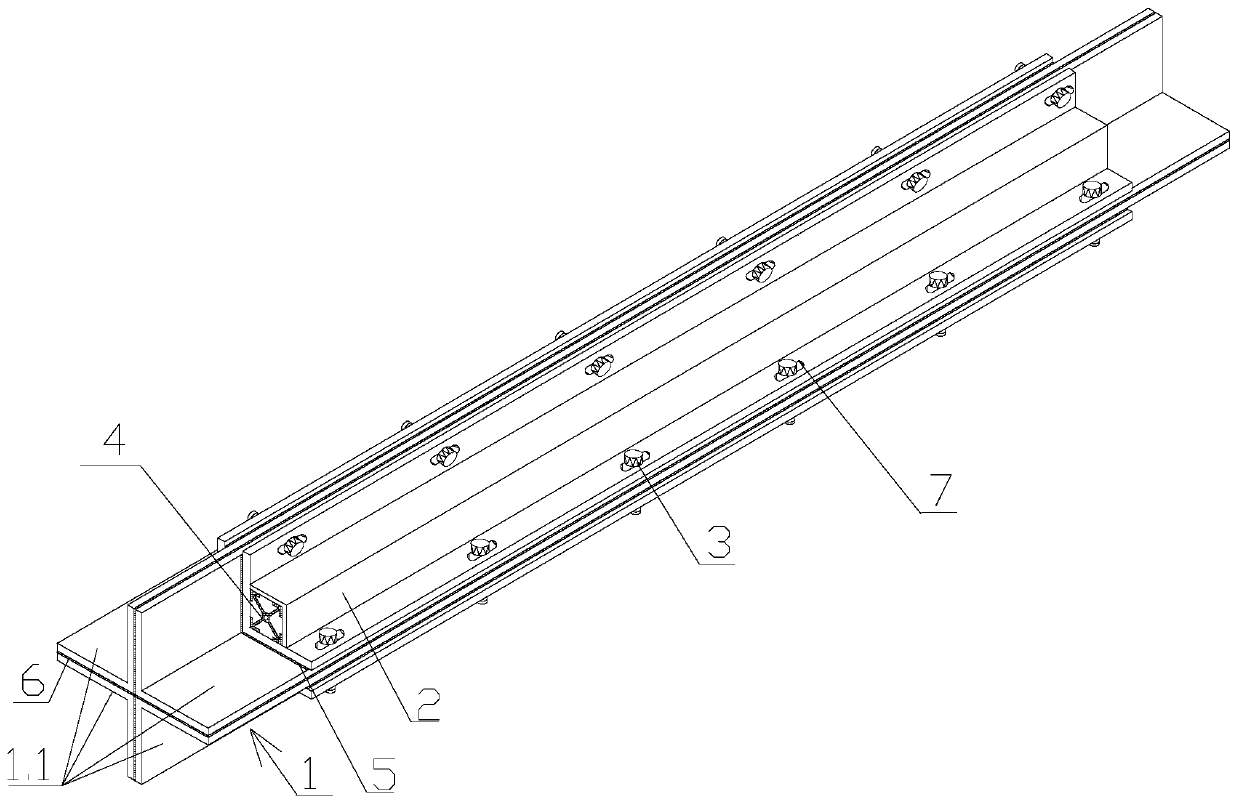

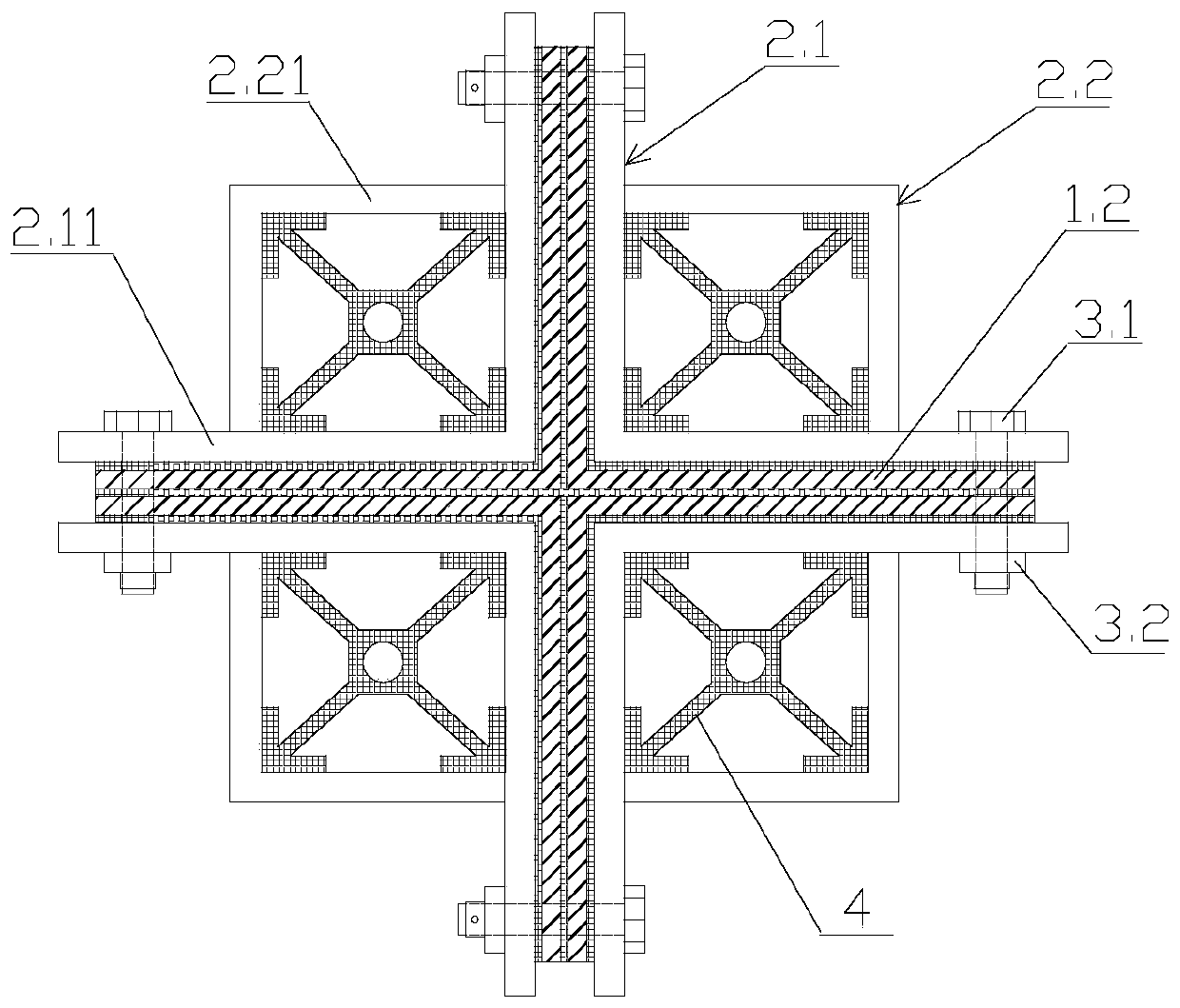

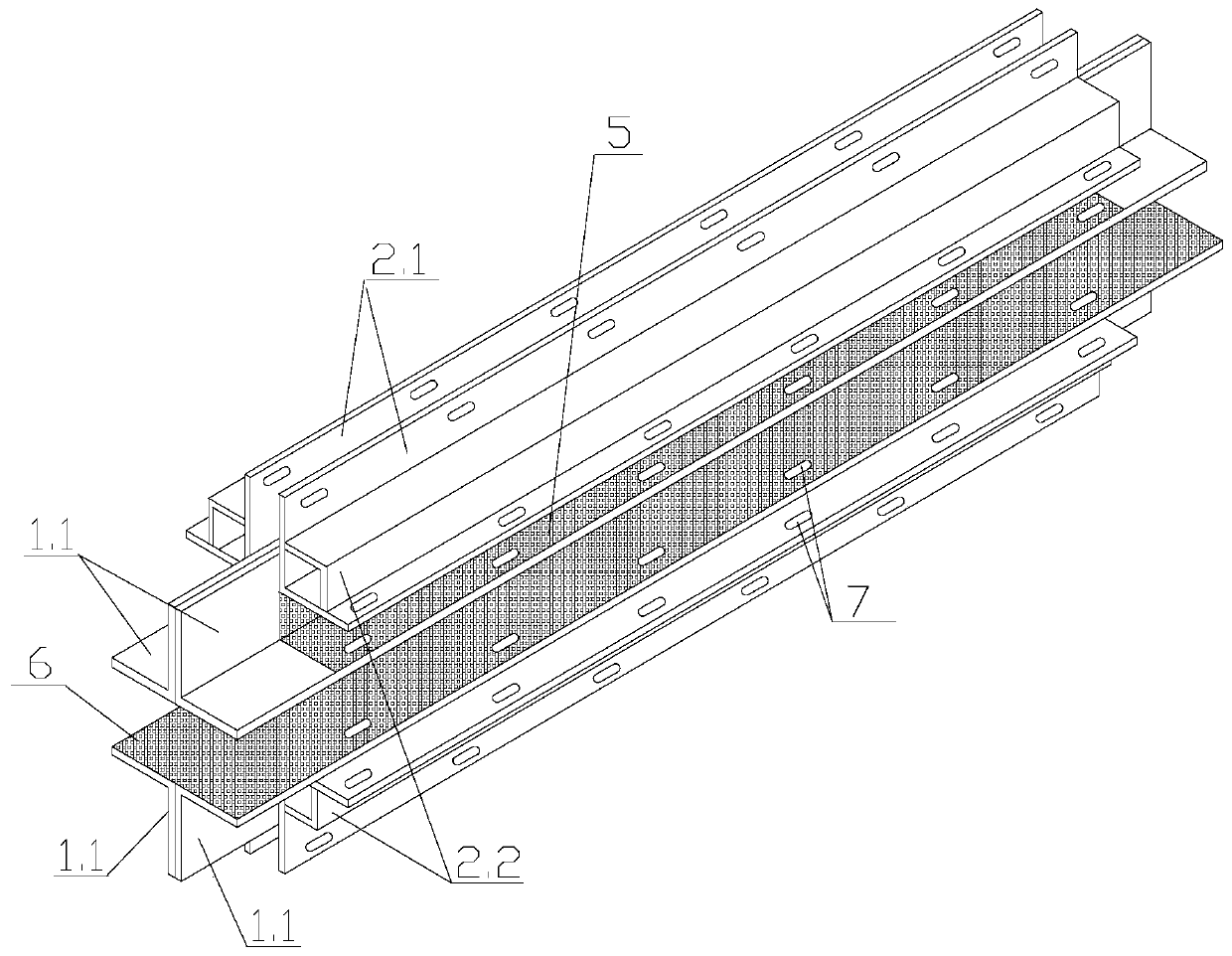

[0034] Such as figure 1 , figure 2 As shown, a cross-section fully assembled anti-buckling support member of the present invention includes a cross-shaped inner core member 1 located in the center, which is respectively arranged in four right-angled angles of the cross-shaped inner core member 1 to form peripheral restraint units. Four constrained square steel pipe assemblies 2, the edges of each two adjacent constrained square steel pipe assemblies 2 and the wing plates 1.2 of the cross-shaped core member 1 sandwiched between the edges of the two constrained square steel pipe assemblies 2 are fixed to each other by bolt assemblies 3 For connection, the pretightening force of the bolt assembly 3 is applied to connect the four constrained square steel pipe assemblies 2 into a stressed whole to form the per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com