Sizing stand of main engine seat for manufacturing seamless steel tube

A seamless steel pipe and sizing machine technology, applied in the direction of metal rolling mill stand, metal rolling stand, metal rolling, etc., can solve the problems of complex shape, inconvenient manufacturing and processing, long processing cycle, etc., and achieve convenient installation , The effect of convenient and reliable processing and manufacturing, and easy processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

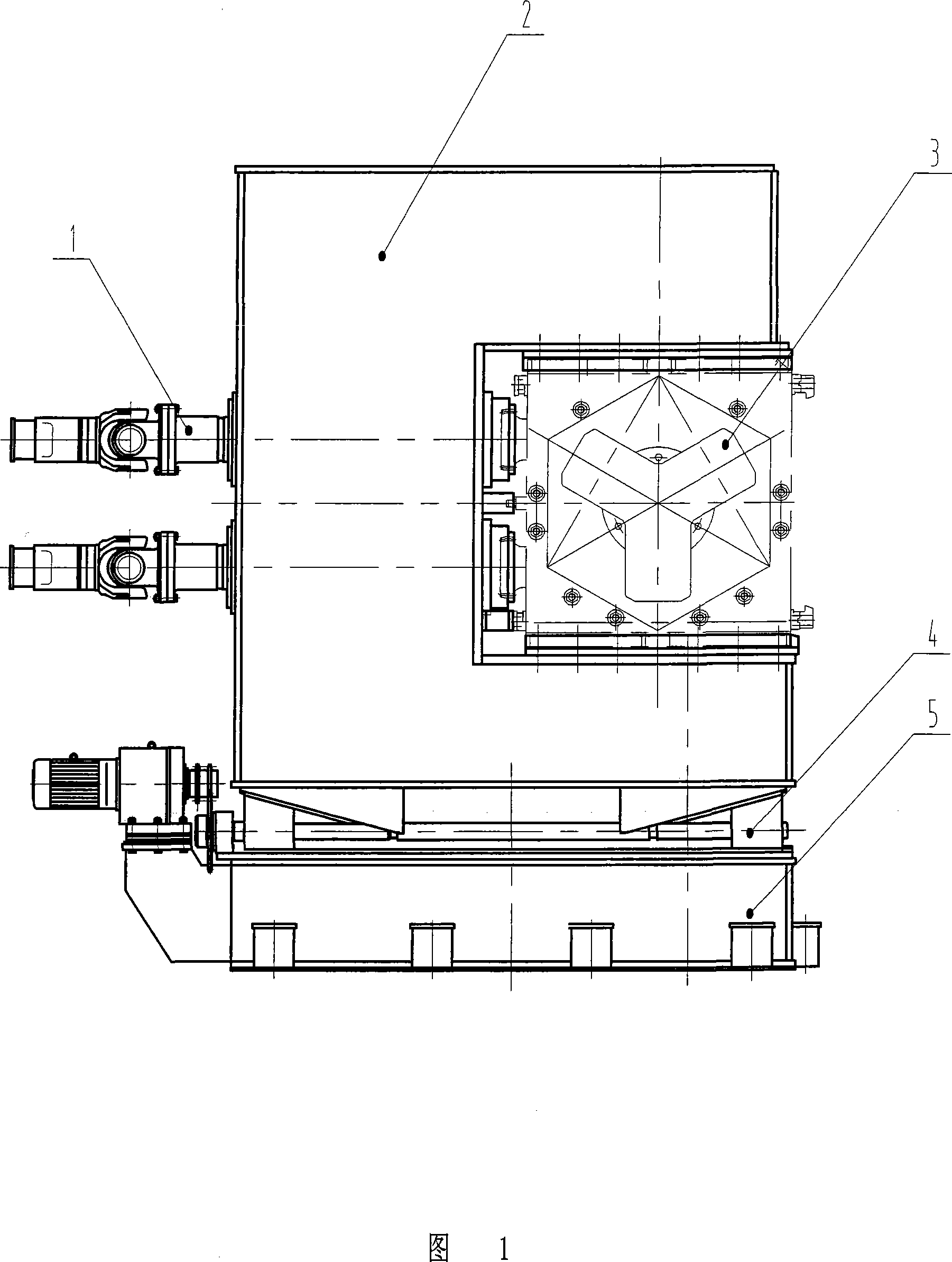

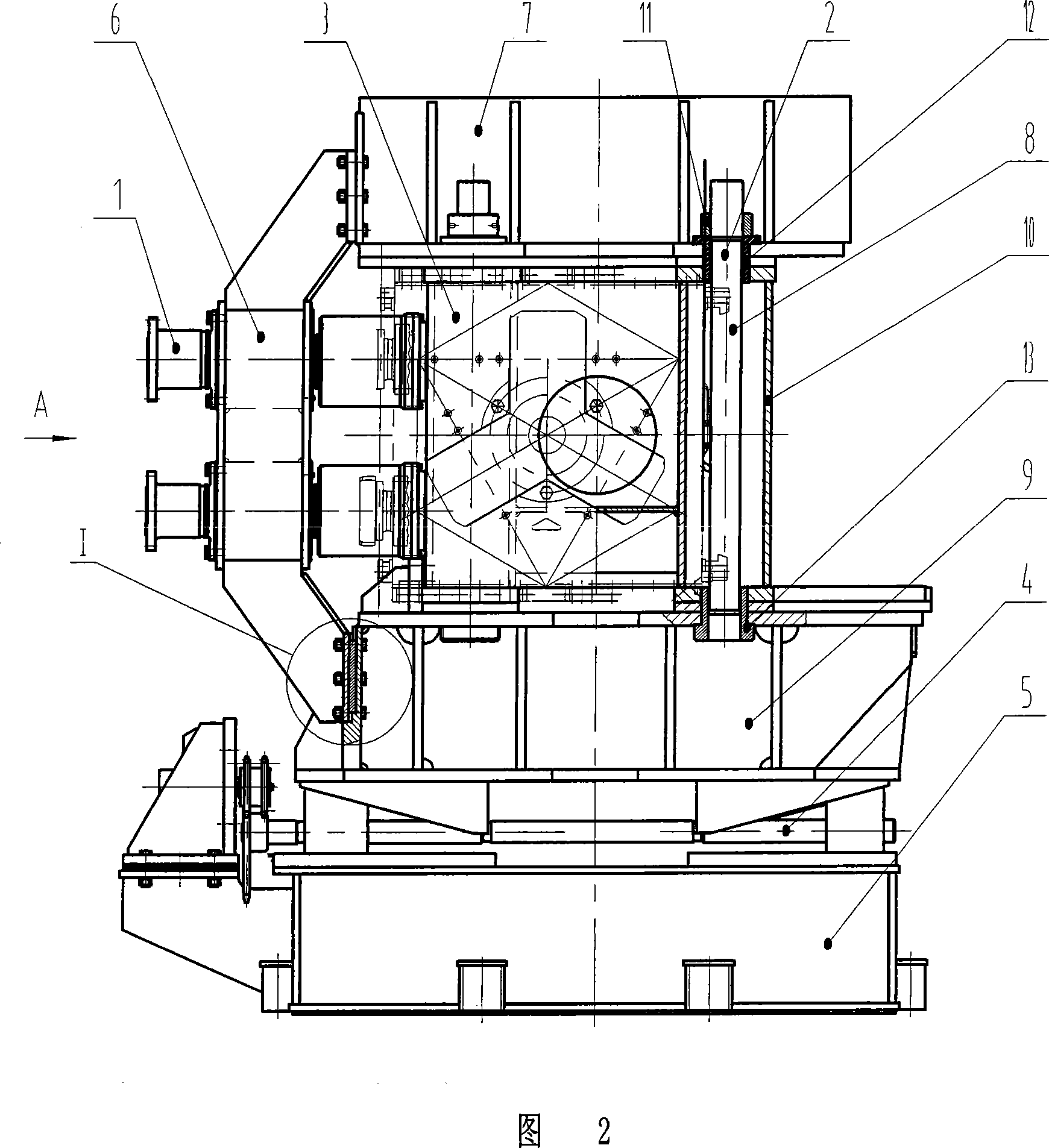

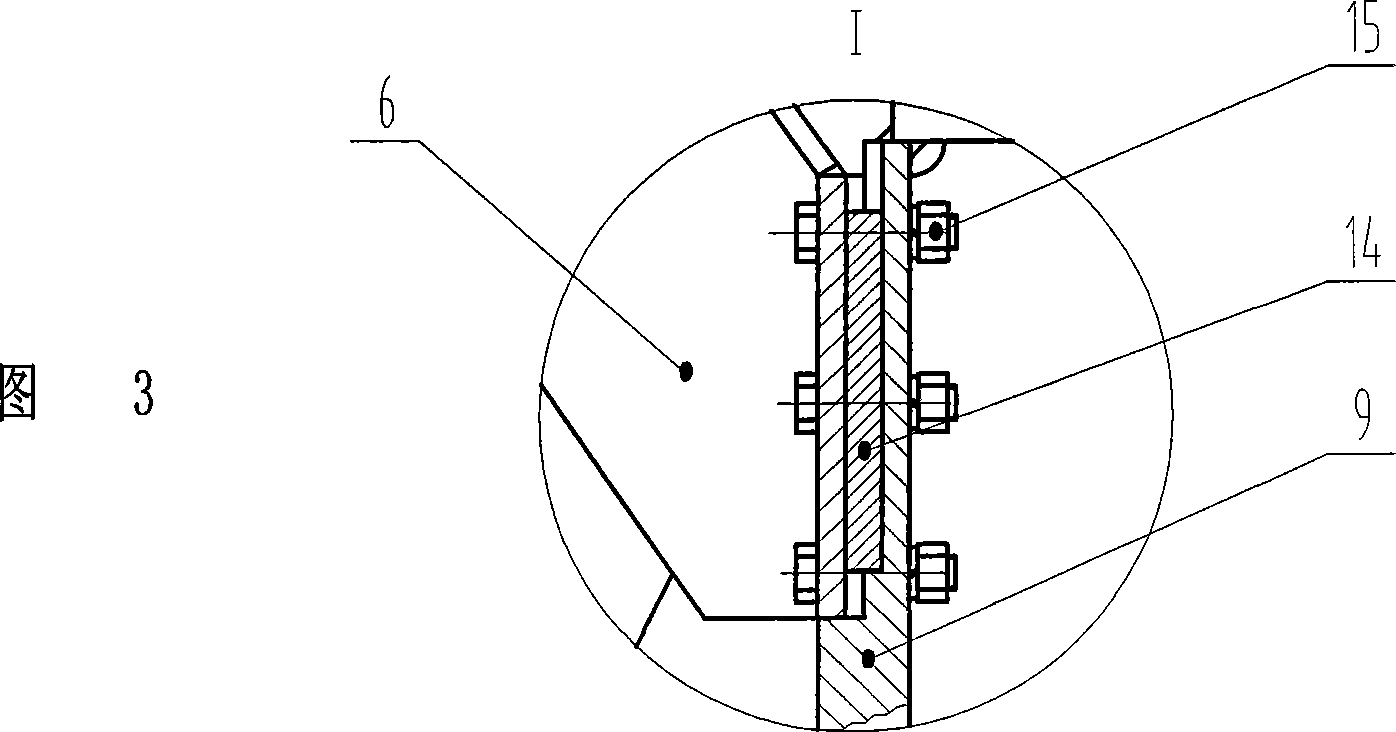

[0018] As shown in Figures 2 and 3, the lower machine base 9 is installed on the base 5 through the lifting adjustment device 4, and the upper beam 7 is supported by two cuboid supporting arches 10, and is installed on four screw rods 8 phases in the supporting arches. Connection, the side support 6 for installing the transmission shaft device 1 is connected with the upper beam 7 and the lower machine base 9 through the bolt group 15, and a flat key 14 is installed at the joint between the side support 6 and the lower machine base 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com