Making method of hawsepipe for single point mooring buoy main body

A single-point mooring and production method technology, which is applied in the production field of anchor chain barrels, can solve the problems of unguaranteed product accuracy, large volume and weight of anchor chain barrels, and inconformity with processing accuracy, etc., and achieves simple structure, reduced processing costs, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

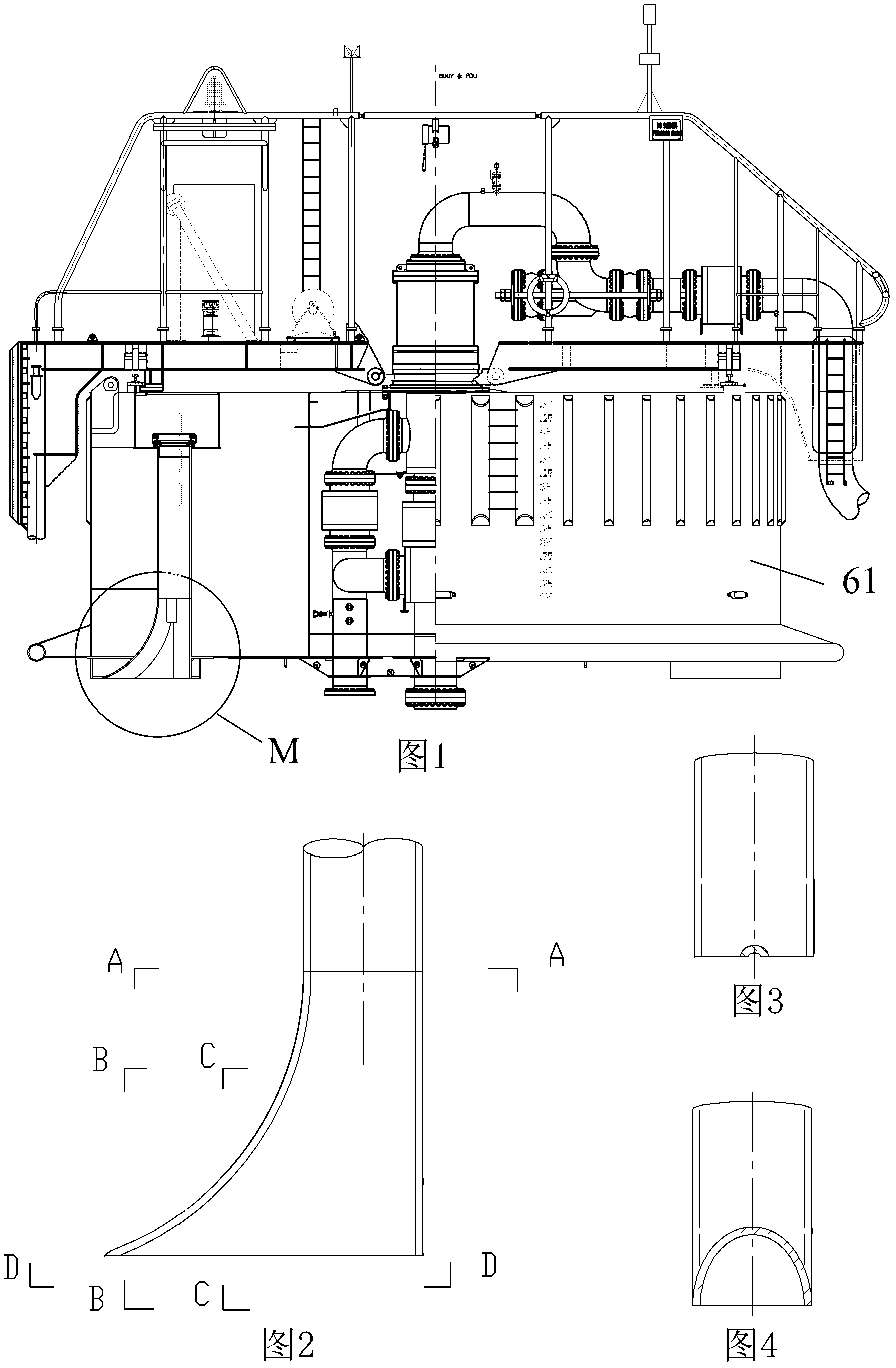

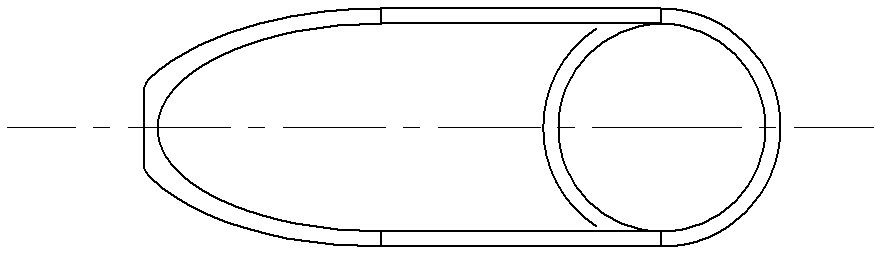

[0031] Such as figure 2 As shown, the anchor chain of the mooring buoy enters the seabed through a tubular structure called a hawse barrel. The anchor chain barrel is generally composed of two parts, namely the straight pipe section and the saddle section.

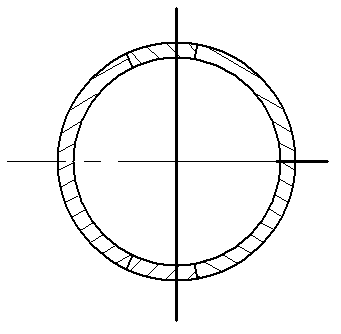

[0032] Such as Figure 3-8 Shown, specifically the anchor chain tube includes an upper cylinder 5 and a lower saddle-shaped structure. Wherein, the saddle-shaped structure includes a semi-straight pipe 3 on one half, an arc-shaped triangular plate 2 and an elbow 1 on the other half and spliced with the side end surface of the semi-straight pipe. The lower part of the saddle-shaped structure is horizontally embedded with an embedded bottom plate 6 and an embedded plate 8 , and between the embedded bottom plate 6 and the embedded plate 8 is provided with reinforcing ribs 9 in a criss-cross manner and peripheral vertically arranged hoardings 7 . In addition, transitional arc plates 4 are also provided on both sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com