Linear dispersion combined prism optical splitter

A prismatic beam splitting and prism technology, applied in prisms, optical components, optics, etc., can solve the problems of OASIS system dispersion nonlinear defects that have not been well improved, difficult key parameters, and increased system assembly and adjustment difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

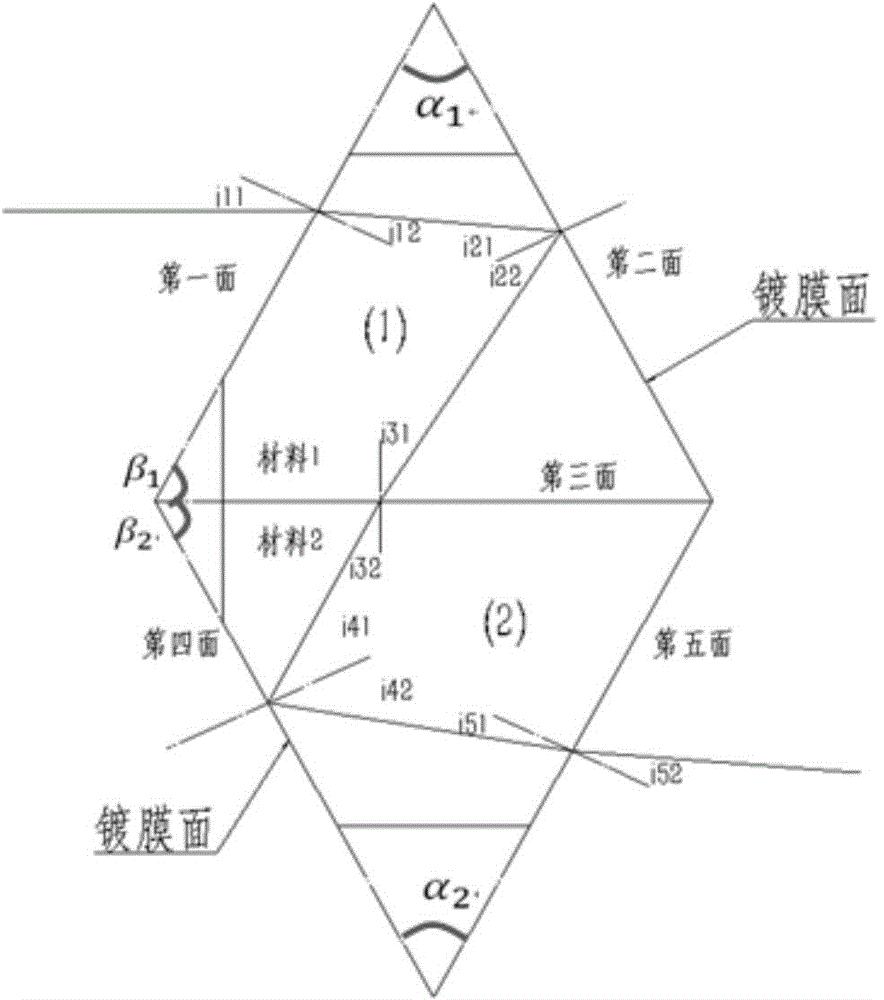

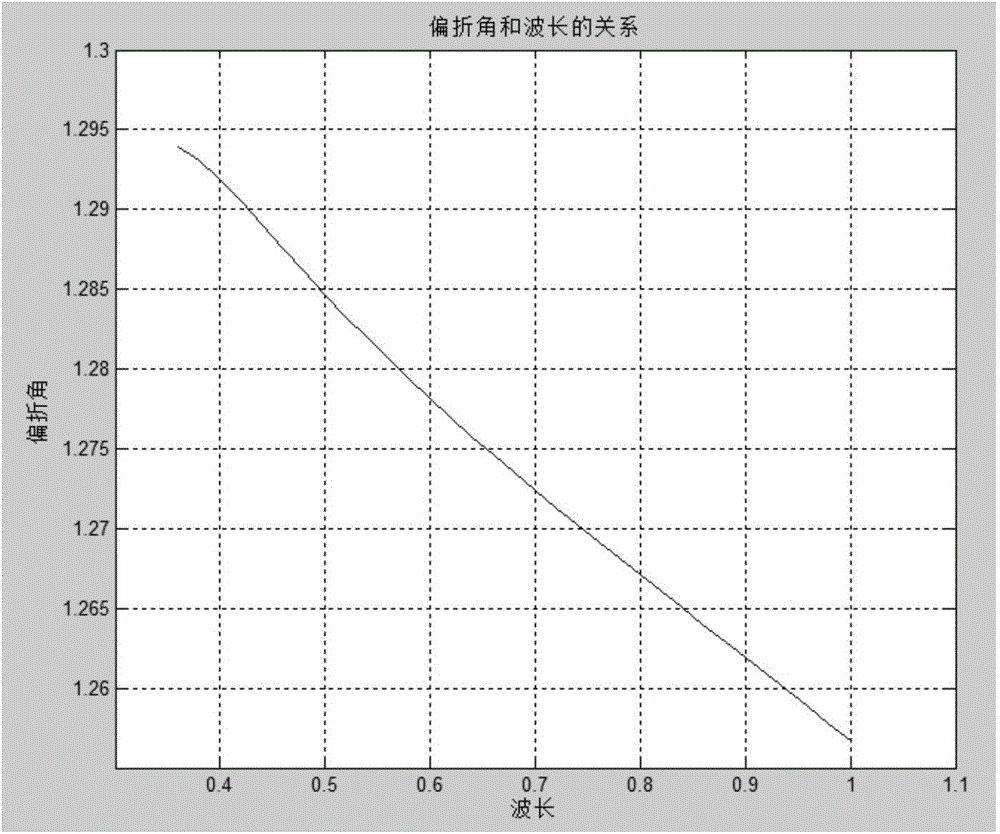

[0061] Embodiment 1: Linear dispersion combined prism spectroscopic device for visible and near-infrared bands

[0062] The present invention adopts following main devices:

[0063] 1. Upper prism 1: material H-BaK5, apex angle 30°, lower bottom side length 40mm, three sides polished, one side aluminum-plated protective film at360-1000nm.

[0064] 2. Lower prism 2: material H-ZK3, apex angle 30°, lower bottom side length 40mm, three sides polished, one side aluminum-plated protective film at360-1000nm.

[0065] The main working principle of the present invention is as figure 2 Expressed by:

[0066] 1. The material refractive index expression is:

[0067] The coefficients of H-BaK5 are B=0.013404, C=0.0148432; the coefficients of H-ZK3 are B=0.0136465, C=0.013476. The second coefficient of the two materials differs by 1.8%, and the third coefficient differs by 9.2%. The upper prism 1 and the lower prism 2 are combined into a combined prism according to the method of "th...

Embodiment 2

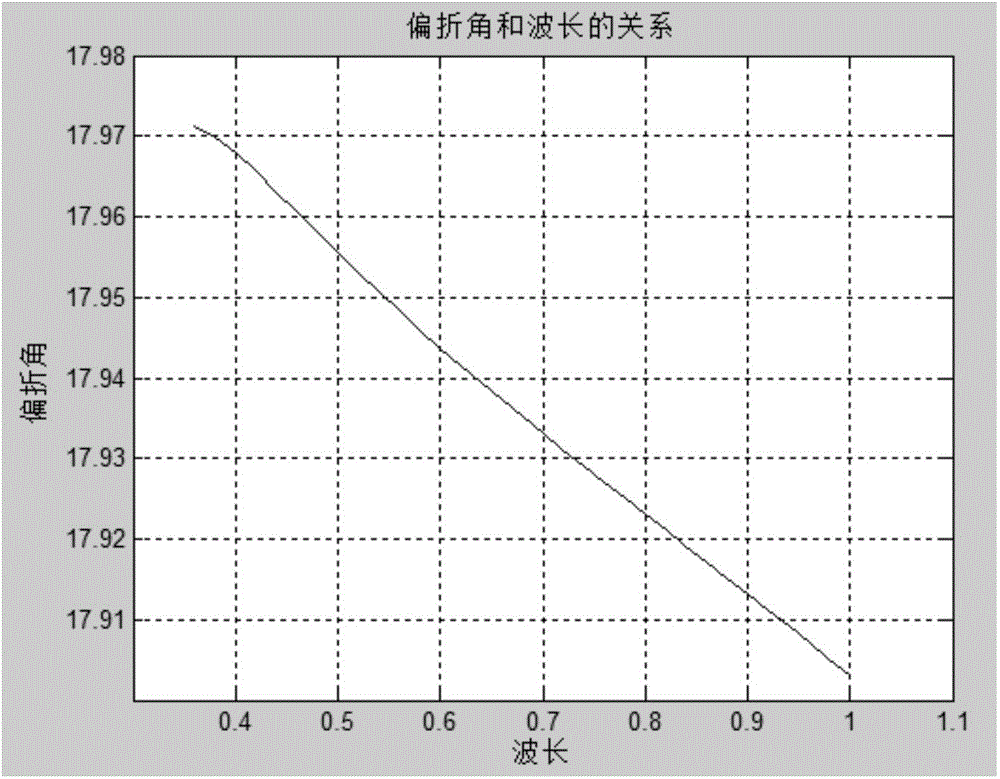

[0070] Embodiment 2: Linear dispersion combined prism spectroscopic device for short-wave infrared band

[0071] The present invention adopts following main devices:

[0072] 1. Upper prism 1: material S-BAL3M, apex angle 27°, lower bottom side length 40mm, three sides polished, one side aluminum-plated protective film at1000-2100nm.

[0073] 2. Lower prism 2: material S-BAL41M, apex angle 27°, lower bottom side length 40mm, three sides polished, one side aluminum-plated protective film at1000-2100nm.

[0074] The main working principle of the present invention is as figure 2 Expressed by:

[0075] 1. The material refractive index expression is:

[0076] The coefficients B=0.0202019, C=0.0236648 of S-BAL3M, the coefficients B=0.0202027, C=0.023359 of S-BAL41M, the second coefficient of the two materials differs by 0.004%, and the third coefficient differs by 1.2%. The upper prism 1 and the lower prism 2 are combined into a combined prism according to the mode of "the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com