Manufacturing method of circular tube through box girder steel member and its steel member structure

A manufacturing method and technology of steel components, applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., can solve problems such as difficulty in adapting to the diversified development of structural components, affecting the safety of building structures, and unscientific manufacturing methods, etc., to achieve shortening The effect of production cycle, good operability, and convenient processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

[0041] Referring to the accompanying drawings, it can be seen that the manufacturing method of the circular tube penetrating box girder steel member is characterized in that it comprises the following steps:

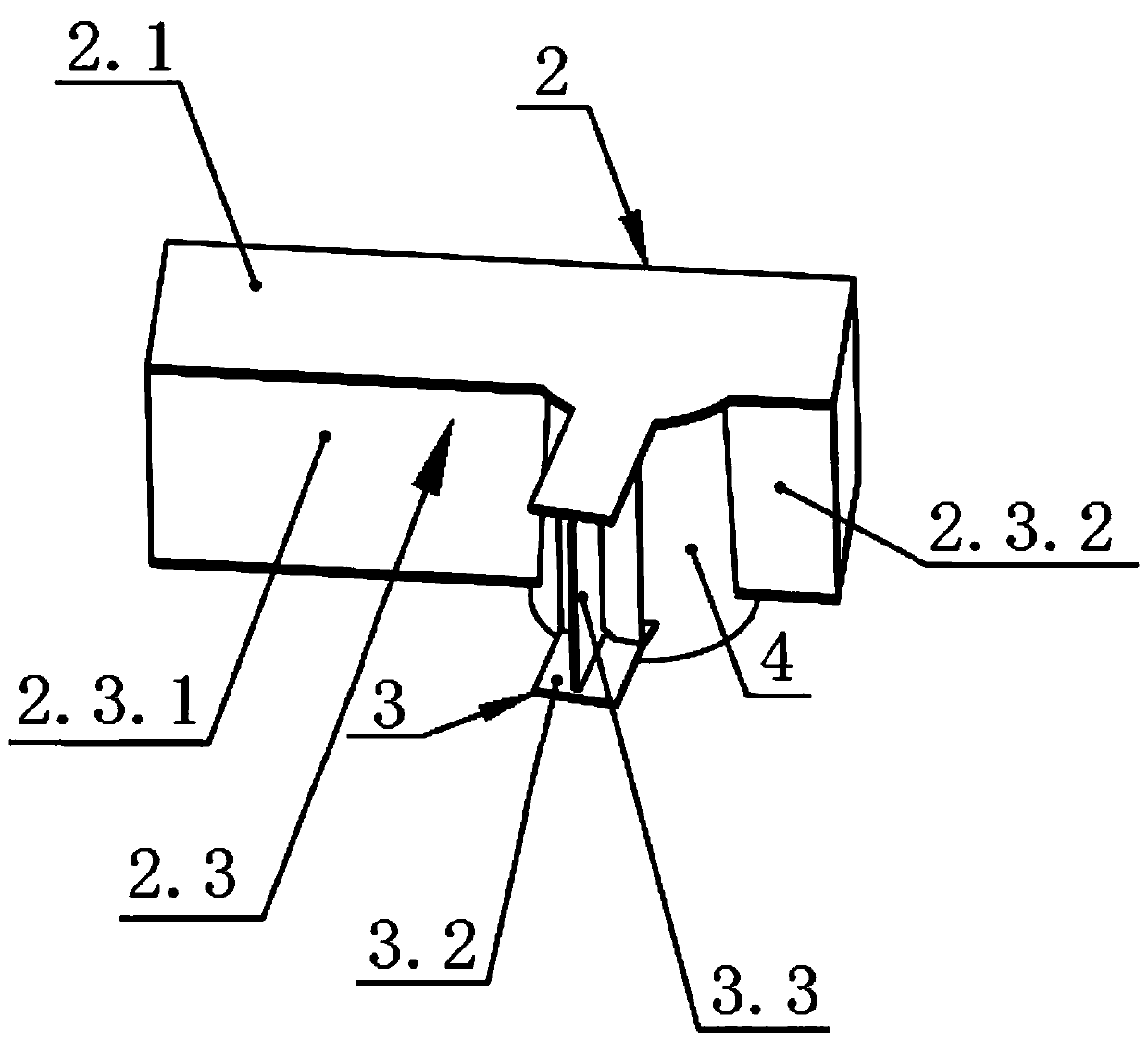

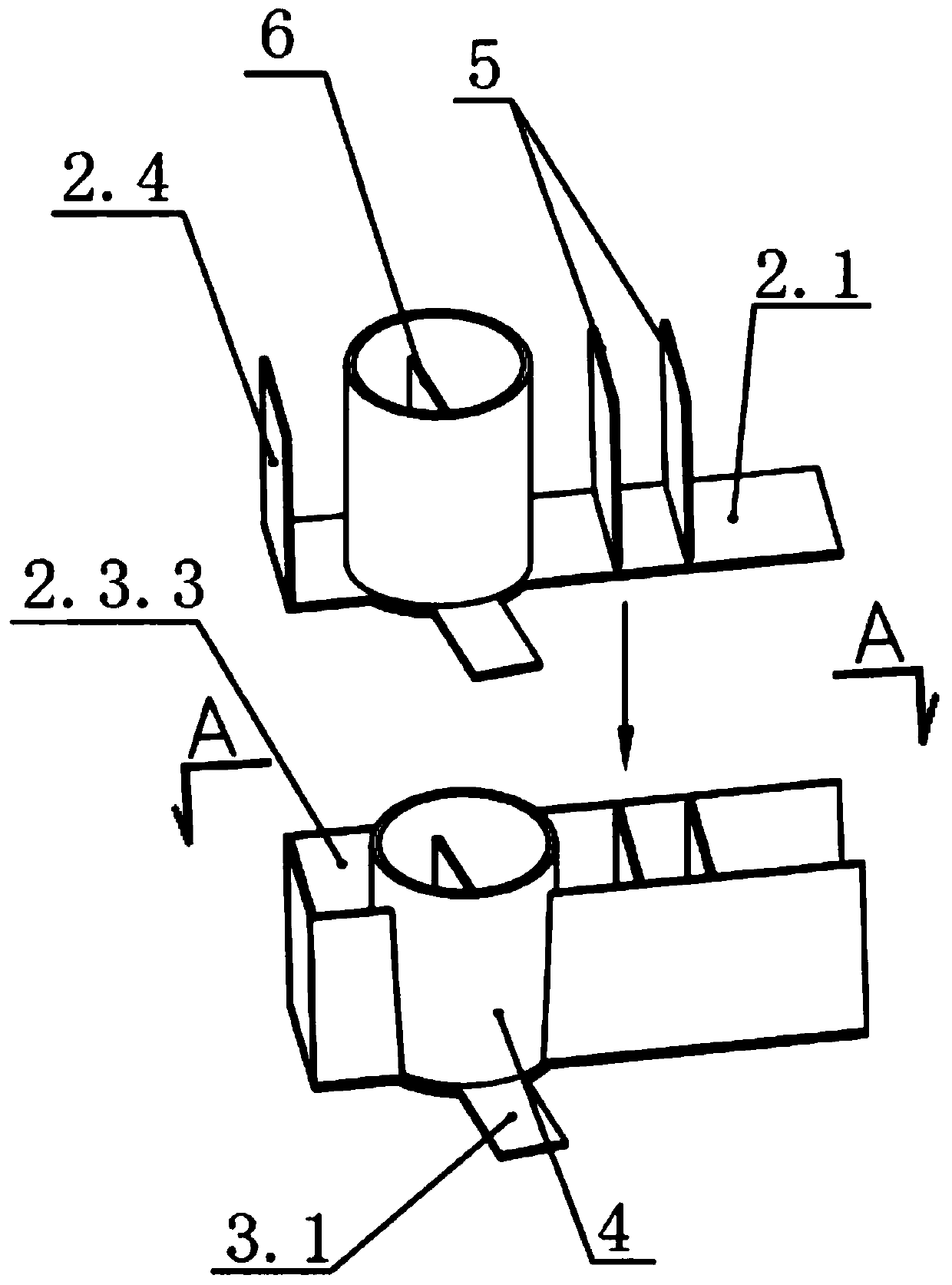

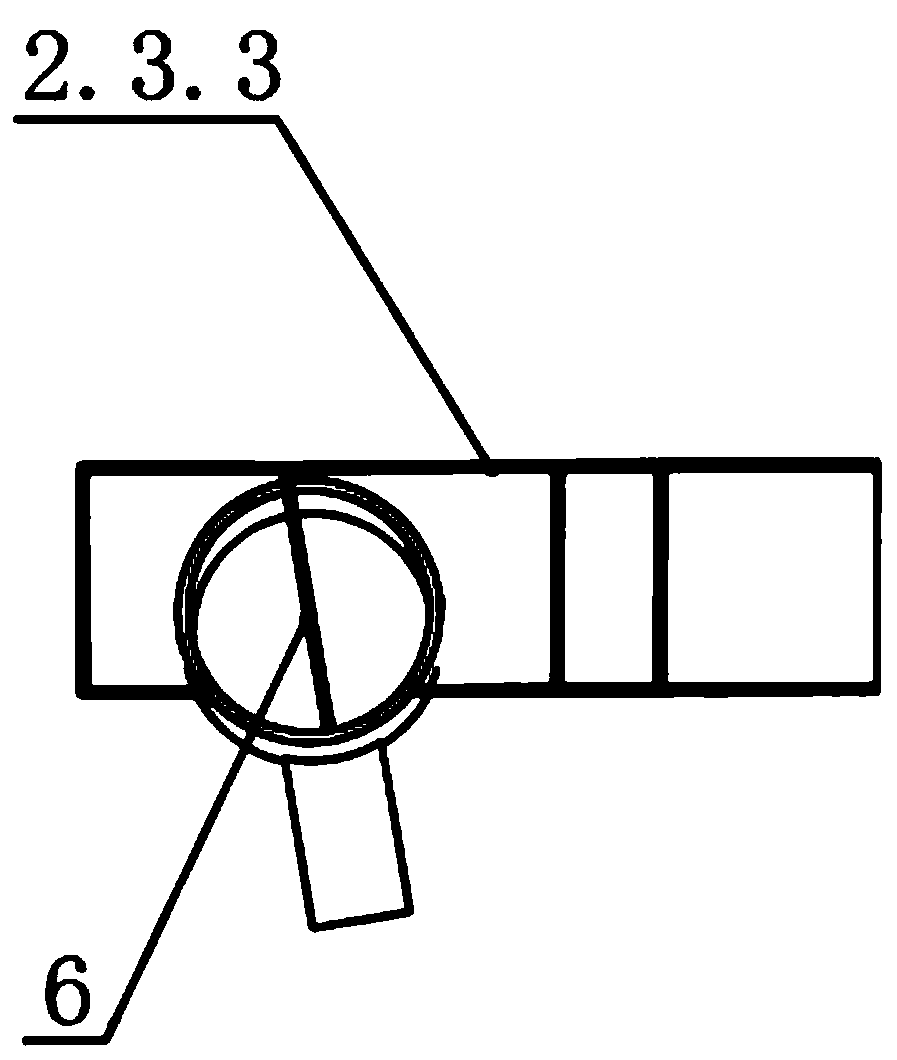

[0042] Step 1: Assemble the box-shaped upper flange plate with the first box-shaped web, the second box-shaped web, the third box-shaped web, the inner partition of the circular tube, and the node circular tube: the box-shaped upper flange plate 2.1 Lay it flat, assemble the first box-shaped web 2.3.1 and the second box-shaped web 2.3.2 on the lower end of one side of the box-shaped upper flange plate 2.1, and assemble the third box-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap