A kind of mica sheet skeleton

A technology of mica sheet and frame, which is applied in the field of mica sheet frame, can solve the problems of high requirements for welding workers, poor installation process, and high difficulty, and achieve the effects of avoiding abnormal fusing, reliable connection quality, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solution of the present invention, its specific implementation will be described in detail below in conjunction with the accompanying drawings:

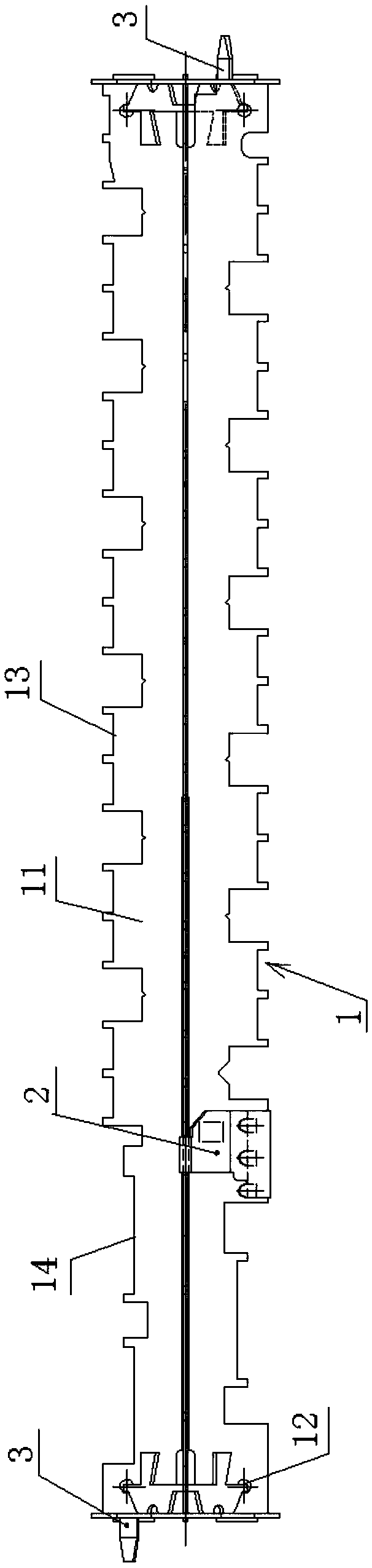

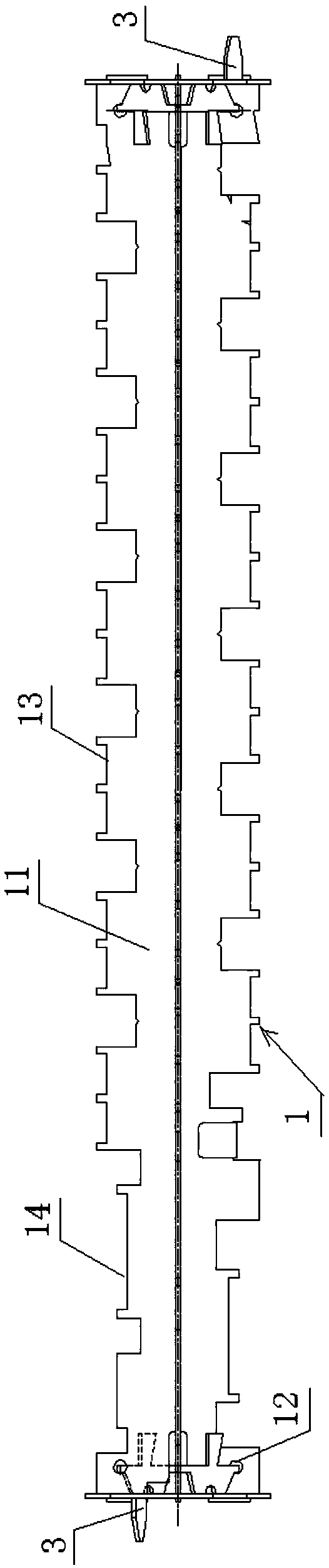

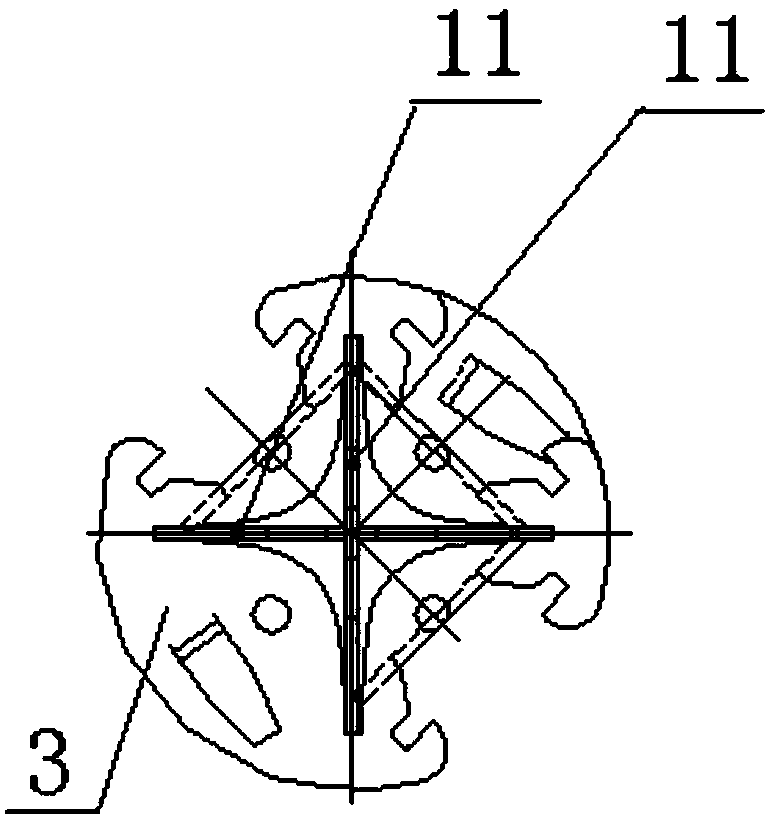

[0033] see figure 1 , figure 2 and image 3 , The best embodiment of the present invention, a mica sheet skeleton, including a skeleton body 1, a connector 2 and two contact plates 3. The axial cross-section of the skeleton body 1 is in the shape of a cross, and the skeleton body 1 is formed by connecting four mica sheets 11, and the left and right ends of each mica sheet 11 are respectively provided with tentacles engaging holes 12, and each mica sheet 11 is provided with Fuse card slot 13 and fuse card slot 14. The two contact plates 3 are arranged on the two axial ends of the skeleton body 1 in one-to-one correspondence, and the connecting piece 2 is arranged between two adjacent mica sheets 11 of the skeleton body 1 .

[0034] see Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com