Grinding method and system

A technology of grinding and mold repairing, which is applied in the direction of grinding machine, grinding feed movement, grinding workpiece support, etc., and can solve the problems of damage to the electric spindle and no grinding system

Active Publication Date: 2019-05-07

CRRC TANGSHAN CO LTD

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

If the frame is simply ground according to the preset fixed program and trajectory, for high weld seams, the manipulator is likely to damage the electric spindle due to excessive feed in the early stage of grinding; In the initial stage of grinding, the manipulator may not be able to touch the weld seam at all, and only performs idling operation

However, in the prior art, there is no grinding system that can perform different grinding operations according to the shape of different welds and corner areas of the structure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 4

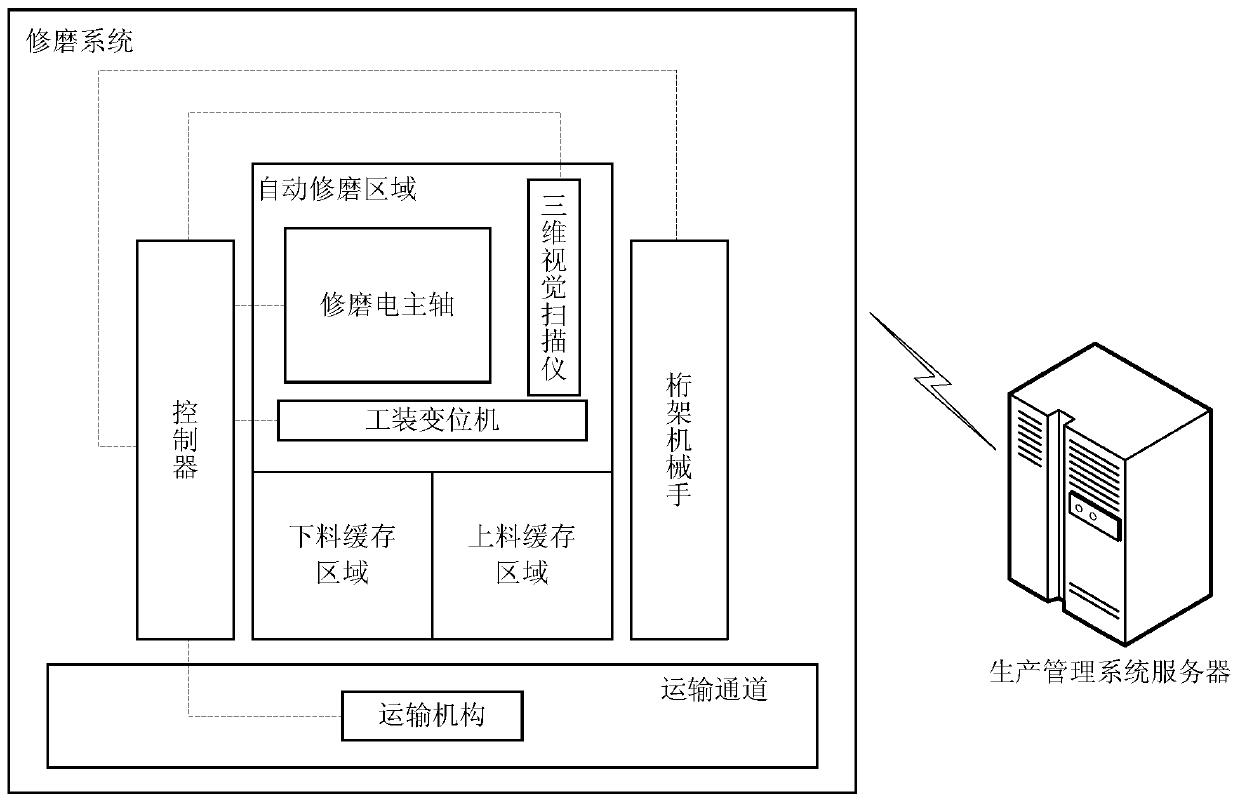

[0126] The grinding system provided in Embodiment 4 can be used to execute the grinding method provided in Embodiment 1 and Embodiment 3 above. The specific implementation and technical effects are similar, and will not be repeated here.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

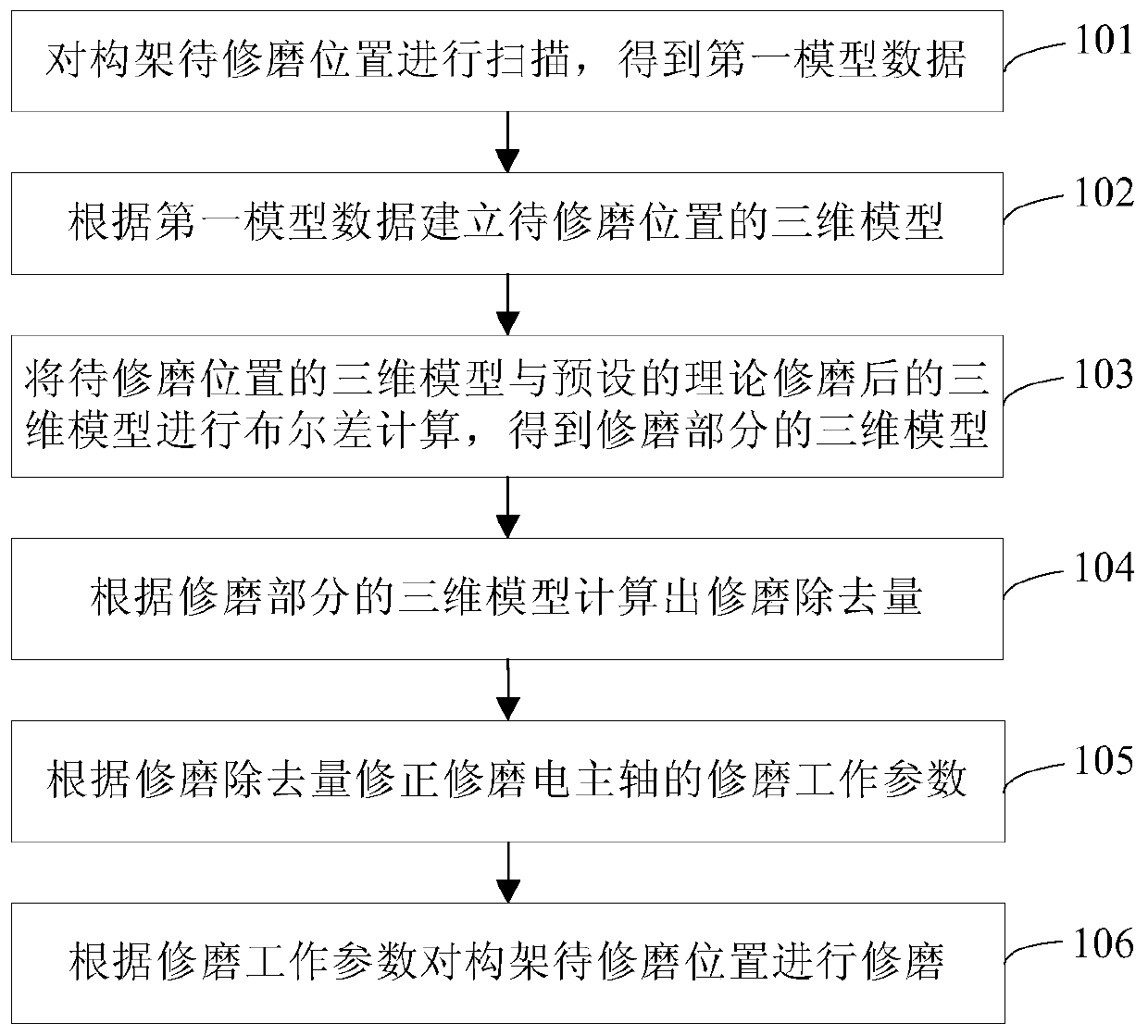

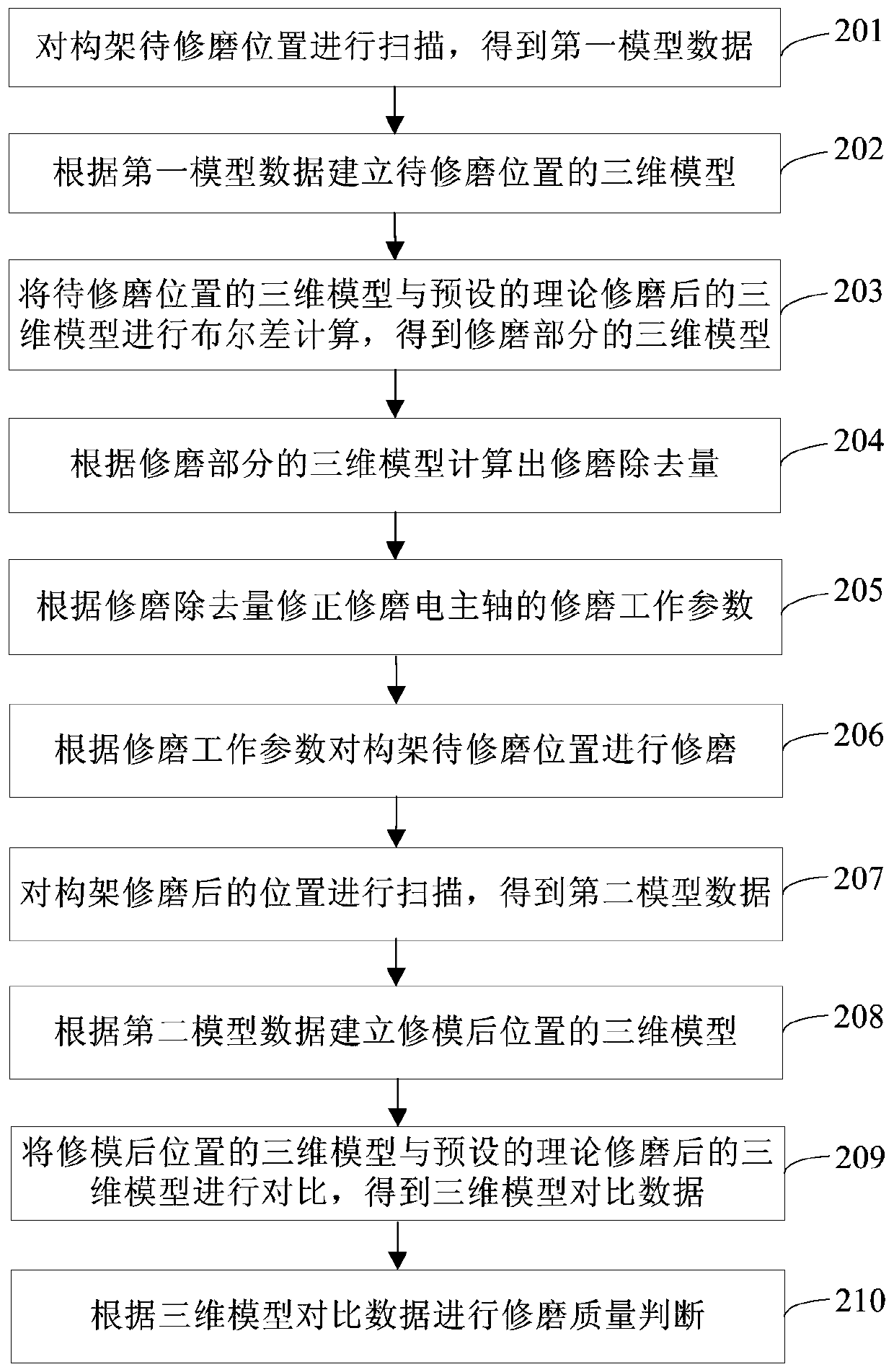

The invention provides a grinding method and system. The method comprises the steps that the to-be-ground position of a framework is scanned, and first model data are obtained; according to the first model data, a three-dimensional model of the position to be ground is built; the three-dimensional model of the position to be ground and the preset three-dimensional model after theoretical grinding are subject to Boolean difference calculation, and the three-dimensional model of the grinding position is obtained; according to the Boolean difference calculation, the portion coinciding with the three-dimensional model after theoretical grinding is subtracted from the three-dimensional model of the position to be ground; according to the three-dimensional model of the grinding position, the grinding removal amount is calculated; according to the grinding removal amount, grinding work parameters of a grinding electric spindle are corrected; according to the grinding work parameters, the to-be-ground position of the framework is ground. By the adoption of the method, to-be-ground positions of different frameworks can be subject to adaptive grinding, and the grinding efficiency is improved whole the grinding quality is ensured.

Description

technical field [0001] The invention relates to mechanical manufacturing technology, in particular to a grinding method and system. Background technique [0002] The frame is the skeleton of the rail vehicle bogie, and it is mostly welded by steel plates and forged castings. The welds and corner areas of the welded parts need a lot of grinding and shaping, so that the welds can be smoothly transitioned to improve the overall structure. fatigue life. [0003] The patent application number CN201620972238.5 discloses an automatic bogie frame assembly system, wherein the manipulator for grinding operation grinds the frame according to the preset fixed program and track. However, in reality, the weld seam and corner geometry formed by each frame after welding will be slightly different, for example, some weld seam heights are higher and some weld seam heights are lower. If the frame is simply ground according to the preset fixed program and trajectory, for high weld seams, the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B24B9/04B24B41/00B24B27/00B24B41/06B24B49/12G05B19/04

CPCB24B9/04B24B27/0023B24B41/005B24B41/06B24B49/12G05B19/04

Inventor 卢峰华宋学毅姜斌李蕊张文朝崔岩安博臧宗波刘国田魏灿

Owner CRRC TANGSHAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com