Intelligent mortar mixing device

A mortar mixing and intelligent technology, which is applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of manual water addition, poor mortar mixing effect, and difficult control of mortar consistency, etc., and achieve the effect of accurate consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

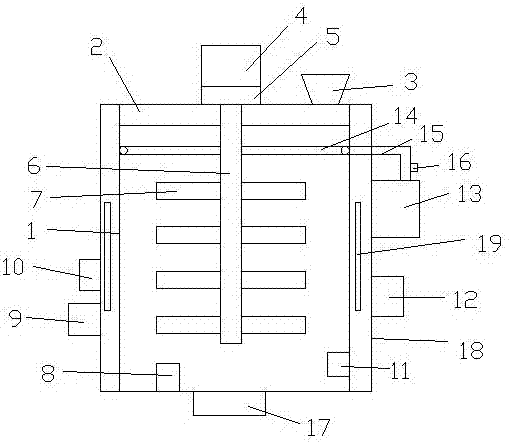

[0023] figure 1 The intelligent mortar mixing device shown includes an inner cylinder body, an outer cylinder body, and a cover plate arranged on the top of the outer cylinder body. Connect the rotating shaft, the rotating shaft extends into the inner cylinder through the cover plate, several stirring rods are detachably connected to the rotating shaft, the inner wall of the inner cylinder is provided with a pressure sensor, a consistency sensor, and a spray pipe, and the outer wall of the outer cylinder is provided with There are a first controller, an alarm device, a second controller, and a water tank. The spray pipe is connected to the water tank through a connecting pipe, and an electric control valve is arranged on the connecting pipe. The pressure sensor and the alarm device are respectively connected to the first controller The consistency sensor and the electric control valve are respectively connected to the second controller, the bottom of the inner cylinder is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com