Rotary corrugated piece sucking mechanism of paper cup or paper bowl sleeving machine

A technology of corrugated sheets and paper bowls, which is applied in the field of paper cup or paper bowl jacket machine rotary suction corrugated sheet mechanism, which can solve the problems of easy falling, difficulty in sucking the suction nozzle, and affecting production efficiency, so as to achieve not easy falling, high production efficiency Improvement and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

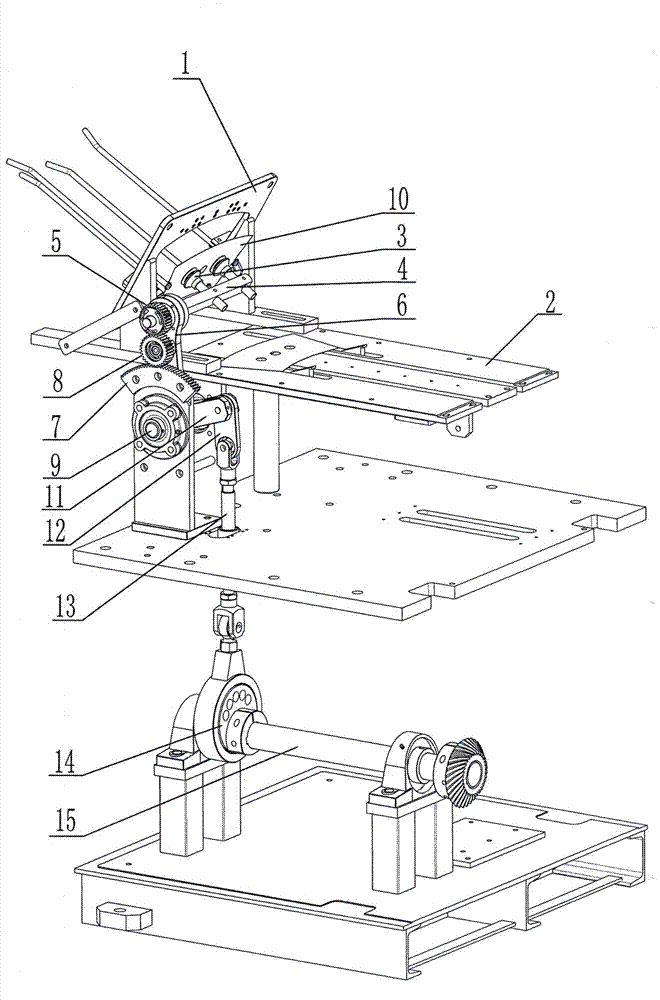

[0010] Referring to the accompanying drawings, the paper cup or paper bowl overcoat machine rotates the corrugated sheet suction mechanism, including a paper frame 1 and a paper-feeding panel 2. The paper frame 1 is arranged obliquely above the paper-feeding panel 2, and the corrugated sheet is placed on the paper frame 1. 10. The smooth surface of the corrugated sheet 10 faces the paper-feeding panel 2, and a conveying suction nozzle 3 is provided between the paper frame 1 and the paper-feeding panel 2, and the conveying suction nozzle 3 is driven by a rotating paper-absorbing mechanism to convey the corrugated sheet, namely The conveying nozzle sucks the smooth surface of the corrugated sheet and rotates it, and then transfers the corrugated sheet to the paper feeding panel, and the smooth surface of the corrugated sheet on the paper feeding panel faces upward.

[0011] The rotary paper suction mechanism includes a rotary rod 4, a gear 5, a rotary swing arm 6, a fan-shaped ra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap