Transverse sealing mechanism used on pillow type packaging machine and pillow type packaging machine

A pillow packaging machine and horizontal sealing technology, which is applied in the directions of packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problems of slow packaging speed, inflexible adjustment, troublesome maintenance, etc., and achieve good cutting and sealing effects, and the overall The effect of simple structure and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

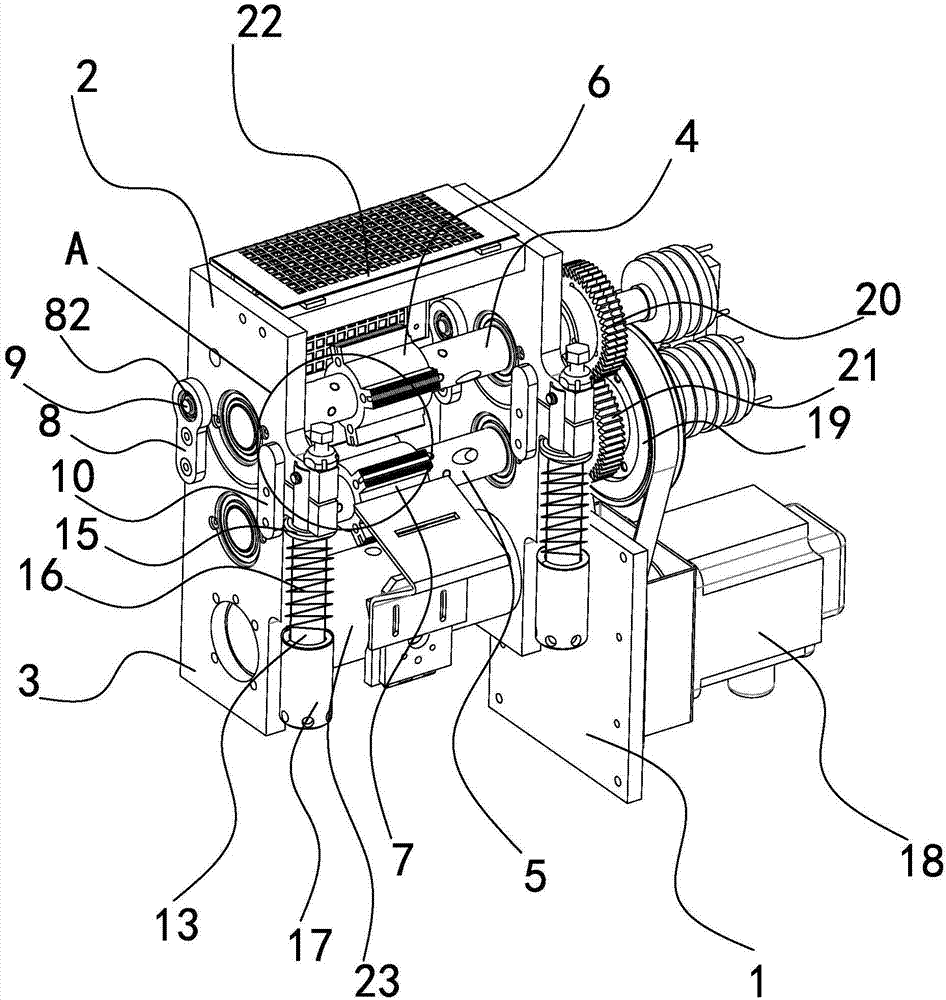

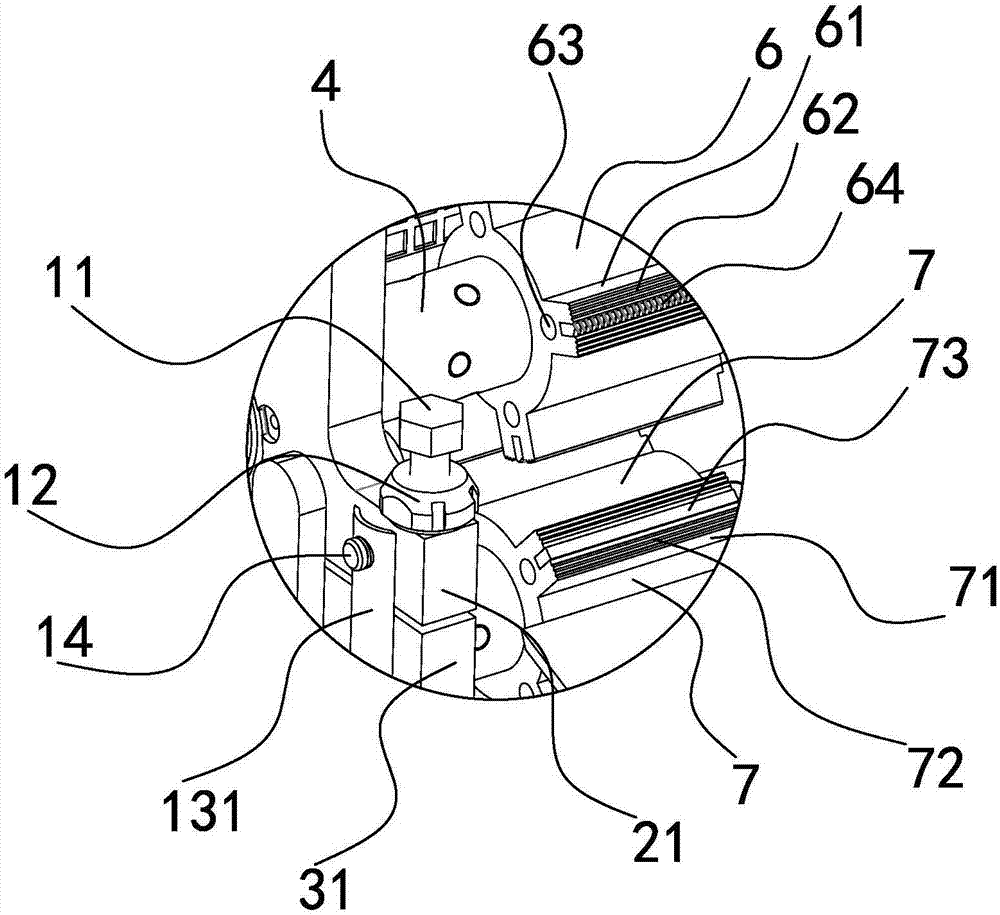

[0028] Such as figure 1 and 2 As shown, the horizontal sealing mechanism used on the pillow packaging machine includes a bracket 1, a horizontal sealing upper shaft 4, a horizontal sealing lower shaft 5, and two support plates and a motor 18 fixedly connected to the bracket 1.

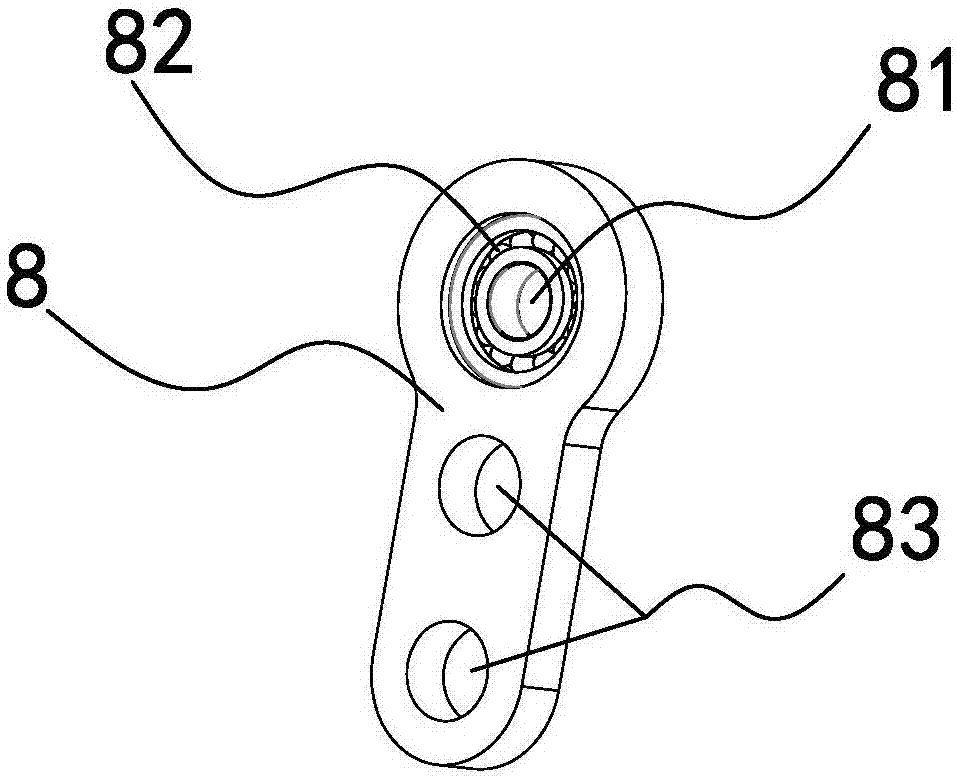

[0029]The support plate is a whole rectangular parallelepiped plate of equal thickness. The support plate is cut from the middle to form an independent floating plate 2 and a fixed plate 3. The middle part of the cutting line is a circular arc, and the two sides are horizontal lines. After assembly, its floating There is a gap between the plate 2 and the fixed plate 3 . Since the floating plate 2 and the fixed plate 3 are cut from the top and bottom of a whole piece of equal thickness support plate, so as long as the floating plate 2 and the fixed plate 3 are facing each other without deviation, it is easier to ensure that the floating plate 2 The upper and lower surfaces of the upper and lower surfa...

Embodiment 2

[0036] A pillow packaging machine is provided, comprising the above-mentioned horizontal sealing mechanism used on the pillow packaging machine. This pillow packaging machine can realize high-speed packaging, and it is more convenient to disassemble and install, so that adjustment and maintenance are more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com