Garbage can

A technology of dustbin and garbage, which is applied in the field of sanitation to achieve the effect of easy separate treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

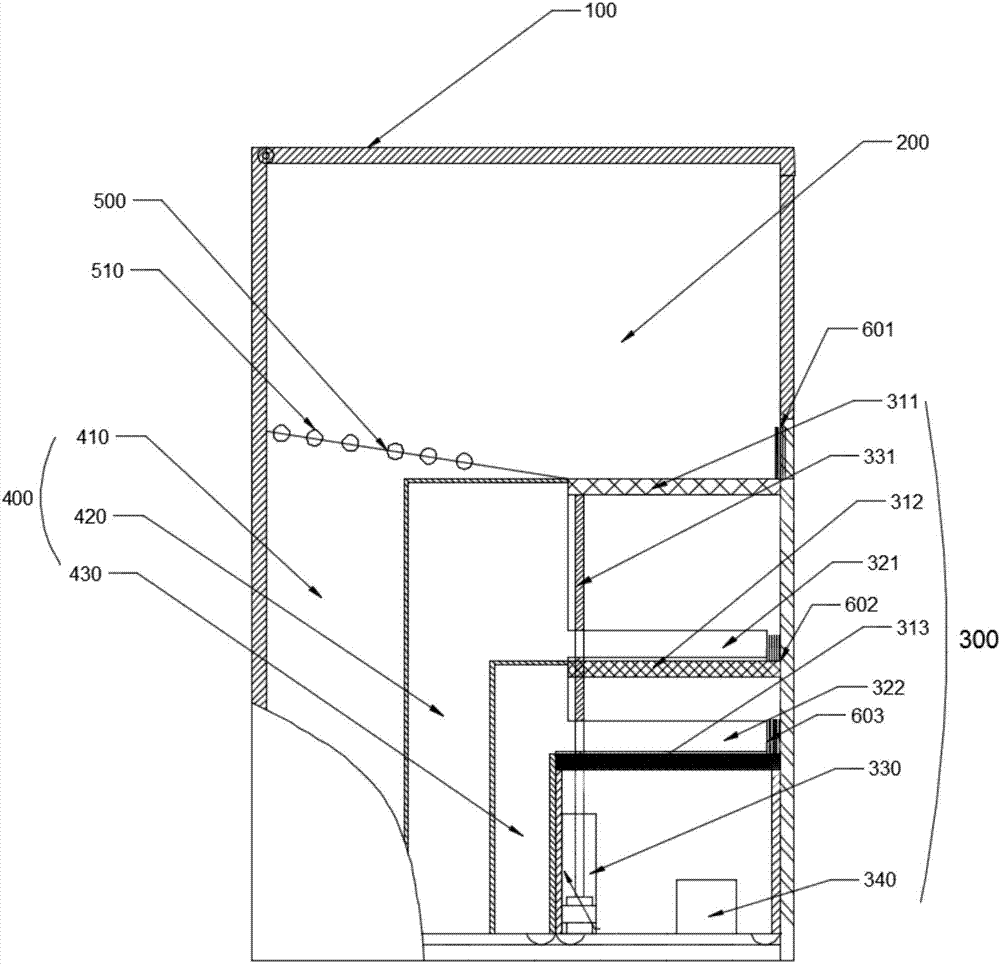

[0027] like figure 1 and image 3 As shown, the present embodiment provides a garbage bin, including a box body 100, and the box body 100 includes an upper filter chamber 200, a lower garbage chamber and a slag extraction port adjacent to the garbage chamber, and the garbage chambers are arranged side by side A liquid collection box 003 and a solid collection box 004 are provided. The inner wall of the box body 100 is provided with a slanted baffle 500. The upper part of the liquid collection box 003 is arranged in parallel with a primary filter 311 and a secondary filter from top to bottom. A net 312 and a third-stage filter screen 313, the upper end of the slag-taking port is provided with a row brush 1 601 in contact with the upper surface of the first-stage filter screen 311.

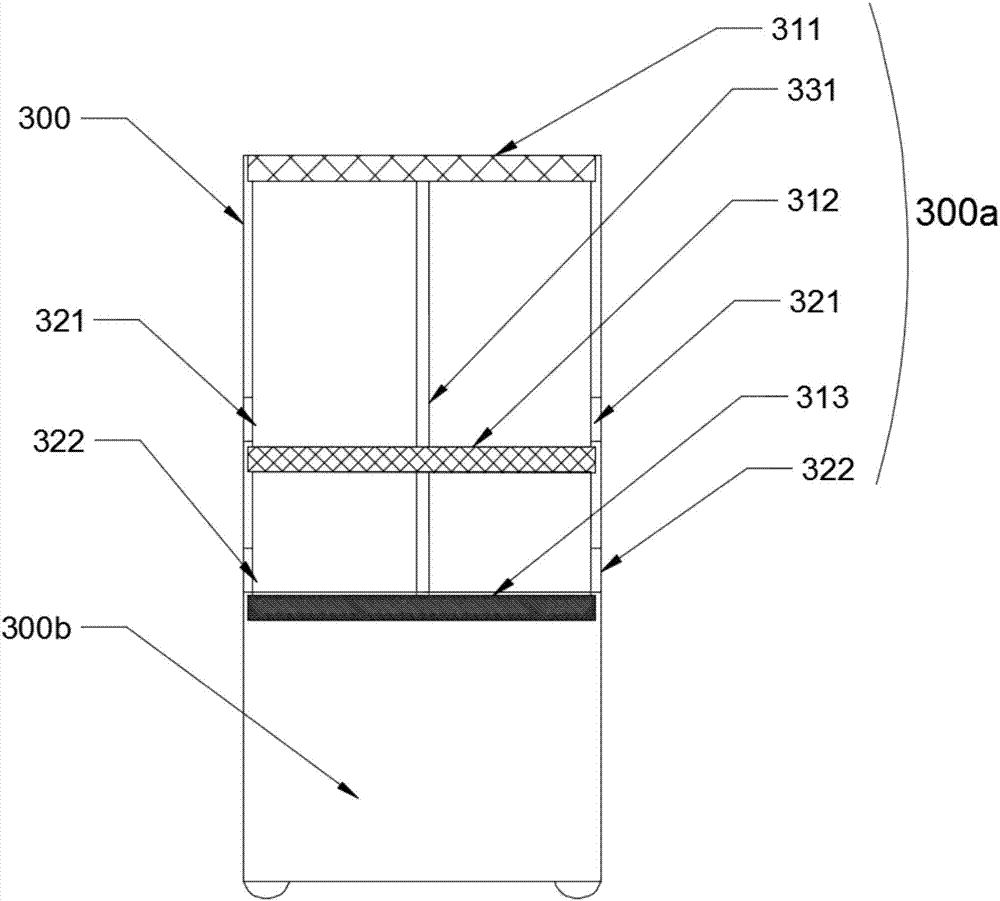

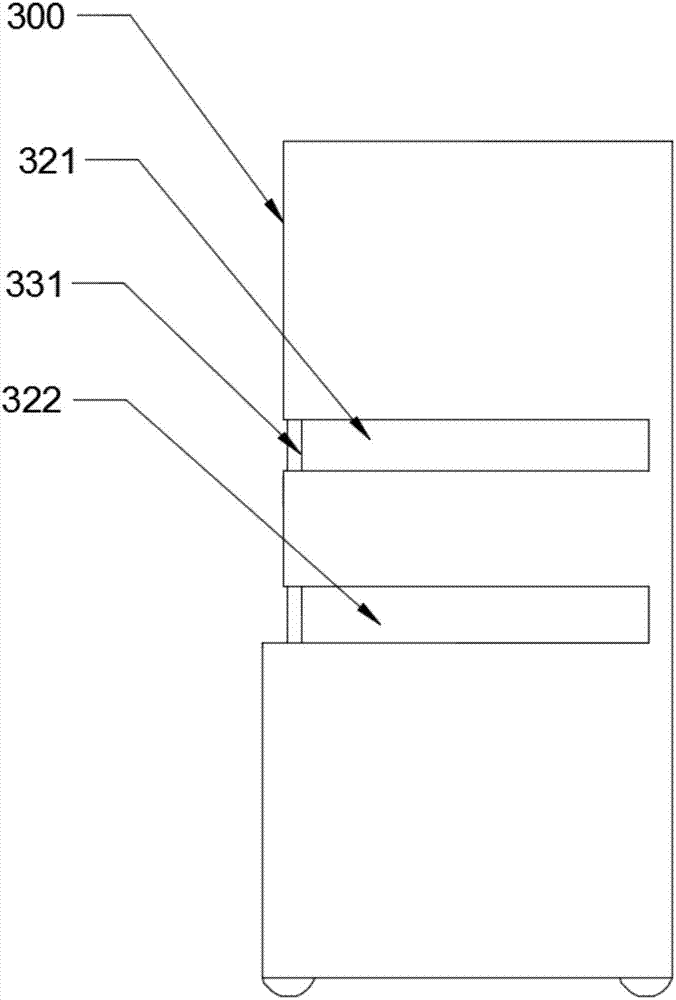

[0028] The liquid collection box 003 includes an upper splint part 300a and a lower liquid garbage box 300b. The left and right sides of the splint part 300a are connected, and three grooves are re...

Embodiment 2

[0034] like figure 1 and image 3 As shown, the present embodiment provides a garbage bin, including a box body 100, and the box body 100 includes an upper filter chamber 200, a lower garbage chamber and a slag extraction port adjacent to the garbage chamber, and the garbage chambers are arranged side by side A liquid collection box 003 and a solid collection box 004 are provided. The inner wall of the box body 100 is provided with a slanted baffle 500. The upper part of the liquid collection box 003 is arranged in parallel with a primary filter 311 and a secondary filter from top to bottom. A net 312 and a third-stage filter screen 313, the upper end of the slag-taking port is provided with a row brush 1 601 in contact with the upper surface of the first-stage filter screen 311.

[0035] The liquid collection box 003 includes an upper splint part 300a and a lower liquid garbage box 300b. The left and right sides of the splint part 300a are connected, and three grooves are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com