Support assembly for dismantling of support beams in foundation pits

A technology for supporting components and supporting beams, applied in infrastructure engineering, construction, excavation, etc., can solve problems such as uncontrollable safety and reliability at the cutting site, unbalanced force on the main body of the inner supporting beam, and increasing the probability of safety accidents. , to achieve the effect of convenient hoisting and transportation, ensuring stability and reducing the probability of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

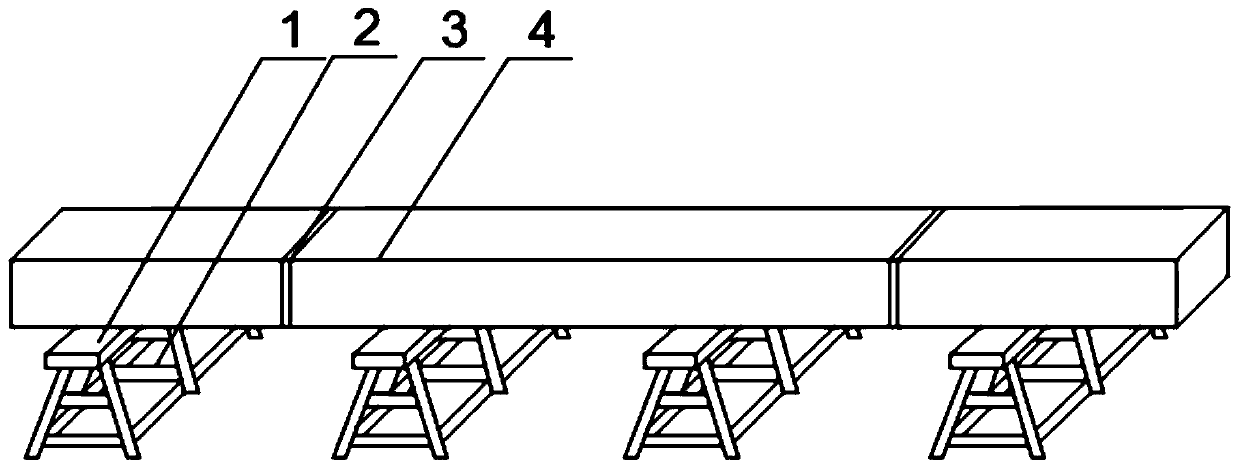

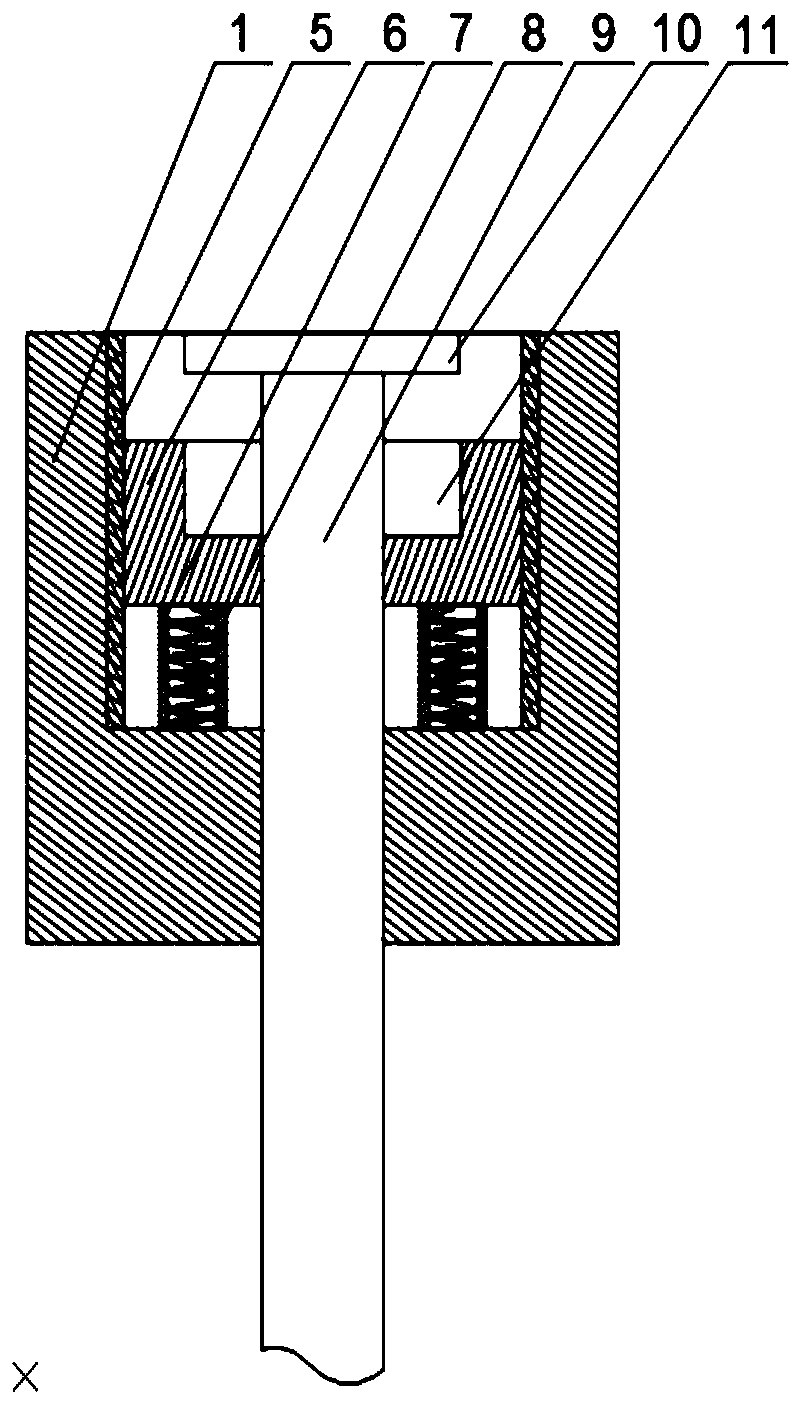

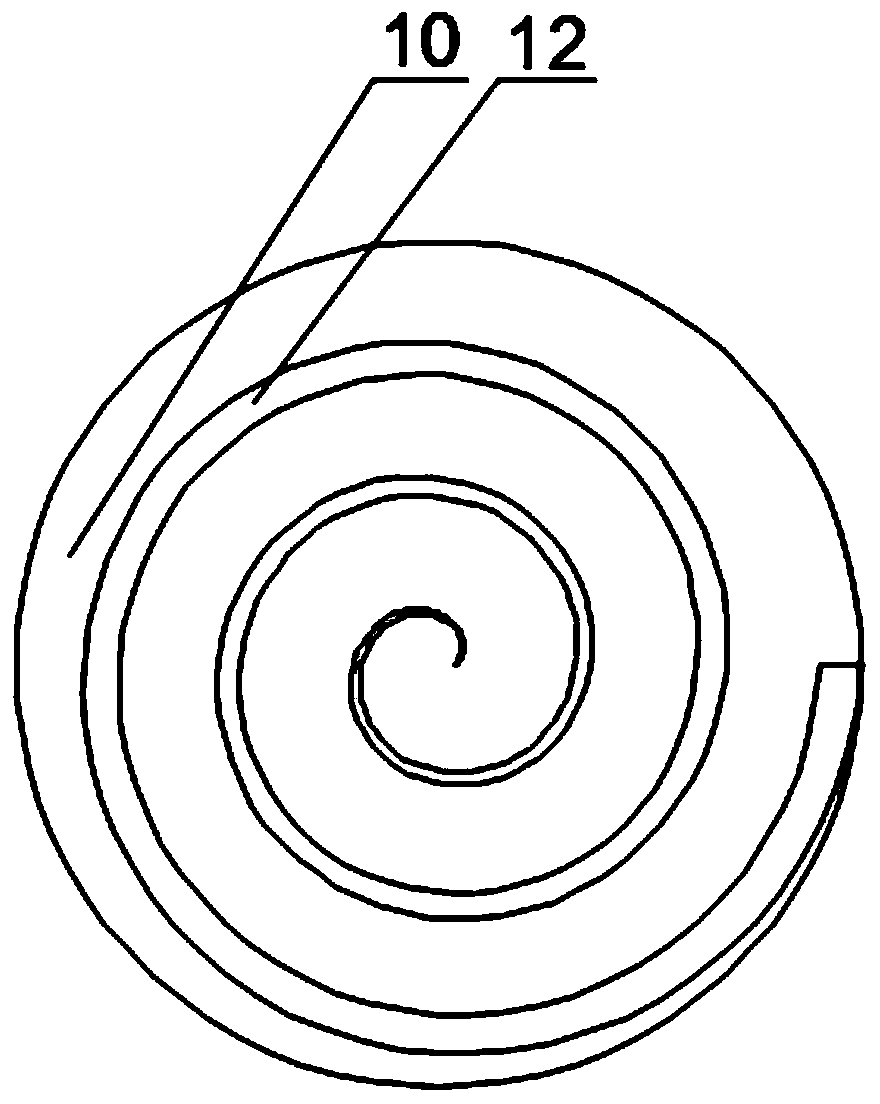

[0024] like Figure 1~4As shown, this embodiment includes a support platform 1 and a plurality of feet 2 arranged at the bottom of the support platform 1, a plurality of grooves are opened on the upper surface of the support platform 1, and a screw 9 moves through the lower surface of the support platform 1 After entering the groove, a circular fixed top plate 10 is installed on the upper end of the screw rod 9, and the outer peripheral wall of the screw rod 9 is provided with a lifting top plate 6 that cooperates with it, and the lifting top plate 6 is placed in the groove. 6 The upper surface is provided with a circular groove 11 coaxial with the screw rod 9, the outer diameter of the fixed top plate 10 is smaller than the inner diameter of the circular groove 11, and the axial depth of the circular groove 11 is greater than the axial depth of the fixed top plate 10 The length also includes a plurality of sleeves 7 arranged at the bottom of the groove, one end of the spring ...

Embodiment 2

[0027] like Figure 1~4 As shown, the upper surface of the fixed top plate 10 in this embodiment is equal to the upper surface of the supporting platform 1 . Further, the upper surface of the fixed top plate 10 is at the same level as the upper surface of the support platform 1, so that when the height of the upper surface of the support platform 1 is exactly the same as the height of the bottom of the inner support beam 4, the height of the inner support beam 4 Two different support surfaces are formed under the bottom, and the interaction between the fixed top plate 10 and the spring 8 can offset the stress generated during cutting to a certain extent, thereby increasing the support stability of the inner support beam 4 .

[0028] Further, the relationship between the axial length of the fixed top plate 10 and the axial depth of the circular groove 11 directly affects the height variation range of the support surface formed by the lifting top plate 6, and the axial length of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com