Construction method for fabricated enclosing wall

A construction method and prefabricated technology, which can be applied to fences, building types, buildings, etc., can solve problems such as the influence of concrete prefabricated sidings, and achieve the effect of reducing post-maintenance times, saving manpower and time, and avoiding damage caused by human factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

[0026] The prefabricated enclosure wall construction can quickly close the substation area and create a good construction environment. The prefabricated components of the prefabricated enclosure mainly include prefabricated columns, prefabricated wall panels and prefabricated roofing.

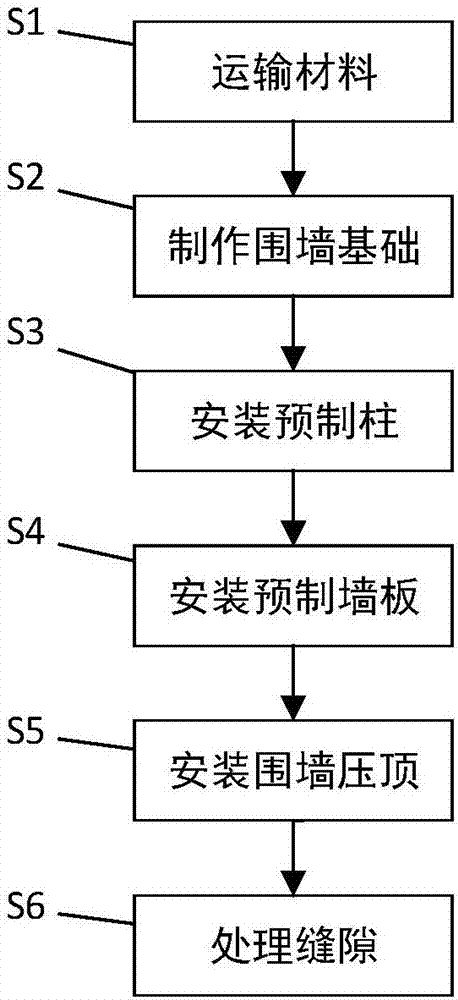

[0027] Such as figure 1 As shown, a prefabricated fence construction method includes the following steps:

[0028] S1. Transportation materials: transport prefabricated columns and prefabricated wall panels to the construction site;

[0029] S2. Make the foundation of the fence: install the steel for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com