A system and method for adding emulsion-type drag-reducing water on site

A drag-reducing water and emulsion type technology, applied in the field of oil and gas field exploration and development, can solve problems such as pipeline blockage and drag-reducing agent injection pump blockage, so as to improve the construction time efficiency, improve the success rate of fracturing, and improve the level of development technology and economy. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

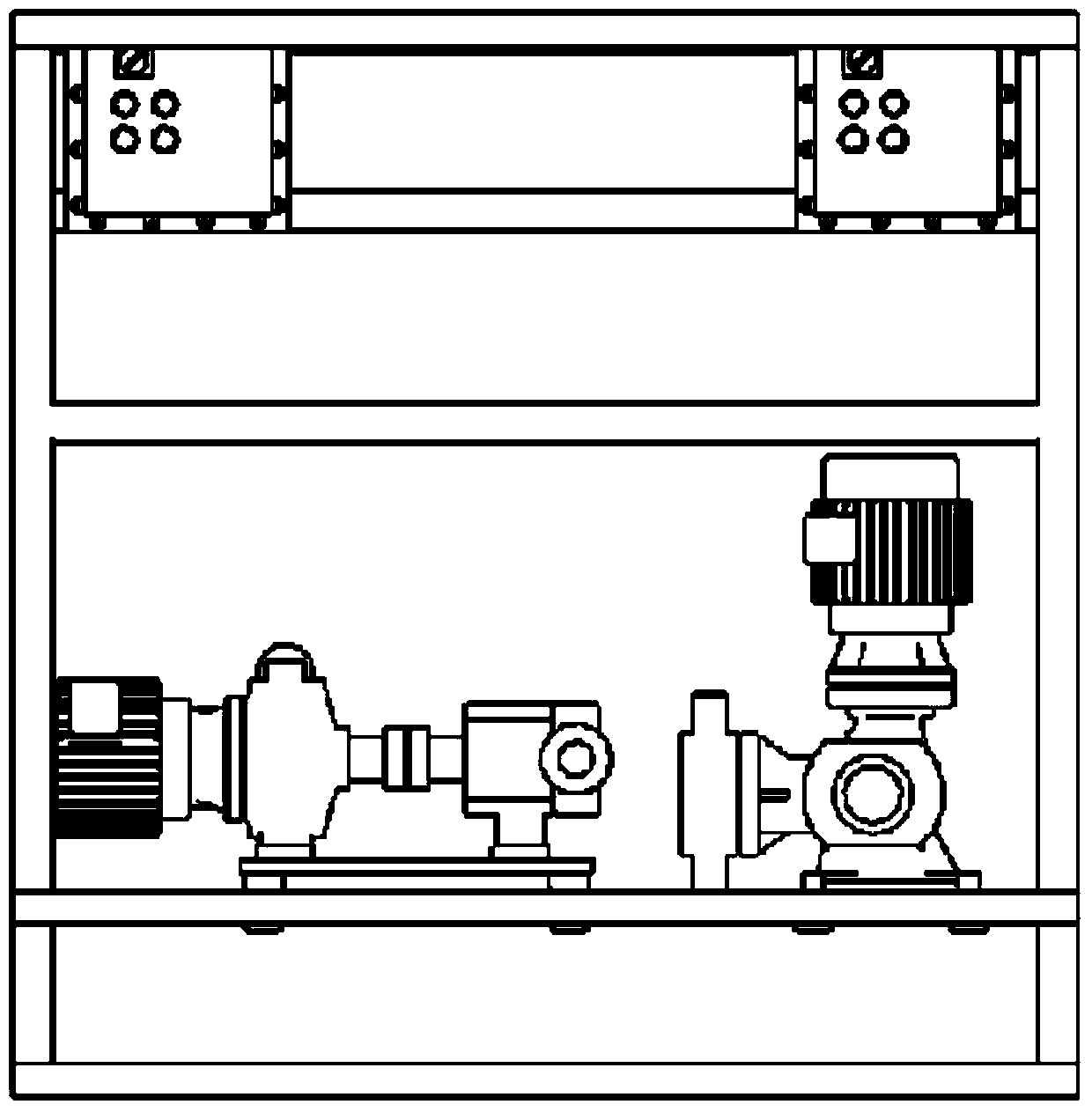

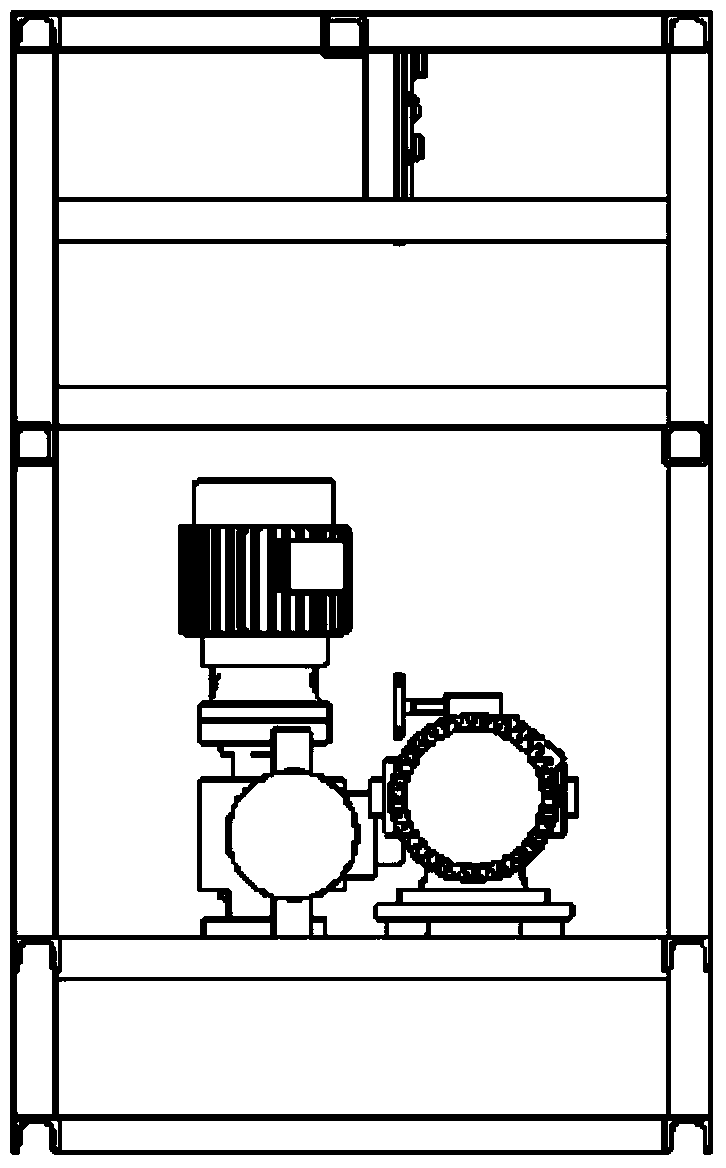

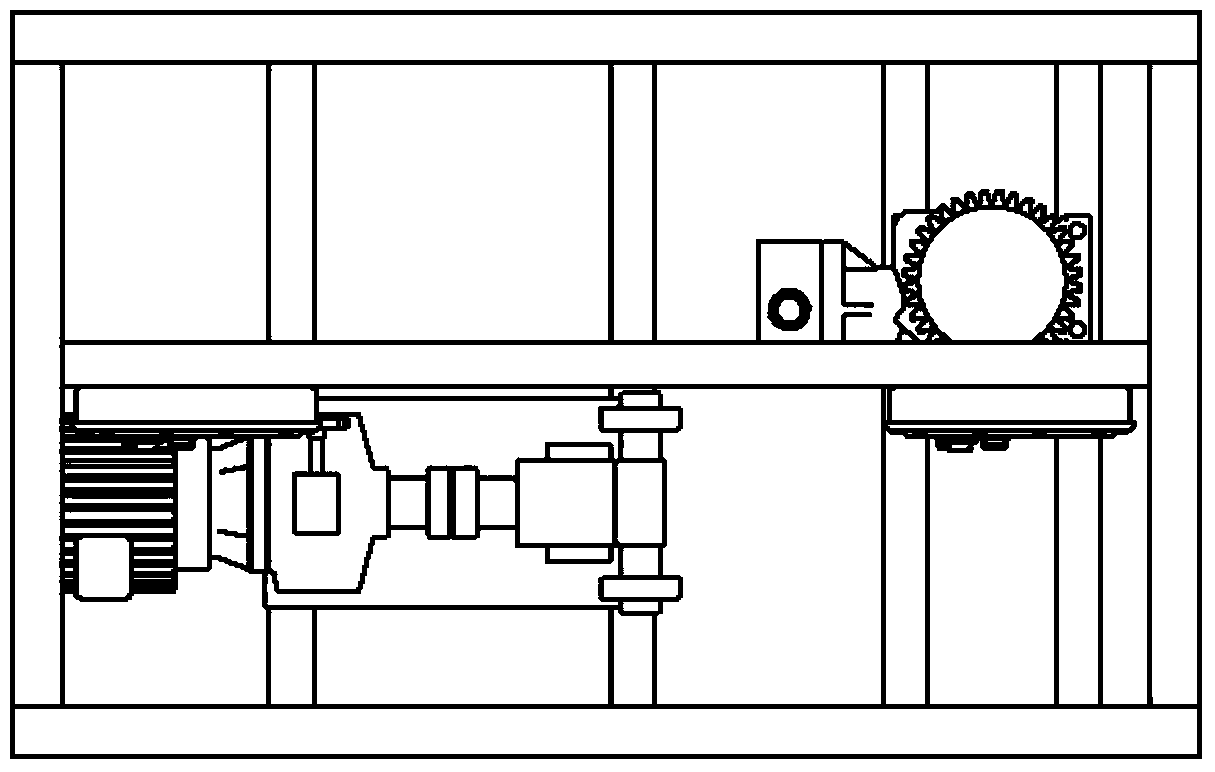

[0039] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0040] On the basis of a comprehensive investigation of the experience and lessons of inhaled emulsion drag reducers in shale gas fracturing construction at home and abroad, with the goal of meeting the large displacement and real-time online mixing in shale gas fracturing construction, in the realization method, use Diaphragm pumps and rotor pumps complement each other. A new type of joint suitable for the manifold of sand mixers has been developed for the fully enclosed closed sand mixers that cannot be mixed with drag reducers, so as to achieve the goal of online mixing of drag reducers with emulsion type drag reducers. It can greatly improve the construction timeliness and greatly reduce the production waste caused by other factors such as rain and fog.

[0041] At first, proportional pumps, plunger pumps and rotor pumps were used in the suction of drag reducers, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com