DMD heat dissipation device

A heat dissipation device and heat technology, applied in the field of projection display, can solve the problems of increasing noise, reducing product reliability, and being unsuitable for small projection equipment, and achieving the effect of reducing noise and increasing product reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

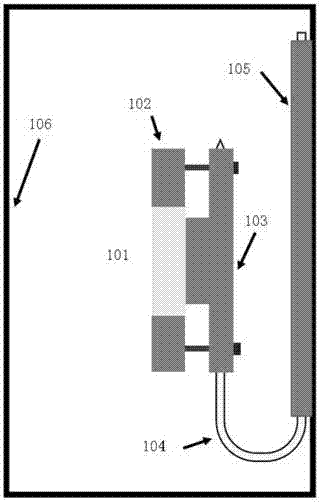

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail by the following examples. It is necessary to point out that this example is only used to further illustrate the present invention, and can not be interpreted as limiting the protection scope of the present invention. Those skilled in the art can according to the above invention Some non-essential improvements and adjustments have been made to the content. In the case of no conflict, the embodiments and the features in the embodiments of the present invention can be combined with each other.

[0024] In addition, some orientation words mentioned in the embodiments of the present invention, such as "left", "right", "upper", "lower", etc., the meaning of these orientation words is related to the installation situation of the heat sink, not It should be understood as a limitation on the protection scope of the present invention.

[0025] A DMD heat sink, such as figure 1 As shown, the device includes: a DMD fixing part 102; a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com