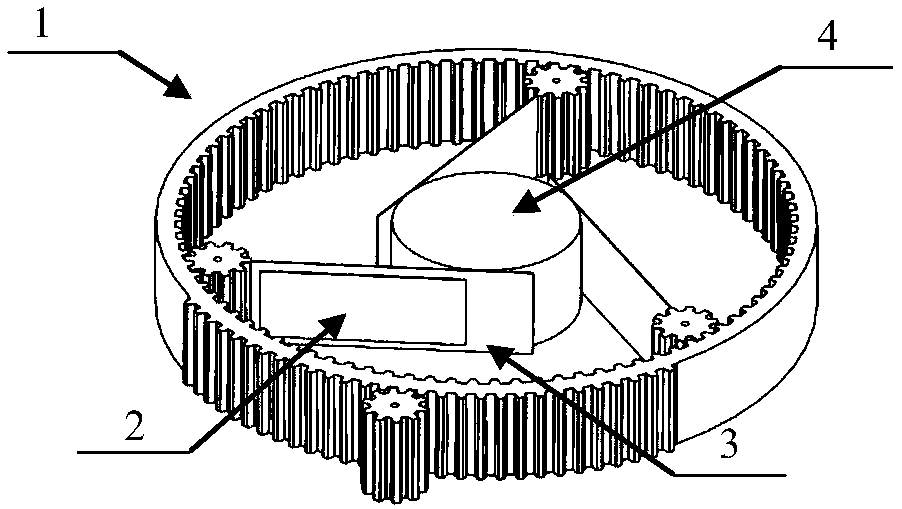

An intelligent clamping device and its active control method

A clamping device and active control technology, applied in workpiece clamping devices, general control systems, control/adjustment systems, etc., can solve problems such as poor applicability, inability to apply clamping force smoothly, and damage to objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

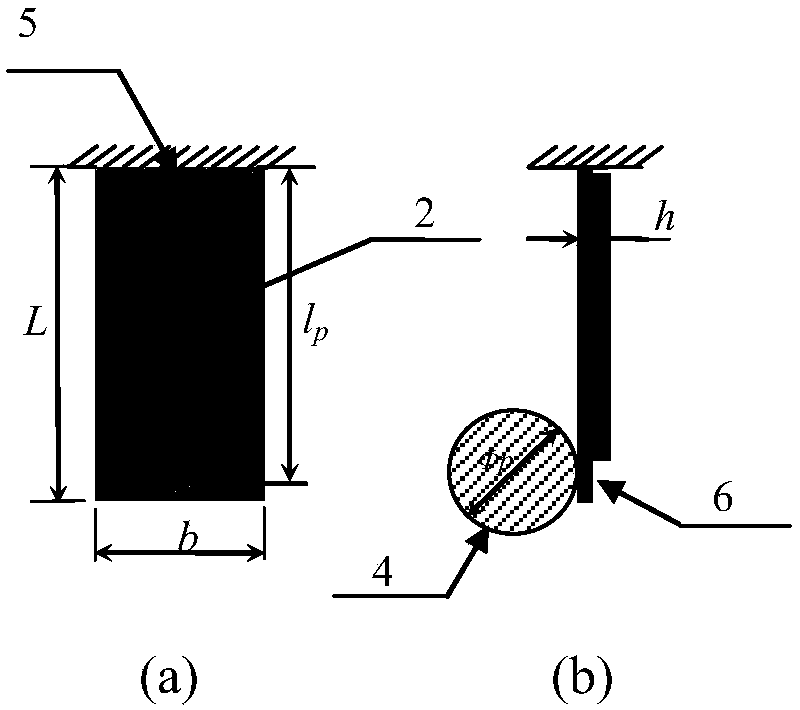

example 1

[0059] A cantilever beam model with a length, width and height of 80 mm, 40 mm and 0.43 mm attached to MFC is used to represent the clamping jaws in the present invention. The material density of the beam is 8110kg / m 3 , the Young's modulus is 200GPa, and the Poisson's ratio is 0.3. Using d33-type (M-5628-P1) type MFC piezoelectric sheet (Smart Material Corp. http: / / www.smart-material.com / MFC-product-main.html), the maximum and minimum operating voltages are respectively +1500V and -500V. The contact point between the object to be clamped and the gripper jaw (ie point p) is located 5mm from the end of the cantilever beam, and the contact load is simulated with a mass.

[0060] The experimental frame is as Image 6 As shown in the figure, Simulink software is used for control in the dSPACE semi-physical real-time control simulation system, KEYENCE LK-G150 sensor is used to measure the deformation, and the control signal is supplied to the MFC piezoelectric sheet after passin...

example 2

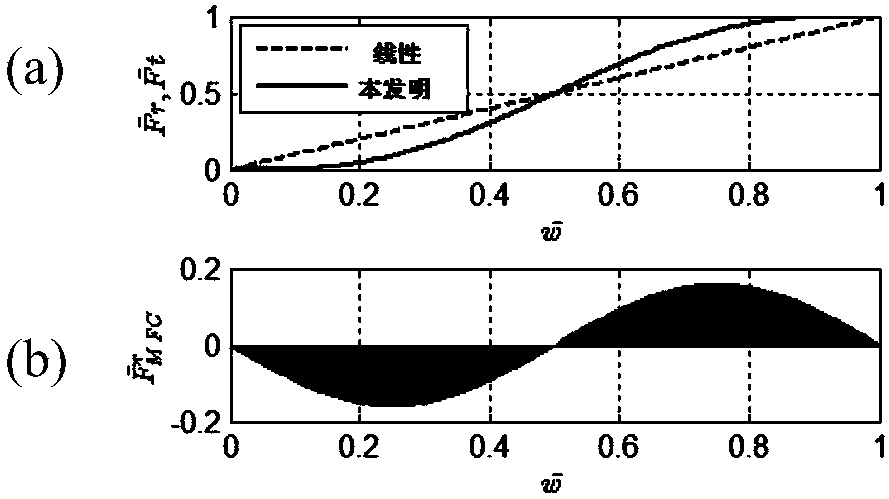

[0067] The second example is realized by simulation. When a single clamping claw exerts a clamping force on the object to be clamped, the change of the acceleration of the contact point of the clamping claw reflects the change of the clamping force. Taking the experimental model in Example 1 as the object, assuming that the outer rotating ring rotates at an angular velocity ω, the deformation at point p changes linearly from 0 to w within 2s g , using the parameters obtained by the finite element method in Table 1 to carry out numerical simulation verification. In order to illustrate the effect of gentle clamping of the present invention, a comparison is made with the acceleration response (ie, the acceleration during the clamping process of the clamped object) of the clamping jaw at point p in the process with a clamping jaw with a fixed clamping stiffness (ie, a linear case). The result of feedforward control is Figure 8 , it can be seen that the acceleration response in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com