Gas cabinet control system and method

A control system and gas cabinet technology, applied in general control systems, control/regulation systems, electrical program control, etc., can solve the problems of poor reliability, production impact, and high system costs, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

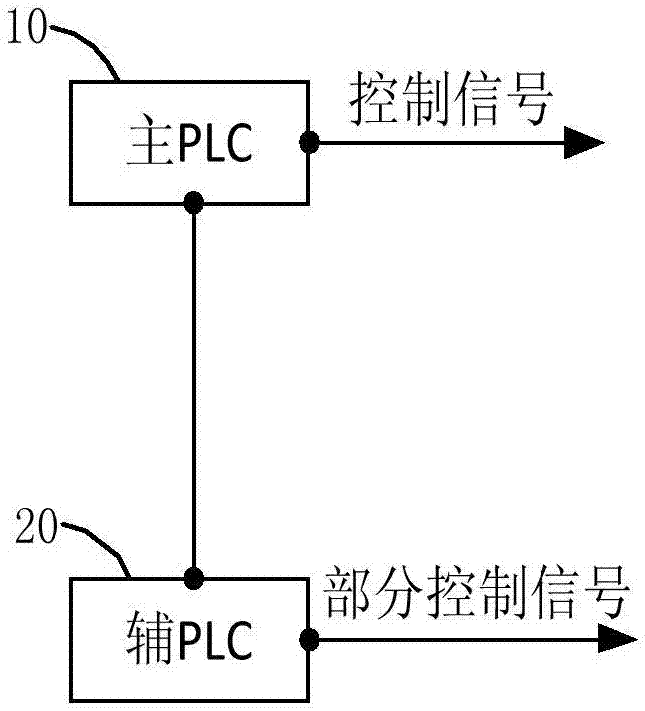

[0021] figure 1 It is a schematic diagram of a gas cabinet control system provided in Embodiment 1 of the present invention. The control system can be applied to a gas supply system, but is not limited to a gas supply system. The system is controlled by the auxiliary PLC and the main PLC in cooperation with each other. see figure 1 , the gas cabinet control system includes:

[0022] The main PLC10 is used to perform the air supply control function in the working state;

[0023] Auxiliary PLC 20, connected with the main PLC 10, is used to monitor the failure of the main PLC 10 in the follow-up operation state, then switch from the follow-up operation state to the temporary operation state, and is used to execute a part in the temporary operation state Air supply control function.

[0024] Among them, the main PLC10 can be OMRON CJ series; the working state of the main PLC10 refers to the normal operation state; the fault state of the main PLC10 refers to the stop operation...

Embodiment 2

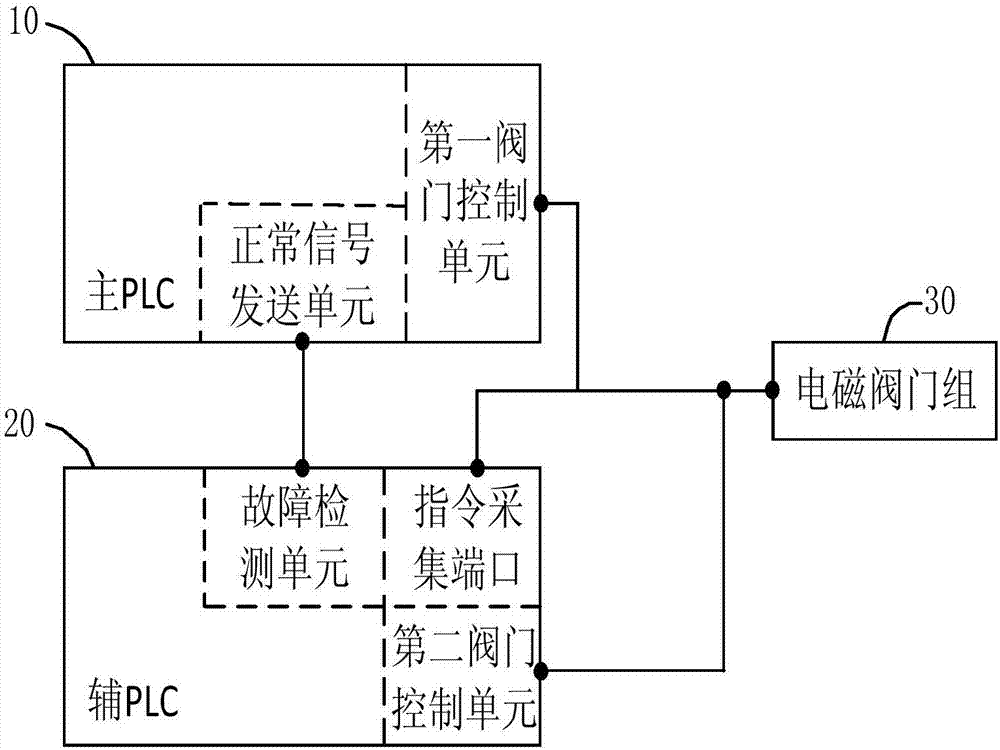

[0029] figure 2 It is a schematic diagram of a gas cabinet control system provided by Embodiment 2 of the present invention. This embodiment is an optimization of the foregoing embodiments.

[0030] see figure 2 , in this embodiment, the main PLC 10 includes a first valve control unit, which is connected to each valve in the electromagnetic valve group 30, and is used to send a valve control signal to each of the valves to control each of the valves. The switching state of the valve. The primary PLC 10 also includes a normal signal sending unit, configured to send a normal signal to the secondary PLC 20 in a normal working state.

[0031] The auxiliary PLC20 includes: a fault detection unit, which is connected to the main PLC10, and is used to monitor the failure of the main PLC10 in the follow-up operation state. Specifically, when a normal signal cannot be received, it is determined that the main PLC10 is faulty, Then switch from the following running state to the temp...

Embodiment 3

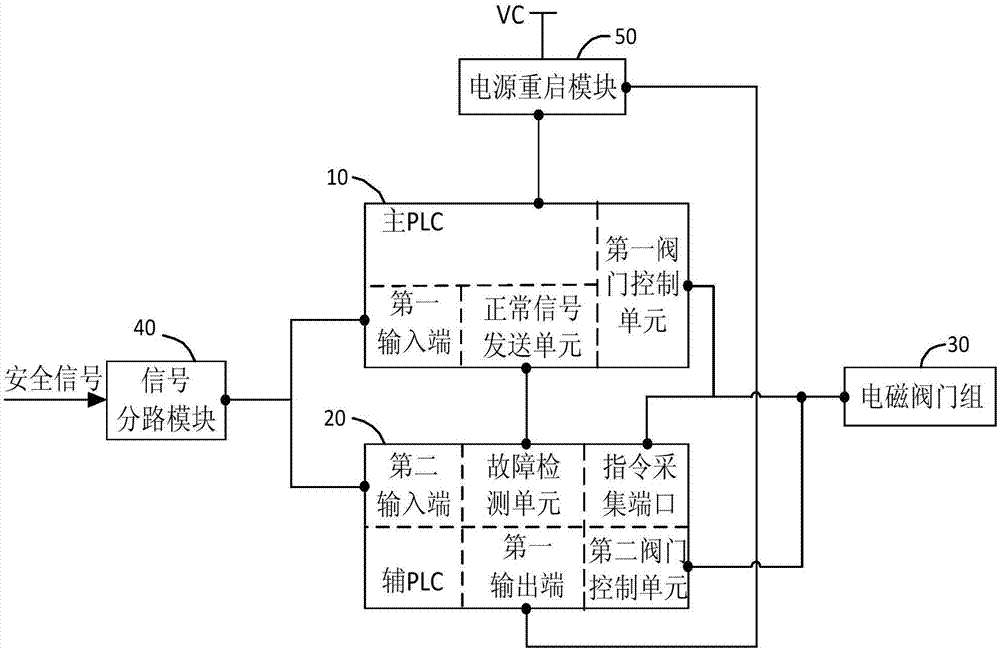

[0038] image 3 It is a schematic diagram of a gas cabinet control system provided by Embodiment 3 of the present invention. This embodiment is an optimization of the foregoing embodiments.

[0039] see image 3 , in this embodiment, the gas cabinet control system also includes:

[0040] The signal branching module 40 is used to receive the input safety signal, branch it into at least two safety signals, and output it from the signal output terminal. The signal branching module 40 may be a relay. When receiving an input safety signal, the electromagnetic coil of the relay is charged, causing multiple contacts of the relay to close, and completing the branching of the safety signal. The safety signal includes at least one of the following: emergency stop signal, fire alarm signal, high temperature switch signal and gas leakage signal.

[0041] Optionally, the main PLC 10 also includes a first input terminal, which is connected to the signal output terminal of the signal bra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap