Three-dimensional memory manufacturing method and structure thereof

A memory, three-dimensional technology, applied in electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of contact failure, uncontrollable wafer stress, affecting the robot to grasp the wafer, etc., to reduce wafer bending, improve The effect of macroscopic stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] refer to Figure 5-10 As shown, Embodiment 1 of the present invention proposes a method for preparing a three-dimensional memory, which is characterized in that it includes the following steps:

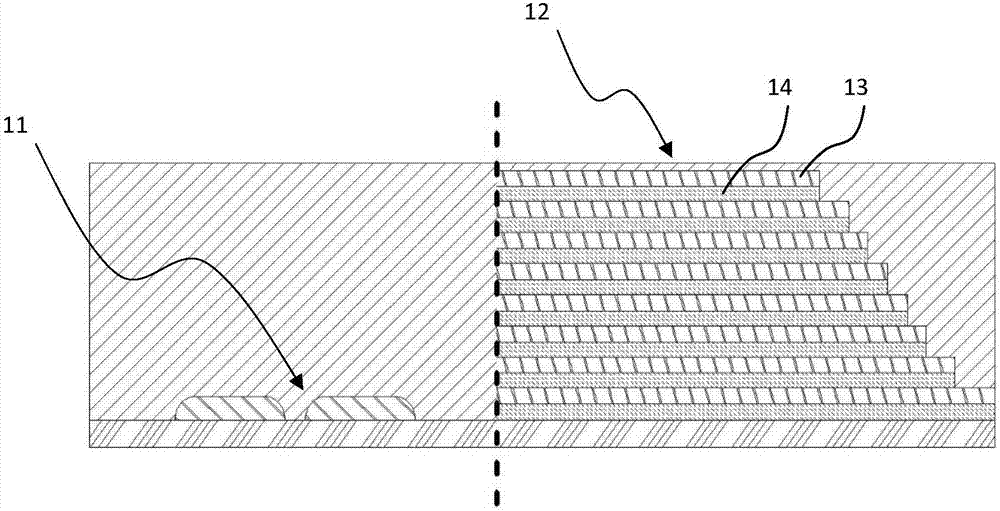

[0031] Such as Figure 5 As shown, a substrate 20 is provided, on which a peripheral circuit area 21 and an array storage area 22 of a three-dimensional memory are formed; preferably, forming the array storage area 22 includes alternately forming silicon nitride on the substrate 20 A multilayer stack structure of layer 23 and silicon oxide layer 24; using a photolithography process to form a step region 25 on at least one side of the multilayer stack structure so that a part of the upper surface of each silicon nitride layer 23 is exposed to the step region 25.

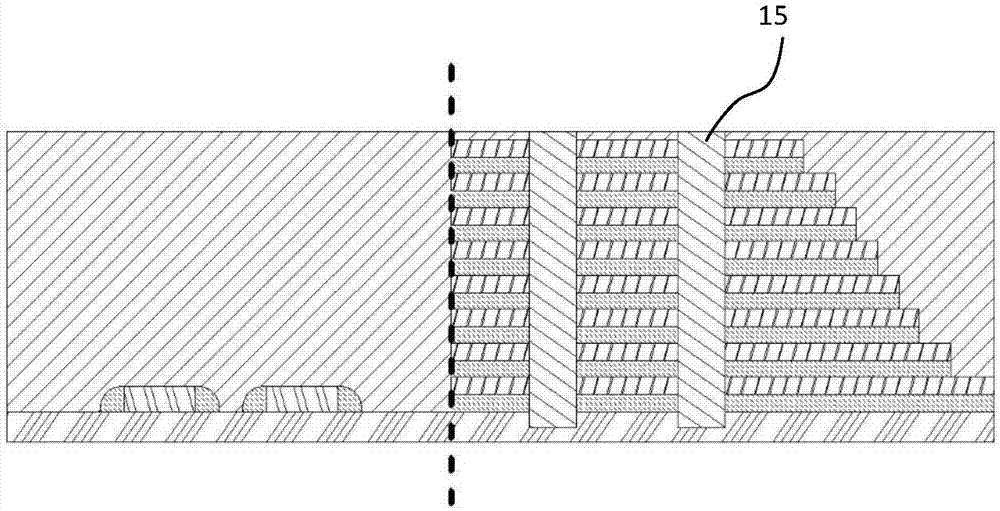

[0032] Forming an insulating layer 26 with a flat surface on the substrate 20 to cover the peripheral circuit area 21 and the array storage area 22;

[0033] Such as Image 6 As shown, the insulating layer 26 on th...

Embodiment 2

[0038] Embodiment 2 of the present invention proposes a method for preparing a three-dimensional memory, which is characterized in that it includes the following steps:

[0039] Such as Image 6As shown, preferably, after the insulating layer 26 on the peripheral circuit region 21 is patterned, etched and filled with metal to form a plurality of first contact holes 27 electrically connected to the peripheral circuit region 21, It also includes the step of performing a chemical mechanical mask on the surface of the substrate 20 .

[0040] Such as Figure 7 As shown, preferably, after the step of performing a chemical mechanical mask on the surface of the substrate 20, a step of depositing a silicon dioxide cap layer 31 on the substrate 20 is also included to protect the first contact hole 27 The metal fill in is not damaged by subsequent processes.

[0041] Preferably, the thickness of the silicon dioxide cap layer is greater than 3000 angstroms.

Embodiment 3

[0043] Embodiment 3 of the present invention proposes a method for manufacturing a three-dimensional memory. In this embodiment, parts different from the above embodiments will be described, and the same parts will not be repeated.

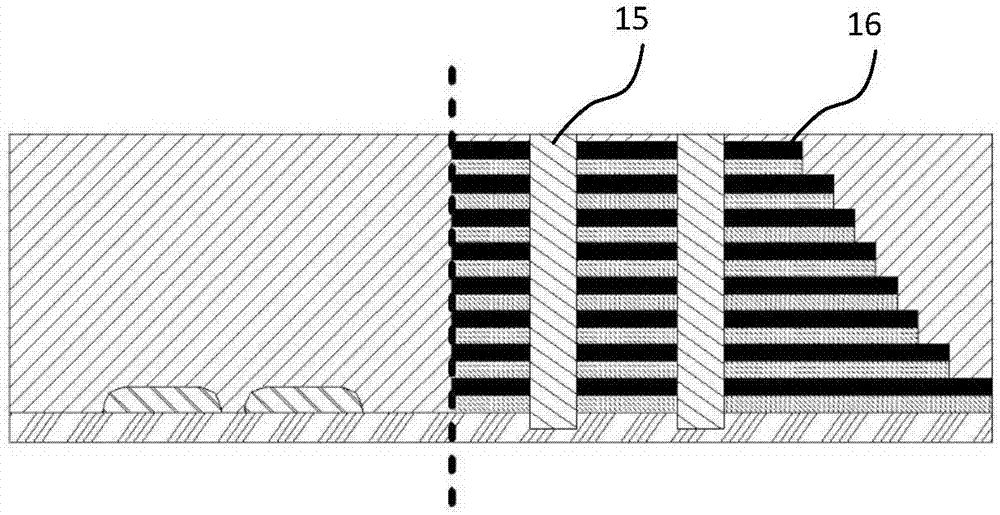

[0044] Such as Figure 9 As shown, preferably, after forming the metal gate 29 of the memory cell in the array storage region 22 , a step of depositing a silicon dioxide filling layer 32 on the silicon dioxide cap layer 31 is also included.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com