A kind of sealing method of on-cell product and its binding area

An ON-CELL, binding area technology, applied in the sealing field of ON-CELL products and their binding areas, can solve problems such as poor sealing, and achieve the effect of extending service life, avoiding product defects, and enhancing reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

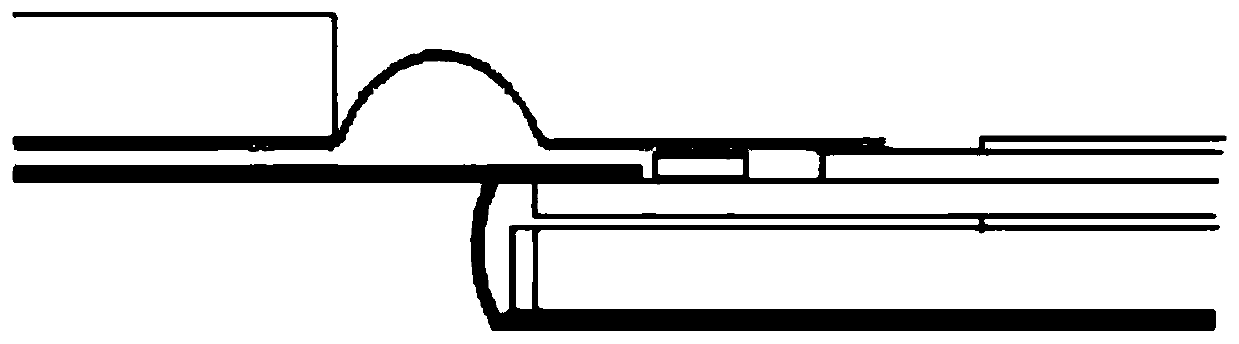

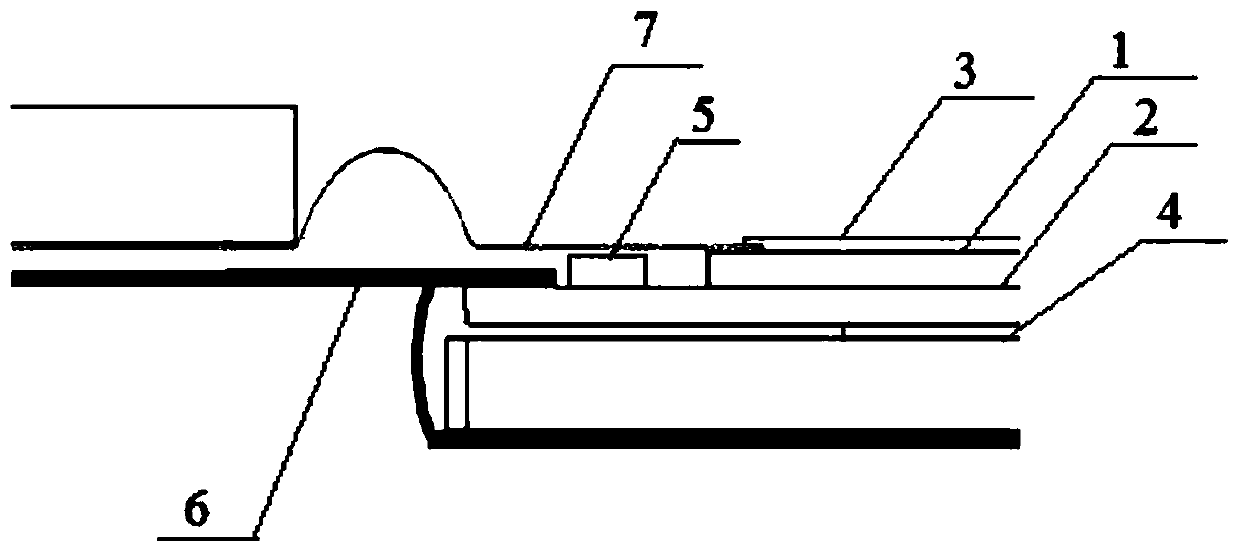

[0041] Example 1, such as figure 2 As shown, the sealing method of a kind of ON-CELL product binding area of the first embodiment of the present invention comprises:

[0042] Step 1, prepare TFT upper glass 1 and TFT lower glass 2, and the width of TFT lower glass 2 is greater than the width of TFT upper glass 1;

[0043] Step 2, attaching a lower polarizer 4 on the lower surface of the TFT lower glass 2;

[0044] Step 3, cleaning the terminals of the TFT lower glass 2, binding the driving integrated circuit IC5 on the upper surface of the TFT lower glass 2, and the driving integrated circuit IC5 is not in contact with the TFT upper glass 1;

[0045] Step 4, bind the lower glass binding pins on the upper surface of the TFT lower glass 2, bind the lower glass FPC6 to the lower glass binding pins, and the driving integrated circuit IC5 is not in contact with the lower glass FPC6;

[0046] Step 5: Clean the terminals of TFT upper glass 1, bind the upper glass binding pins on...

Embodiment 2

[0065] Embodiment 2, a kind of ON-CELL product described in the embodiment of the present invention, such as figure 2 shown, including:

[0066] TFT lower glass 2, lower polarizer 4 arranged on the lower surface of TFT lower glass 2, driving integrated circuit IC5 bound to the upper surface of TFT lower glass 2, lower glass binding pins bound to the upper surface of TFT lower glass 2 , the lower glass FPC6 bound to the lower glass binding pin;

[0067] TFT upper glass 1, upper polarizer 3 arranged on the upper surface of TFT upper glass 1, upper glass binding pins bound on the upper surface of TFT upper glass 1, upper glass FPC7 bound on the upper glass binding pins ;

[0068] The width of TFT lower glass 2 is greater than that of TFT upper glass 1;

[0069] The sealing line glue provided at the upper glass binding pin and the lower glass binding pin;

[0070] A sealing material provided between the end of the upper polarizer 3 and the end of the upper glass FPC7.

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com