Magnet fixing frame and voice coil motor using same

A magnet fixed, voice coil motor technology, applied in the direction of magnetic circuit static parts, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of low assembly yield, unstable assembly structure, difficult magnetic Stable placement of components and other issues to improve assembly efficiency and avoid defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

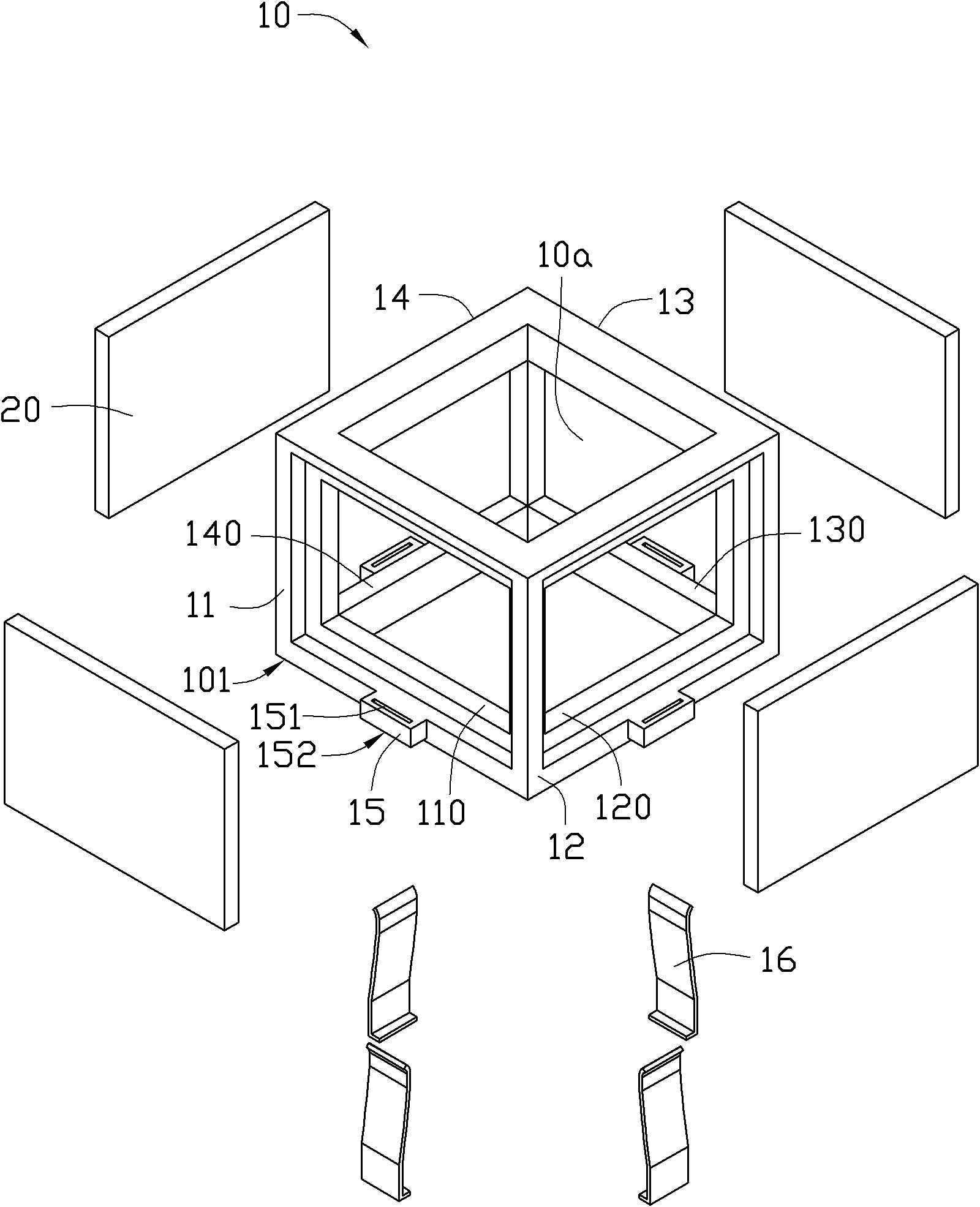

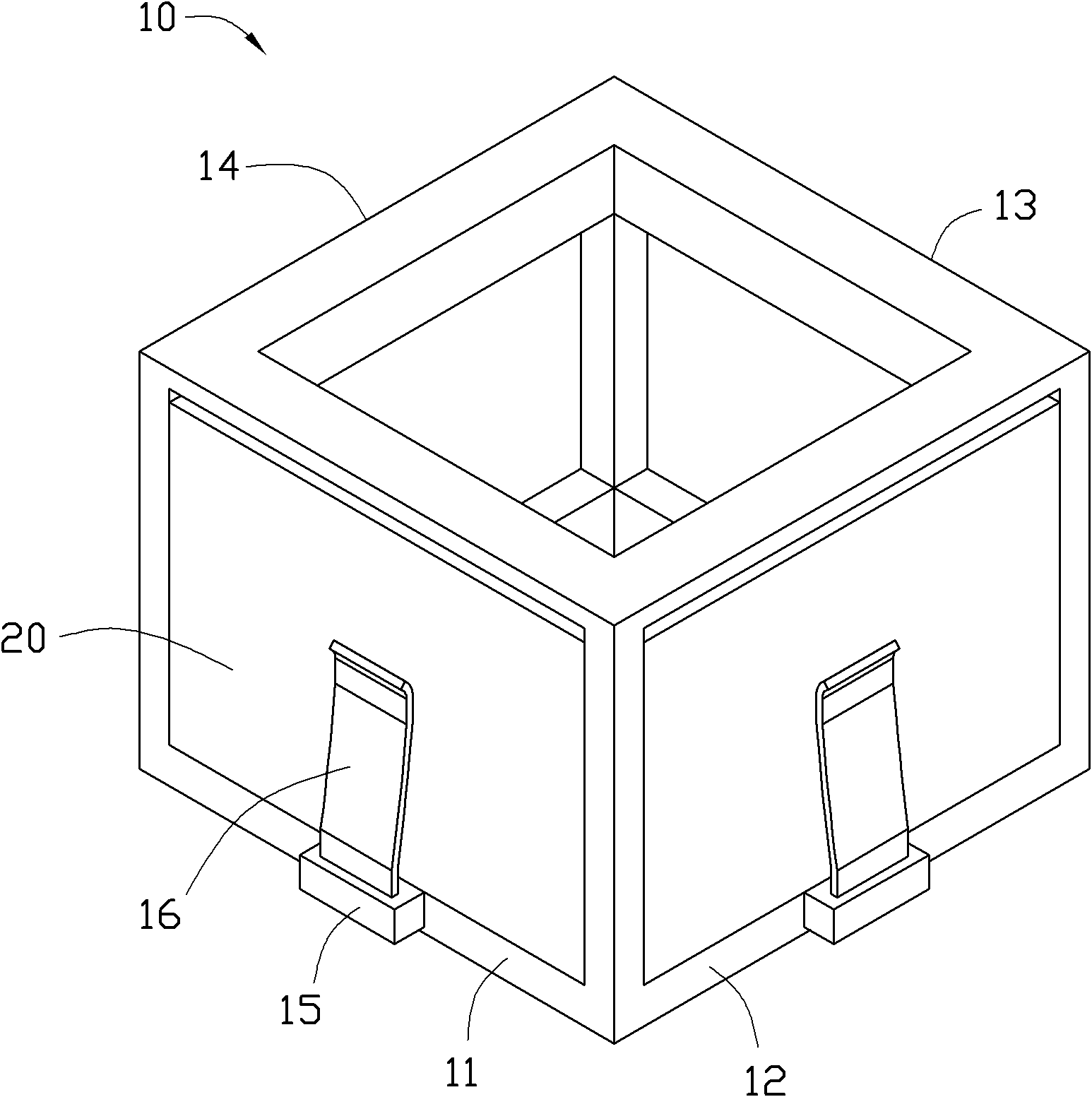

[0040] see figure 1 , The magnet fixing frame 10 provided by the first embodiment of the present invention is used to fix the magnet in the voice coil motor, which is roughly a square frame. It can be understood that the magnet holder 10 can also be in other shapes, such as a circle or other polygons.

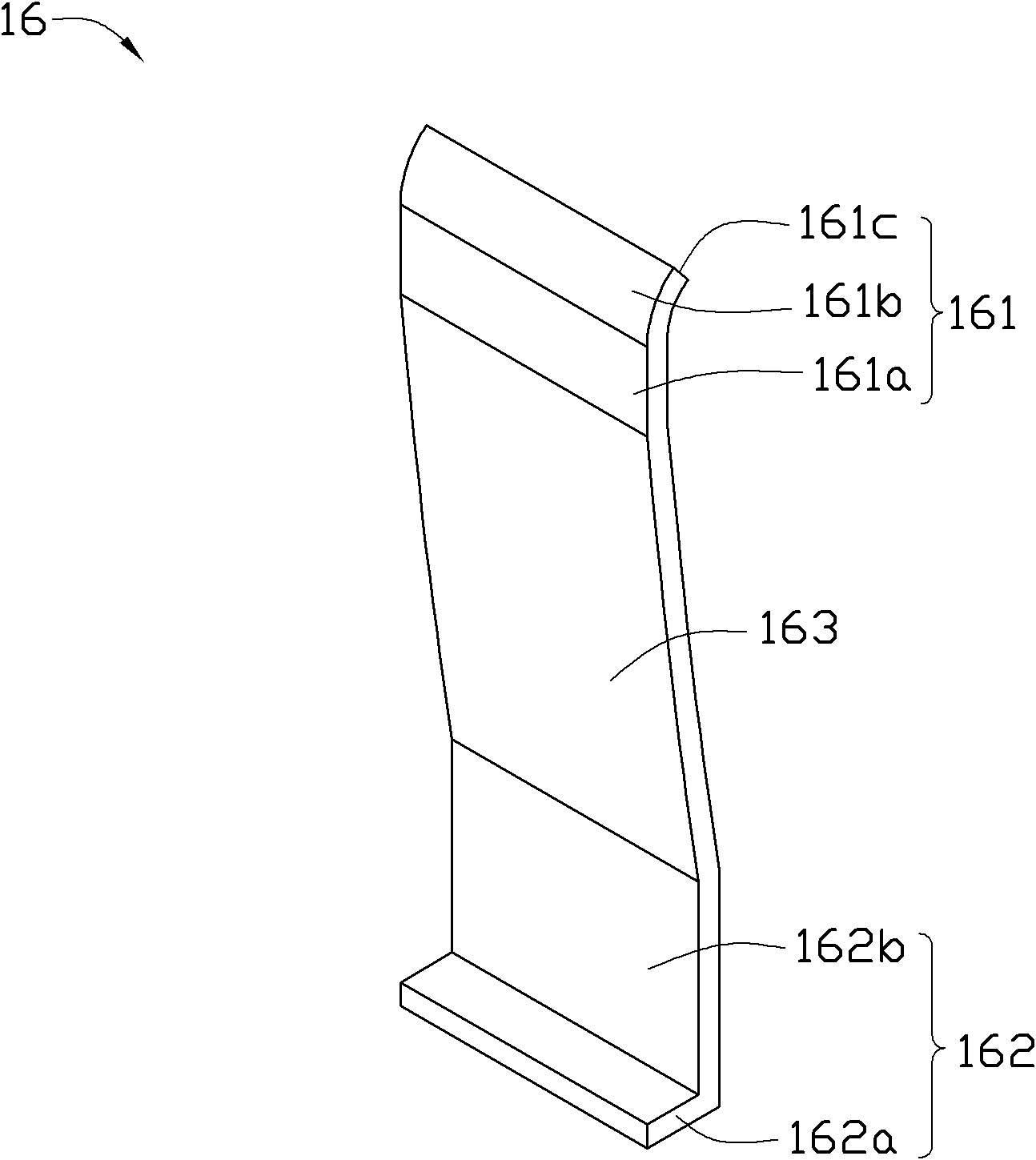

[0041] The magnet holder 10 includes a first side wall 11 , a second side wall 12 , a third side wall 13 , a fourth side wall 14 and four resisting elastic pieces 16 . The first side wall 11 , the second side wall 12 , the third side wall 13 , and the fourth side wall 14 connect end to end to form a receiving space 10 a. Wherein, the first side wall 11 is opposite to the third side wall 13 , and the second side wall 12 is opposite to the fourth side wall 14 .

[0042] The first sidewall 11 defines a first stepped hole 110 . The second sidewall 12 defines a second stepped hole 120 . The third sidewall 13 defines a third stepped hole 130 . The fourth sidewall 14 defines a fo...

no. 2 approach

[0051] see Figure 4 , is the voice coil motor 1 provided by the second embodiment of the present invention, the voice coil motor 1 includes a casing 30 and the magnet fixing frame 10 , and the magnet fixing frame 10 is fixed in the casing 30 .

[0052] The above-mentioned magnet fixing frame abuts and fixes the magnet through the resisting elastic piece, and only needs to install the resisting elastic piece during assembly, which can improve assembly efficiency and avoid product defects caused by glue dispensing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com