An automatic egg harvesting device for cage farming

An automatic and equipment technology, applied in the poultry industry, poultry cages or houses, applications, etc., can solve the problems of high cost, introduction of germs, time-consuming and labor-intensive problems, so as to reduce the dependence on manpower, improve product quality, and ensure breeding safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

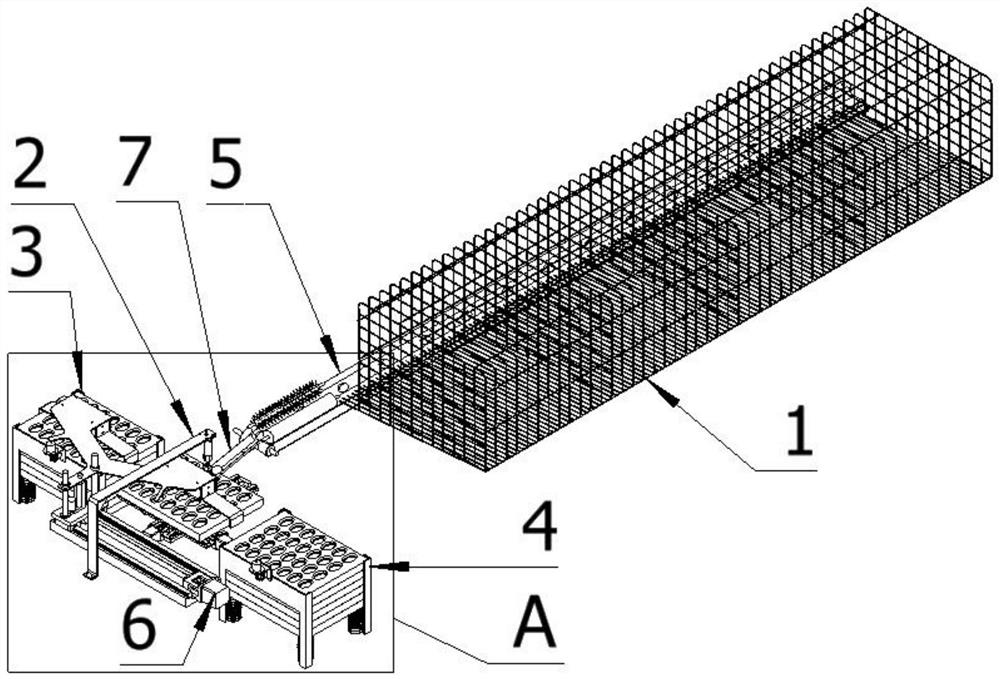

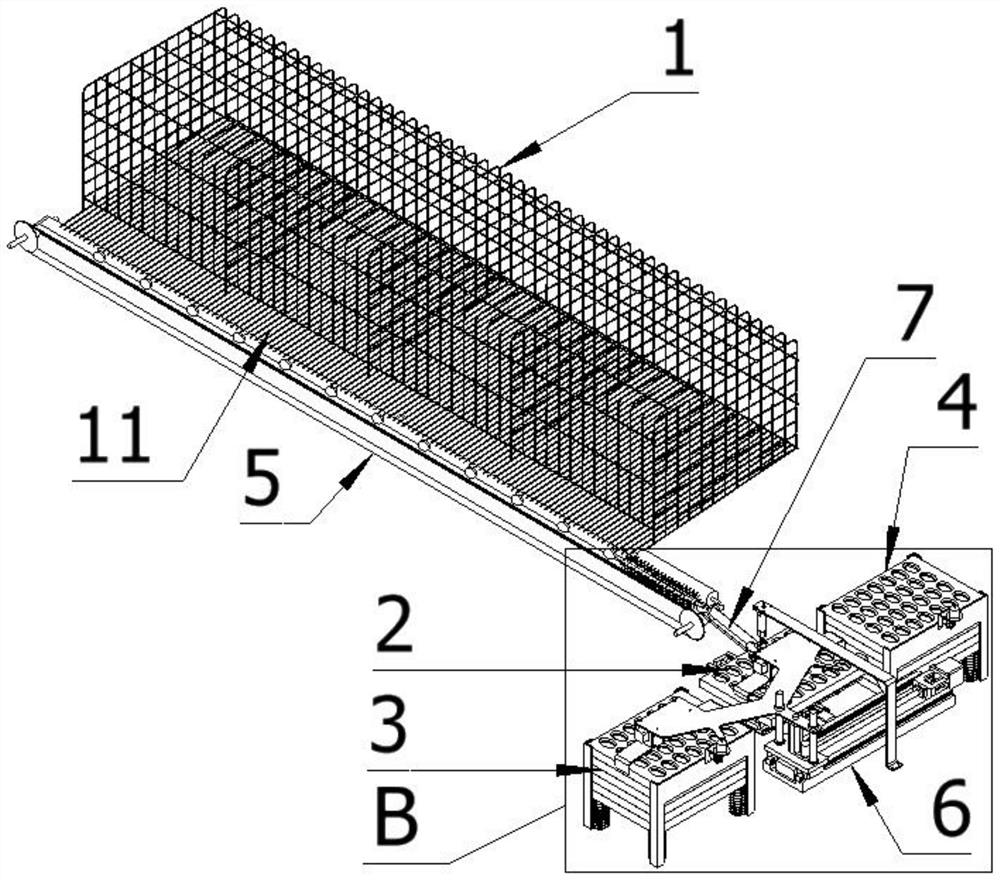

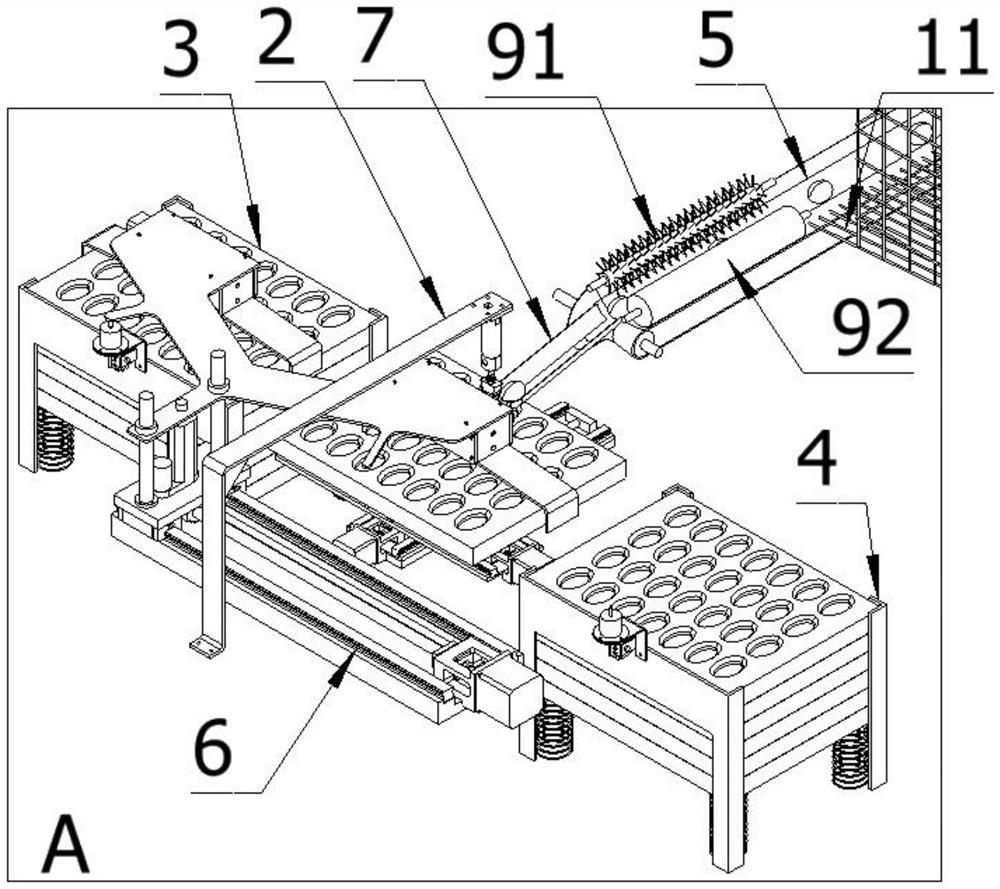

[0034] Figure 1 to Figure 12 It is an embodiment of the present invention. As shown in the figure, a kind of automatic egg collection equipment for cage farming is used to collect the eggs in the breeding cage 1. The breeding cage 1 is provided with a slope slide 11. The automatic Egg collecting equipment includes egg collecting mechanism 2, conveyor belt 5, elastic egg tray 7, such as image 3 , Figure 4 As shown, the conveyor belt 5 is docked with the end of the slope slideway 11, and the cross section of the conveyor belt 5 is spoon-shaped;

[0035] Such as Figure 5 As shown, the elastic egg tray 7 includes a supporting plate 71 and a bracket 72. Two supporting plates 71 are arranged symmetrically. Rod 74, supporting plate 71 is provided with the guide sleeve 75 corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com