Warehouse defective product placement rack for integrated circuit testing

A technology of integrated circuits and placement racks, applied in the field of placement racks, can solve the problems of littering and disposing of defective integrated circuits, difficulty in recycling and reusing defective integrated circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

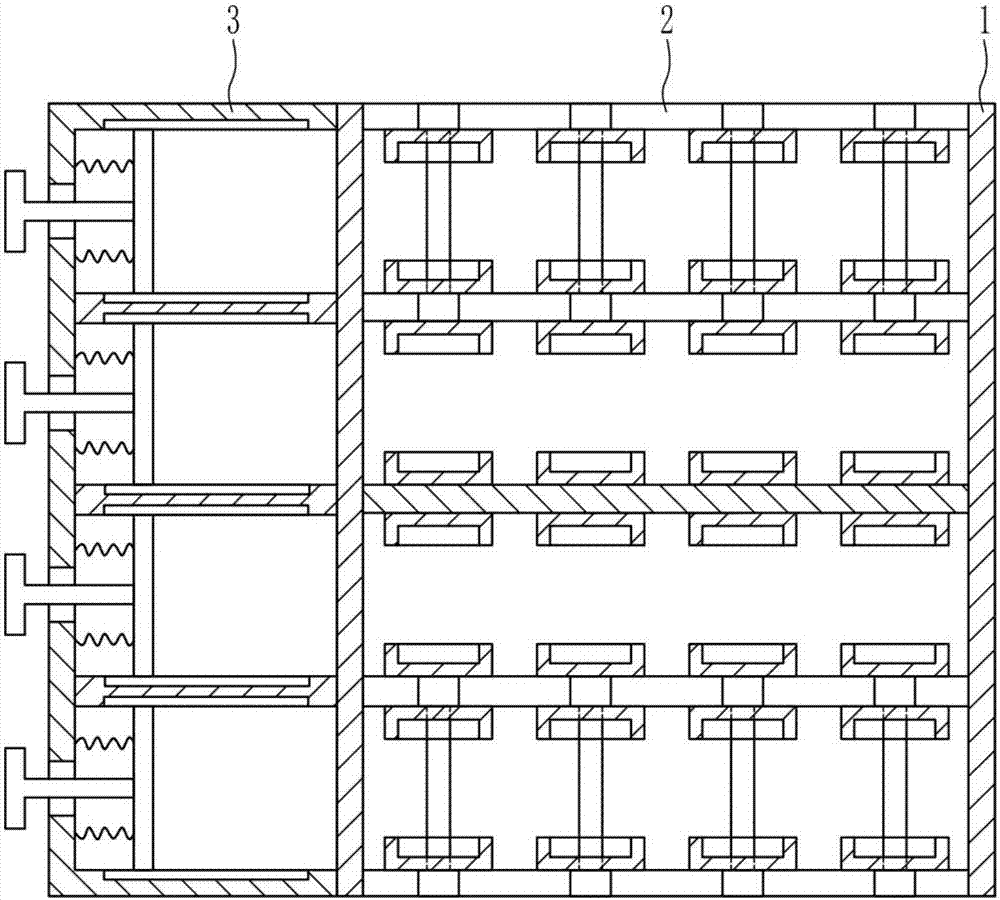

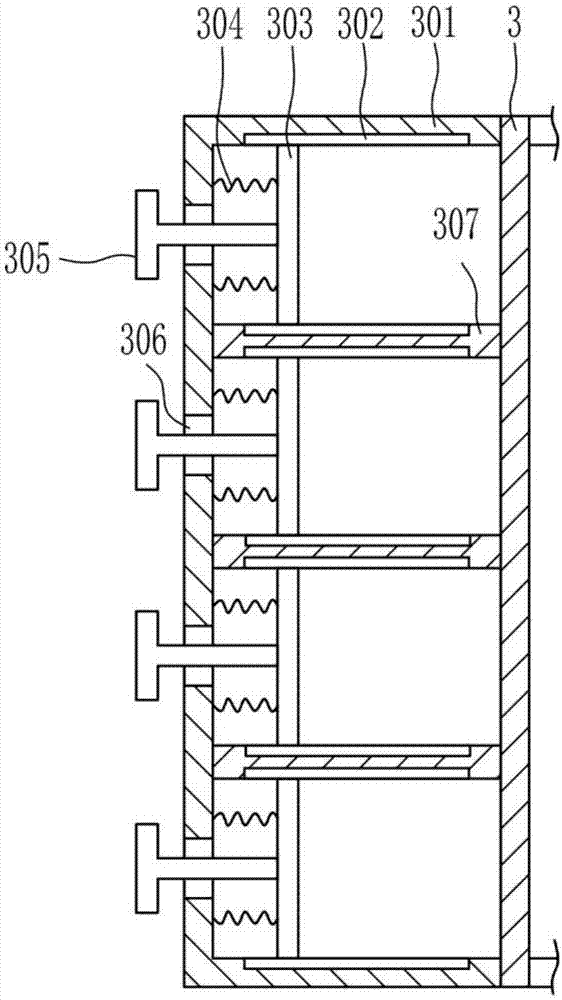

[0036] A warehouse defective product placement rack for integrated circuit testing, such as Figure 1-7 As shown, it includes a placement frame 1, a placement mechanism 2 and a warning mechanism 3, the placement mechanism 2 is connected in the placement frame 1, and the warning mechanism 3 is connected to the left end of the placement frame 1.

Embodiment 2

[0038] A warehouse defective product placement rack for integrated circuit testing, such as Figure 1-7 As shown, it includes a placement frame 1, a placement mechanism 2 and a warning mechanism 3, the placement mechanism 2 is connected in the placement frame 1, and the warning mechanism 3 is connected to the left end of the placement frame 1.

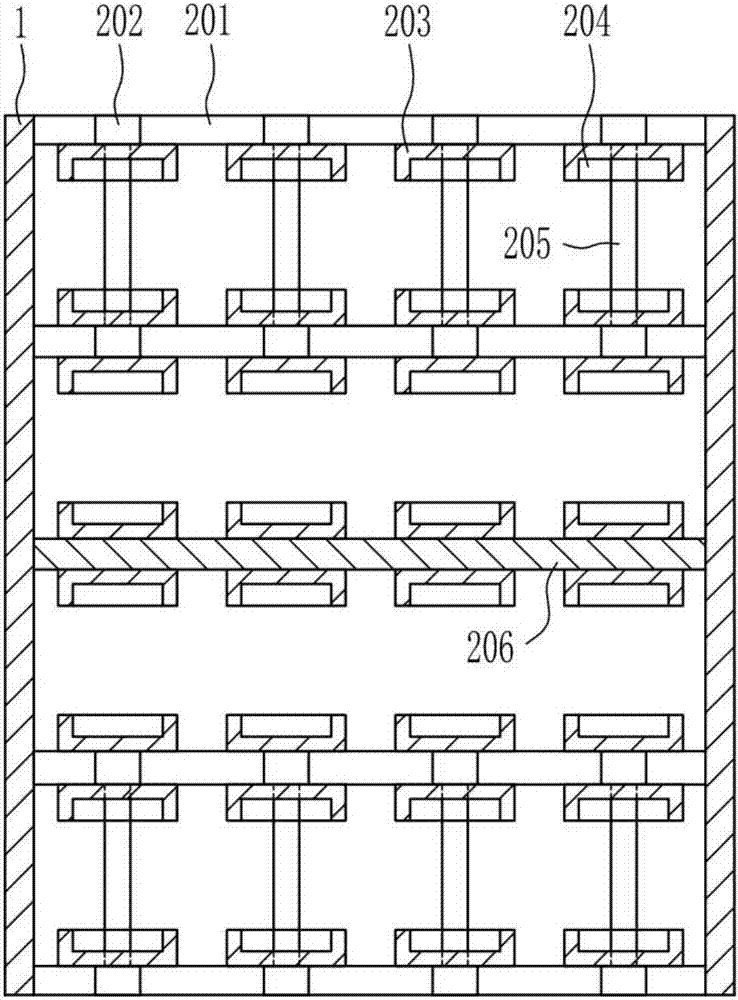

[0039] The placing mechanism 2 includes a first sliding rail 201, a first sliding block 202, a clamping block 203, a connecting rod 205 and a first partition 206, and the upper and lower walls of the placing frame 1 are symmetrically connected with the first sliding rail 201 up and down. , the first slide rails 201 on the upper and lower sides of the upper wall and the lower wall are slidably connected with the first slider 202 evenly, and the first sliders 202 cooperate with the first slide rails 201 on the upper and lower sides of the upper wall and the lower wall, The number of the first sliders 202 on the first slide rail 201 is fo...

Embodiment 3

[0041] A warehouse defective product placement rack for integrated circuit testing, such as Figure 1-7 As shown, it includes a placement frame 1, a placement mechanism 2 and a warning mechanism 3, the placement mechanism 2 is connected in the placement frame 1, and the warning mechanism 3 is connected to the left end of the placement frame 1.

[0042] The placing mechanism 2 includes a first sliding rail 201, a first sliding block 202, a clamping block 203, a connecting rod 205 and a first partition 206, and the upper and lower walls of the placing frame 1 are symmetrically connected with the first sliding rail 201 up and down. , the first slide rails 201 on the upper and lower sides of the upper wall and the lower wall are slidably connected with the first slider 202 evenly, and the first sliders 202 cooperate with the first slide rails 201 on the upper and lower sides of the upper wall and the lower wall, The number of the first sliders 202 on the first slide rail 201 is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com